Centripro, Residential water systems, Aquavar solo data – Xylem BMAID R4 User Manual

Page 28

PAGE 28

Residential Water Systems

CentriPro

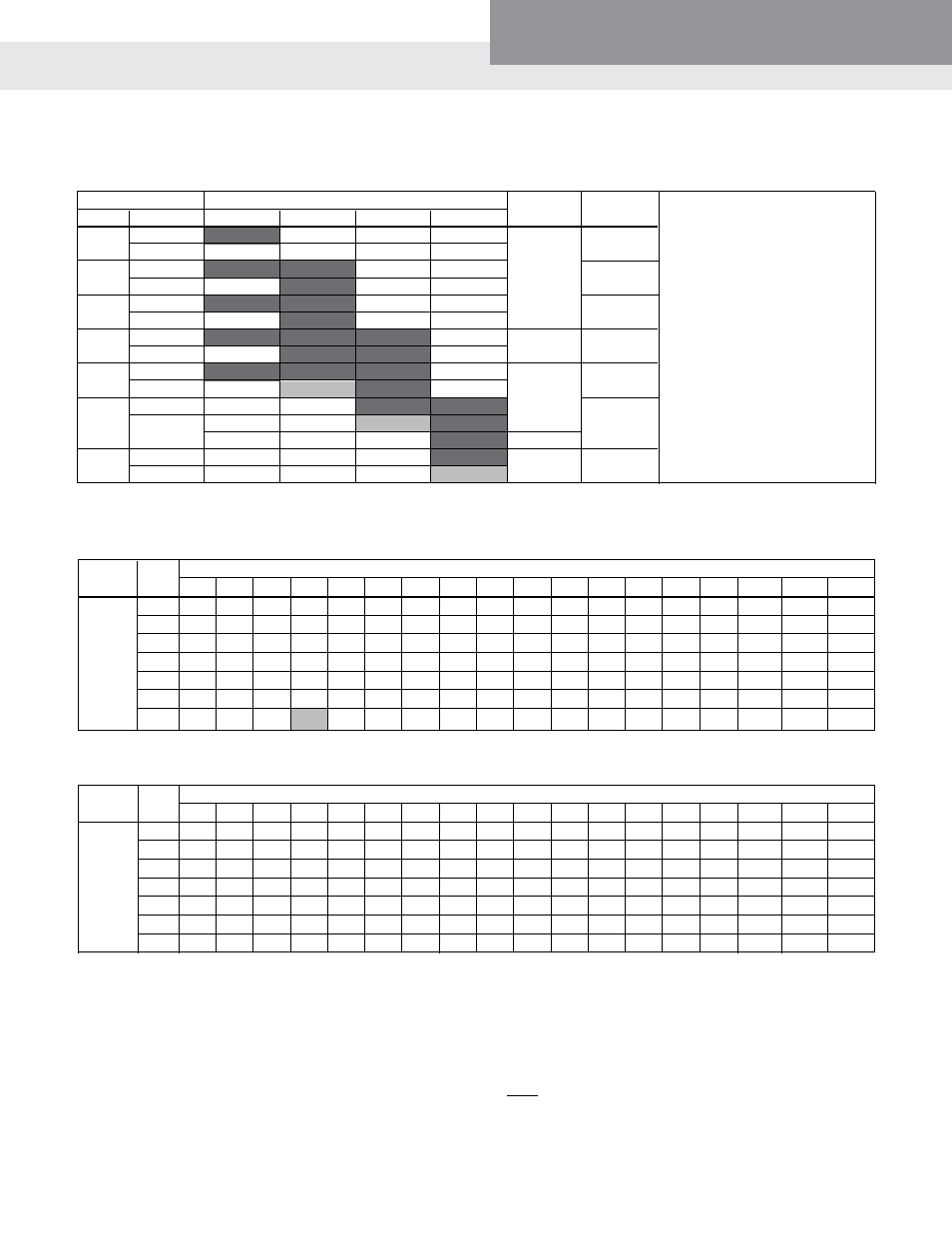

aquaVar Solo Data

Service Entrance to Controller

Controller motor

Copper wire Size 75ºC Insulation Exposed to a maximum of 50ºC (122ºf) ambient temperature ⑥

