Centripro, Residential water systems, Wire centripro motor data – Xylem BMAID R4 User Manual

Page 8

PAGE 8

Residential Water Systems

CentriPro

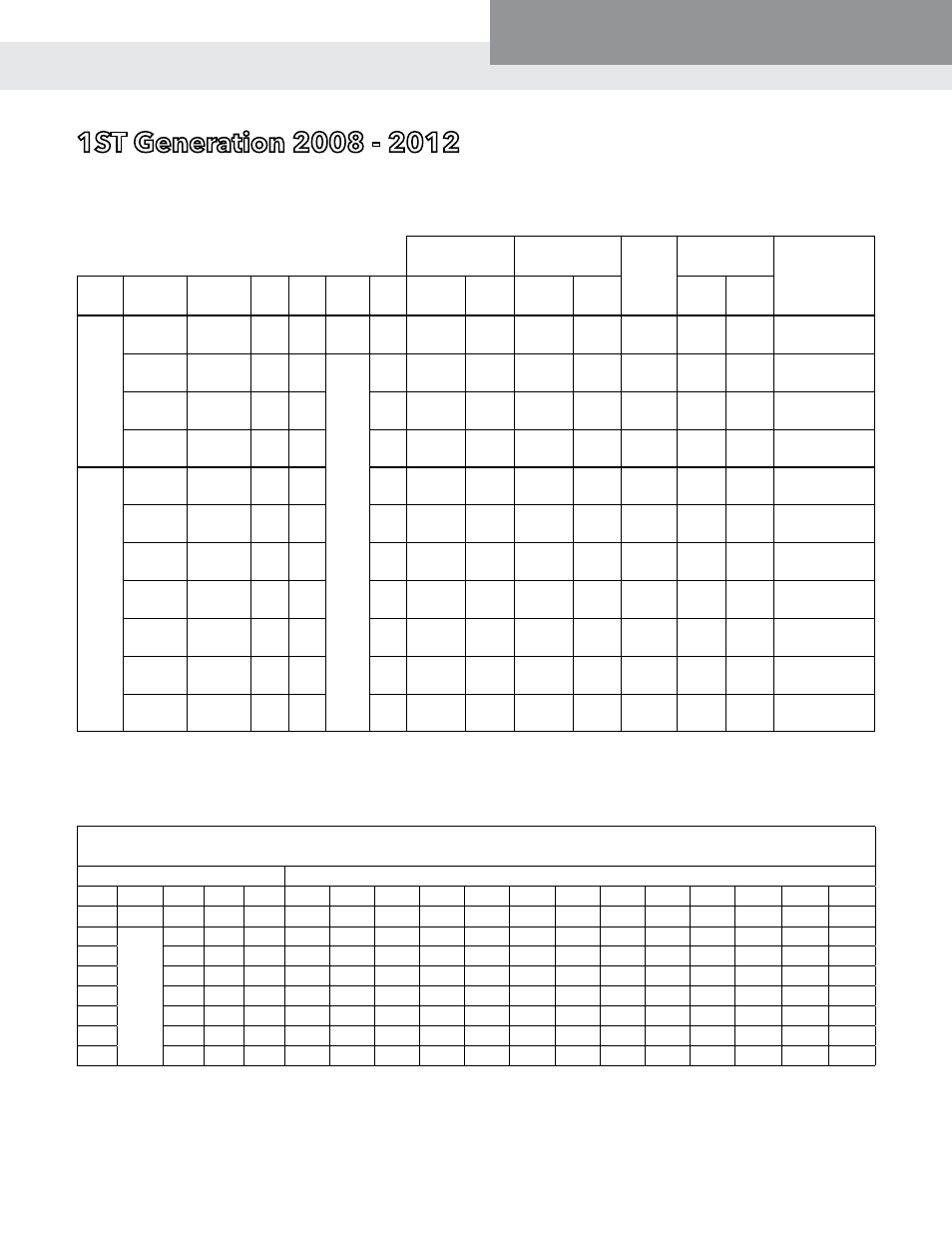

3-wIrE, SINGlE phaSE 4" motorS - ElECtrICal Data, 60 hErtz, 3450 rpm

1St Generation 2008 - 2012

3-wIrE CENtrIpro motor Data

full load

Service factor locked

rotor

amps

winding

resistance

required

Control box

type

order

No.

rJ ref.

#

hp kw Volts Sf

amps watts amps watts

main

(b-y)

Start

(r-y)

3-

Wire

with

Q.D.

Cap.

