Application information – Diodes AP65550 User Manual

Page 11

AP65550

Document number: DS36336 Rev. 2 - 2

11 of 14

www.diodes.com

April 2014

© Diodes Incorporated

AP65550

Application Information

(cont.)

Inductor

Calculating the inductor value is a critical factor in designing a buck converter. For most designs, the following equation can be used to calculate

the inductor value;

SW

L

IN

OUT

IN

OUT

f

ΔI

V

)

V

(V

V

L

Where

L

ΔI

is the inductor ripple current.

And

SW

f

is the buck converter switching frequency.

Choose the inductor ripple current to be 30% of the maximum load current. The maximum inductor peak current is calculated from:

2

ΔI

I

I

L

LOAD

L(MAX)

Peak current determines the required saturation current rating, which influences the size of the inductor. Saturating the inductor decreases the

converter efficiency while increasing the temperatures of the inductor and the internal MOSFETs. Hence choosing an inductor with appropriate

saturation current rating is important.

A 1µH to 3.3µH inductor with a DC current rating of at least 25% percent higher than the maximum load current is recommended for most

applications. For highest efficiency, the inductor’s DC resistance should be less than 100mΩ. Use a larger inductance for improved efficiency

under light load conditions.

The phase boost can be achieved by adding a additional feed forward capacitor (C4) in parallel with R1.

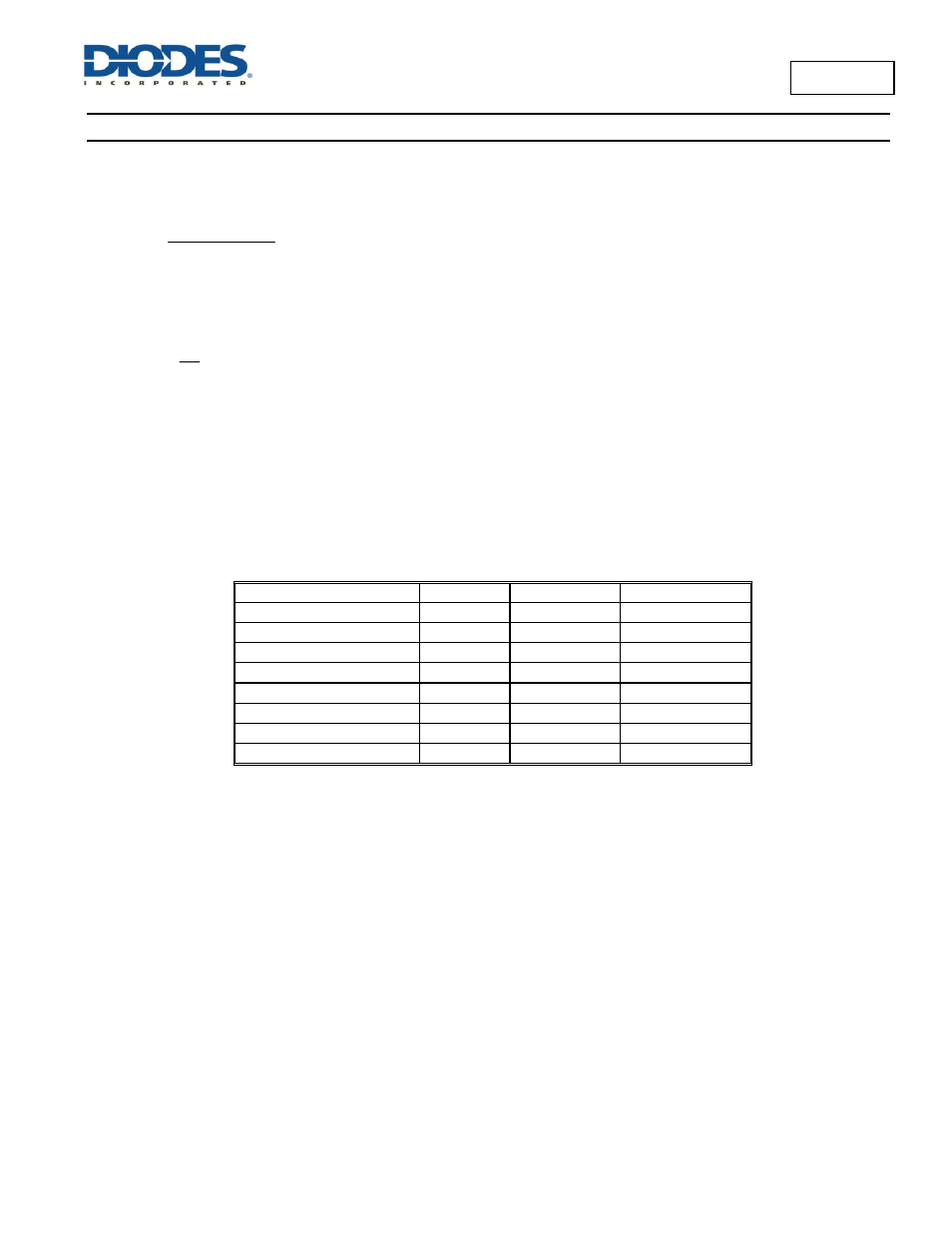

Output Voltage (V)

C10(pF)

L1(µH)

C5+C9(µF)

1

—

1.0-1.5

22-68

1.05

—

1.0-1.5

22-68

1.2

—

1.0-1.5

22-68

1.5

—

1.5

22-68

1.8

5-22

1.5

22-68

2.5

5-22

2.2

22-68

3.3

5-22

2.2

22-68

5

5-22

3.3

22-68

Table 2. Recommended Component Selection

Input Capacitor

The input capacitor reduces the surge current drawn from the input supply and the switching noise from the device. The input capacitor has to

sustain the ripple current produced during the on time on the upper MOSFET. It must hence have a low ESR to minimize the losses.

The RMS current rating of the input capacitor is a critical parameter that must be higher than the RMS input current. As a rule of thumb, select an

input capacitor which has RMs rating that is greater than half of the maximum load current.

Due to large dI/dt through the input capacitors, electrolytic or ceramics should be used. If a tantalum must be used, it must be surge protected.

Otherwise, capacitor failure could occur. For most applications, greater than 10µF ceramic capacitor is sufficient.

Output Capacitor

The output capacitor keeps the output voltage ripple small, ensures feedback loop stability and reduces the overshoot of the output voltage. The

output capacitor is a basic component for the fast response of the power supply. In fact, during load transient, for the first few microseconds it

supplies the current to the load. The converter recognizes the load transient and sets the duty cycle to maximum, but the current slope is limited

by the inductor value.