Input

hp 14 12 10 8 6 4 3 2 1 1/0 2/0 3/0 4/0 250 300 350 400 500

½ 366 583 925 1336 2107 3345 4175 5267 6637 8364

¾ 279 445 706 1020 1608 2552 3186 4019 5065 6383 8055

1

226 360 571 824 1300 2064 2576 3250 4095 5161 6513 8201

1½ * 286 455 657 1036 1644 2052 2589 3262 4111 5188 6533 8236 9710

2

*

* 331 478 754 1197 1495 1886 2376 2995 3779 4759 5999 7073 8455 9852

3 * * 246 355 561 890 1111 1401 1766 2225 2808 3536 4458 5256 6283 7321 8343

5 * * *

218 343 545 680 858 1081 1363 1720 2165 2730 3219 3847 4483 5109 6348

230V

1 PH

Controller to motor

Controller motor

Copper wire Size 75ºC Insulation Exposed to a maximum of 50ºC (122ºf) ambient temperature ⑥

output

hp 14

12

10 8 6 4 3 2 1 1/0

2/0

3/0

4/0

250

300

350 400 500

½ 905 1442 2290 3306 5213 8276

¾ 690 1100 1748 2523 3978 6316 7884 9945

1

558 890 1413 2040 3216 5106 6375 8041

1½ 445 709 1126 1625 2562 4068 5078 6406 8072

2

324 516 820 1184 1866 2963 3699 4666 5879 7410 9351

3

241 384 609 880 1387 2202 2749 3467 4369 5506 6949 8750

5

* 235 373 539 849 1348 1683 2123 2675 3372 4255 5358 6755 7964 9520

⑤

Reduce lengths by 13% for 200 V systems.

⑥

Lengths in bold require 90ºC wire. Shading indicates 40º C maximum ambient.

* Wire does not meet the N.E.C. ampacity requirement.

230V

3 PH

The lengths in each of the Wire Sizing tables represent 100% of the allowable voltage drop when motor is running at full load.

When sizing wire, the voltage drop of each wire segment must be included. The total must not exceed 100% of the allow-

able drop. Take for example a 1.5 HP motor with a distance from Service Entrance to Controller of 100' and 500' between the

Controller and Motor.

• Service Entrance to Controller = 100' of 10 AWG (100/455) = 22 % (455' is from the S.E. to Controller chart)

• Controller to Motor

= 500' of 12 AWG (500/709) = 71 % (709' is from the Controller to Motor chart)

Total Drop (must be ≤ 100%) 93 %

If the distance from the Controller to Motor was 600' (600/709) = 85% + 22% = 107%, we would need to use #10 wire for that

segment, ex. 600/1126 = 53% + 22% (for 100' of #10) = 75% which is acceptable. It is also acceptable to use different wire

sizes for the Buried and Well sections of wire.

WiRE Sizing – MAxiMuM CABlE lEngthS in FEEt to liMit VoltAgE DRoP to 5% FoR 230 V SyStEMS ⑤

CoNtrollEr, brEakEr, GENErator SIzING

motor

Controller model ➁ Circuit Generator

➃

hp Voltage

➀

1aS15 3aS20 3aS30 3aS50 breaker ➂ (Va)

½

230

2200

200

¾

230

15

2900

200

1

230

3500

200

1½

230

20

4400

200

2

230

6100

200

30

230

3

200

8100

40

5

230

50

13300

200

➀

Supply voltage must be 196 VAC – 265

VAC.

➁

Shaded areas indicate which controller

models can be used with which motors.

Lighter shading indicates combina-

tions where controller will limit peak

performance to 85% of catalog value for

pump/motor.

➂

Circuit Breaker or Dual Element Time Delay

Fuse Size (Amps) protecting branch circuit

supplying controller.

➃

Minimum size of single phase 240 V

generator required.