Sstw00, 3a0a ba, Arracuda – GE Industrial Solutions SSTW003A0A Barracuda Series User Manual

Page 9: A™ series, S; dc-dc, C conver, Rter powe, Er modu, Data sh, Heet

G

S

3

c

a

3

C

P

P

d

d

E

F

c

F

F

F

p

L

T

u

c

m

c

m

p

GE

SSTW00

36-75Vdc In

March 26, 2013

current that ca

ambient tempe

3m/s (600 ft./m

Curves section.

Please refer to t

Process For Op

detailed discuss

device tempera

EMC Requir

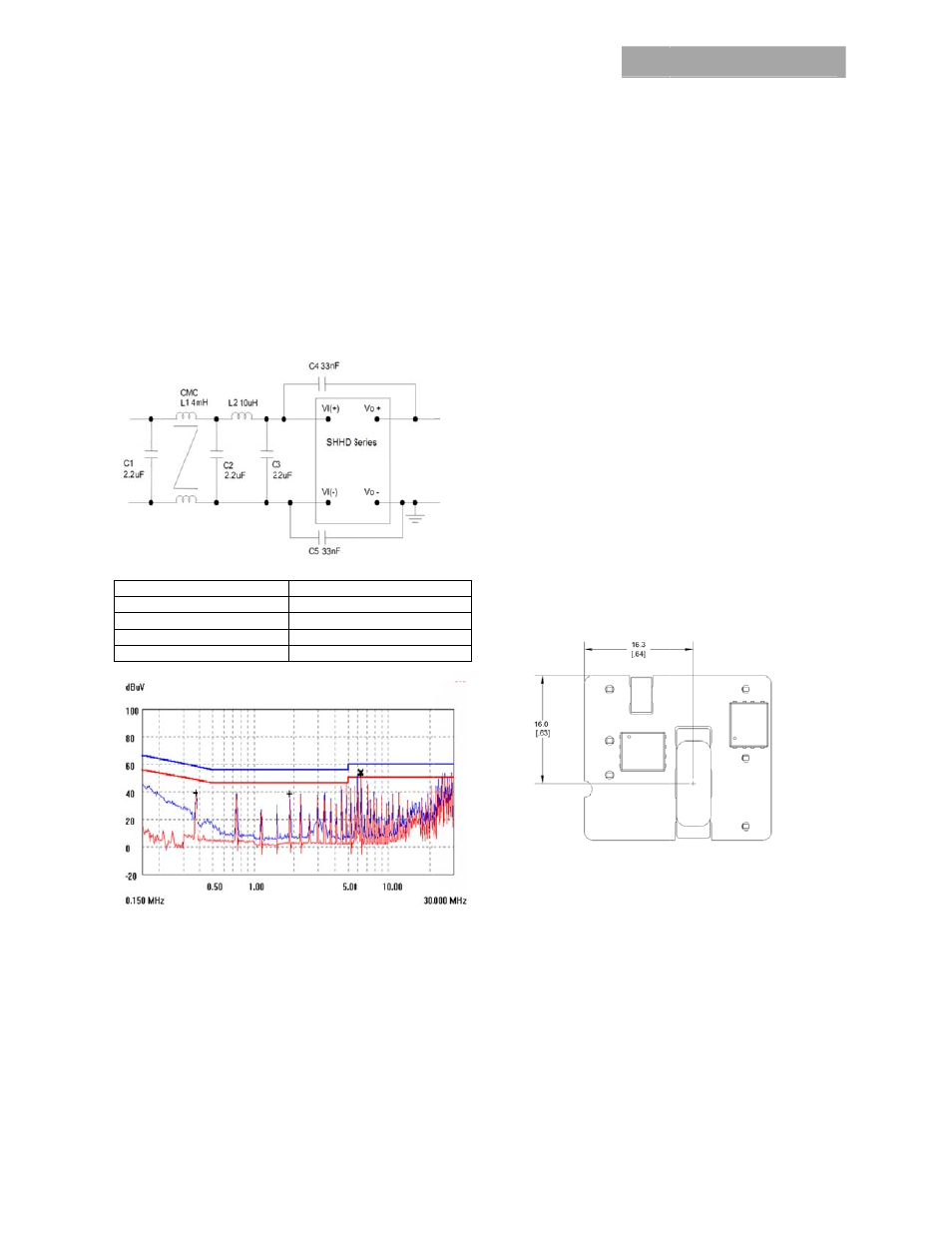

Figure 16 show

conducted emis

Ref

C1 , C

C4

L

L

Figure 16. Sugg

Figure 17. EMC

For further info

please refer to t

Layout Con

The SSTW powe

used in fine pitc

component clea

module and the

copper areas o

module. Also a

power module.

3A0A Ba

nput; 5.0Vd

n be delivered

erature (T

A

) for n

min) are shown

the Application

en-Frame Boa

sion of therma

atures.

rements

ws a maximum

ssion limits of E

f Des

C2, C3

4, C5

L1

L2

gested Configu

C signature usi

rmation on des

the FLTR100V1

nsideration

er module serie

ch system card

arance betwee

e mounting bo

n the outer lay

void placing vi

arracuda

dc, 3A, 15W

©

by each modu

natural convec

in the respectiv

n Note “Therma

rd-Mounted Po

al aspects inclu

filter configura

EN55022 Class

2

3

4m

10

uration for EN

ing above filte

signing for EMC

10 data sheet (

ns

es are low prof

d architectures

en the bottom

ard is limited. A

yer directly und

a interconnect

a™ Series

W Output

©2012 General E

ule versus local

ction and up to

ve Characteris

al Characteriza

ower Modules”

ding maximum

ation to meet th

s B.

Filter

.2uF/100V

33nF Y cap

mH CM choke

uH inductor

55022 Class B

er.

C compliance,

FDS01-043EPS

file in order to b

s. As such,

of the power

Avoid placing

