Centripro, Residential water systems – Xylem BMAID R4 User Manual

Page 4

PAGE 4

Residential Water Systems

CentriPro

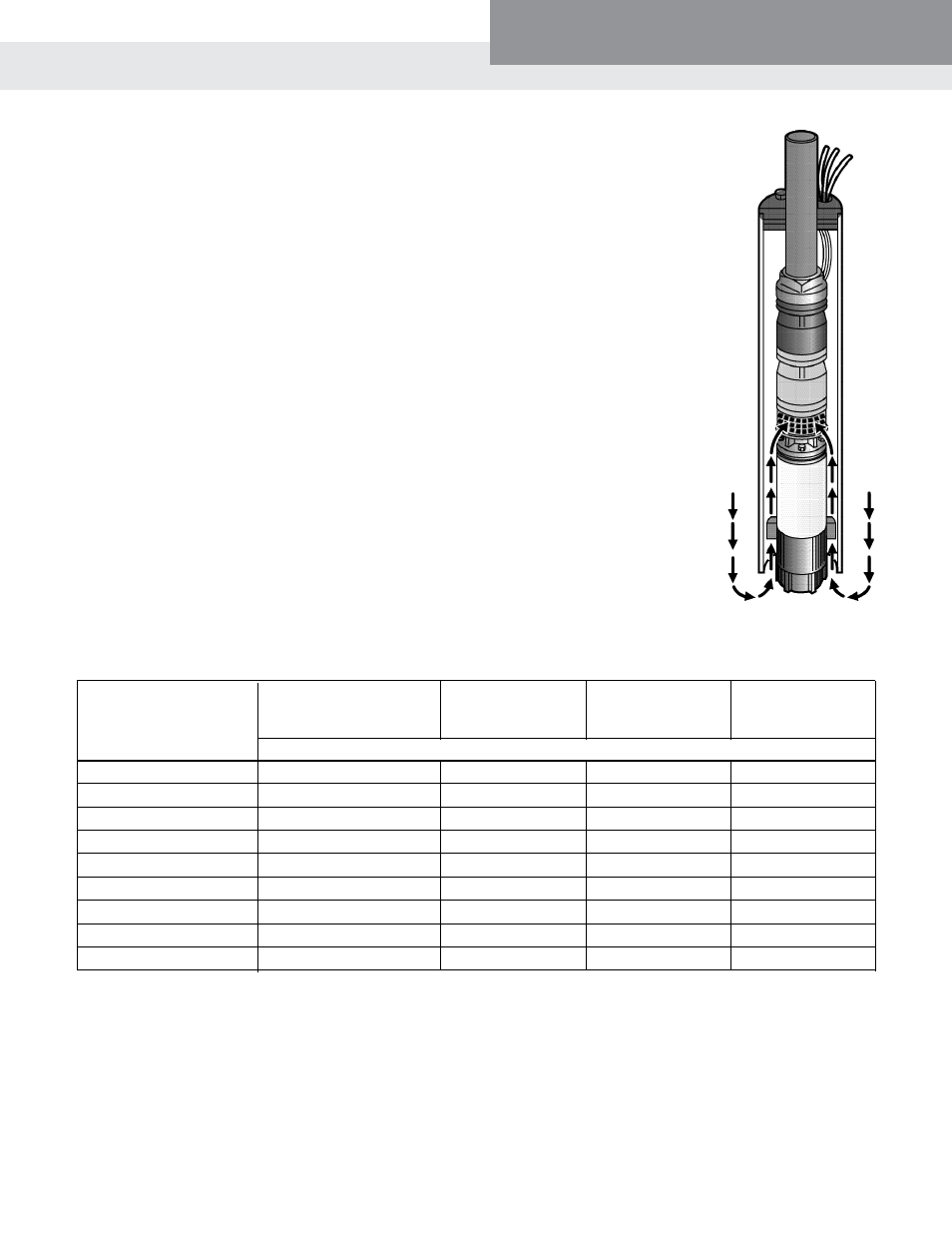

motor CoolING, tEmpEraturE aND tImE ratINGS

All 4 inch CentriPro motors may be operated continuously in water up to 86º F. Optimum

service life will be attained by maintaining a minimum flow rate past the motor of .25 feet

per second. Use a Flow Sleeve if velocity is below the .25’/sec, if the well is top feeding or

when the pump is used in a large body of water or large tank.

Six (6) inch canned design motors from 5 – 40 HP will operate in water up to 95º F (35º

C), without any de-rating of horsepower, with a minimum flow rate of .5 ft./sec. past the

motor. 6" – 50 HP and all 8" – 10" motors can operate in 77º F (25º C) water with .5'/sec

velocity past the motor.

One way to make a flow sleeve is to install a well seal above the pump discharge and

slip a piece of casing over the pump and affix it to the well seal. Drill three holes at 120º

intervals on the lower section of the casing and insert (3) screws and nuts through the

casing, just touching the motor. Tighten the nuts out against the casing. Insure that the

screws do not protrude out too far as you don’t want them catching on well joints.

pump CoolING aND lubrICatIoN

In addition to motor cooling, another reason to maintain minimum flow rates is pump

lubrication. All manufacturers’, either on curves or in selection charts, show minimum

flows. This insures that rotating pump parts are properly lubricated to prolong service

life and reduce friction. A dead headed pump will super heat water very quickly, and hot

water has no lubricity.

mINImum flow ratES for propEr motor CoolING

3.75" Diameter

Cp = 5.5" Dia.

fE = 5.38" Dia.

Cp = 7.52" Dia.

well or Sleeve

4" Cp or fE motor

6" Cp motor

6" fE motor

8" Cp motor

Diameter (inches)

.25'/sec

.5'/sec.

.5'/sec.

.5'/sec.

Gpm required

4

1.2

–

–

–

5

7

–

–

–

6

13

7

9

–

7

20

23

25

–

8

30

41

45

9

10

50

85

90

53

12

80

139

140

107

14

110

198

200

170

16

150

276

280

313

Multiply gpm by .2271 for m

3

/Hr.

Multiply gpm by 3.785 for l/min.

FLOW SLEEVE