Start

Box

M05411 50C301 0.5 0.37 115

1.6

Y – 11.0

B – 11.0

R – 0

733

Y – 12.6

B – 12.6

R – 0

1021

49.6

0.9 -

1.6

5.7 -

7.0

CB05411

M05412 50C311 0.5 0.37

230

1.6

Y – 5.5

B – 5.5

R – 0

745

Y – 6.3

B – 6.3

R – 0

1033

22.3

4.2 -

4.9

17.4 -

18.7

CB05412

M07412 75C311 0.75 0.55

1.5

Y – 7.2

B – 7.2

R – 0

1014

Y – 8.3

B – 8.3

R – 0

1381

32.0

2.6 -

3.6

11.8 -

13.0

CB07412

M10412 100C311 1.0 0.75

1.4

Y – 8.4

B – 8.4

R – 0

1267

Y – 9.7

B – 9.7

R – 0

1672

41.2

2.2 -

3.2

11.3 -

12.3

CB10412

3-

Wire

with

CSCR

(CR)

or

Mag-

netic

Con-

tactor

(MC)

Con-

trol

Box

M05412 50C311 0.5 0.37

1.6

Y – 4.1

B – 4.1

R – 2.2

720

Y – 4.9

B – 4.4

R – 2.1

955

22.3

4.2 -

4.9

17.4 -

18.7

CB05412CR

M07412 75C311 0.75 0.55

1.5

Y – 5.1

B – 5.0

R – 3.2

1000

Y – 6.3

B – 5.6

R – 3.1

1300

32.0

2.6 -

3.6

11.8 -

13.0

CB07412CR

M10412 100C311 1.0 0.75

1.4

Y – 6.1

B – 5.7

R – 3.3

1205

Y – 7.2

B – 6.3

R – 3.3

1530

41.2

2.2 -

3.2

11.3 -

12.3

CB10412CR

M15412 150C311 1.5

1.1

1.3

Y – 9.7

B – 9.5

R – 1.4

1693

Y – 11.1

B – 11.0

R – 1.3

2187

47.8

1.6 -

2.3

7.9 -

8.7

CB15412CR or

CB15412MC

M20412 200C311 2.0

1.5

1.25

Y – 9.9

B – 9.1

R – 2.6

2170

Y – 12.2

B – 11.7

R – 2.6

2660

49.4

1.6 -

2.2

10.8 -

12.0

CB20412CR or

CB20412MC

M30412 300C311 3.0

2.2

1.15

Y – 14.3

B – 12.0

R – 5.7

3170

Y – 16.5

B – 13.9

R – 5.6

3620

76.4

1.1 -

1.4

2.0 -

2.5

CB30412CR or

CB30412MC

M50412 500C311 5.0

3.7

1.15

Y – 24.0

B – 19.1

R – 10.2

5300

Y – 27.0

B – 22.0

R – 10.0

6030

101.0

0.62 -

0.76

1.36 -

1.66

CB50412CR or

CB50412MC

GENEratIoN I - 3-wIrE, SINGlE phaSE motor wIrE SIzING Chart

Centripro motor lead lengths - 3-wire motors, 1Ø, 4" motors

Based on Service Factor Amps, 30º C Ambient and 5% Voltage Drop

motor rating

60º C and 75º C Insulation - awG Copper wire Size

hp Volts kw fla Sfa

14

12

10

8

6

4

3

2

1

1/0

2/0

3/0

4/0

0.5

115

0.37

11

12.6

87

138

221

349

544

867

1090

1376

1734

2188

2761

3485

4391

0.5

230

0.37

5.5

6.3

348

553

883

1398

2175

3467

4359

5505

6935

8753 11044 13942 17564

0.75

0.55

7.2

8.3

264

420

670

1061

1651

2632

3309

4178

5264

6644

8383 10582 13332

1.0

0.75

8.4

9.7

226

359

573

908

1413

2252

2831

3575

4504

5685

7173

9055 11408

1.5

1.1

9.7

11.1

197

314

501

793

1234

1968

2474

3124

3936

4968

6268

7913

9969

2.0

1.5

9.9

12.2

180

286

456

722

1123

1790

2251

2843

3581

4520

5703

7199

9070

3.0

2.2

14.3 16.5

133

211

337

534

830

1324

1664

2102

2648

3342

4217

5323

6706

5.0

3.7

24

27

206

326

507

809

1017

1284

1618

2042

2577

3253

Tables based on values from NEC, Tables 310.16 and 310.17 and NEC, Chapter 9, Table 8 Conductor Properties.

NOTE: Motors and control boxes are designed to operate on 230V systems. Systems with low line voltage, between 200 – 207 volts require

the next larger cable size than shown in the 230V charts. If using a 3-wire motor with control box on a low voltage application switch

to a 208V start relay. The 208V start relay order numbers are found on control box repair part charts in this manual.

Temperature Conversions: 20º C = 68º F, 30º C = 86º F, 60º C = 140º F, 75º C = 167º F, 90º C = 194º F