derneath the po

ts underneath

s; DC-DC

lectric Company

l

o

tics

ation

” for a

m

he

B.

S).

be

ower

the

For a

shee

The S

Thro

Thr

The

SAC

com

singl

RoHS

free

3C/

that

210

260

Hole

solde

proc

cons

Sur

Pick

The S

open

asse

The S

mag

Note

Figu

Z Pla

The ‘

nom

Noz

The

fram

whe

Varia

plac

proc

The

oper

C Conver

y. All rights reserv

additional layo

et.

SSTW family of

ough-Hole (TH)

ough-Hole S

RoHS-complia

(Sn/Ag/Cu) Pb-

ponents. They

le or dual wave

S-compliant fin

wave soldering

/s is suggested

the temperatu

C. For Pb sold

C, while the Pb

e module is also

ering. Refer to

cess details. If a

sult with your G

rface Moun

k and Place

SSTW-SR serie

n-frame constr

embly within a

SSTW-SR serie

gnetic compone

e: All dimension

re 18. Pick and

ane Height

‘Z’ plane heigh

minal with an RS

zzle Recomme

module weight

me construction

n compared w

ables such as n

ement speed s

cess.

minimum reco

ration is 5mm.

rter Powe

ved.

ut guide-lines,

f power modul

or Surface Mo

Soldering In

nt (Z codes) thr

-free solder an

y are designed

e soldering ma

nish that is com

g processes. A

. The wave pre

ure of the powe

er, the recomm

b-free solder po

o compatible w

the Reflow Sol

additional info

GE representat

nt Informat

s of DC-to-DC

ruction and are

fully automate

s modules are

ent surface to

ns in mm [in].

d Place Locatio

t of the pick an

SS tolerance of

endations

t has been kep

n. Even so, they

with convention

nozzle size, tip

should be cons

ommended noz

The maximum

Data Sh

er Modu

refer to the FL

es is available

unt (SMT) solde

nformation

rough-hole pro

d RoHS-compl

to be processe

achines. The pi

mpatible with b

maximum pre

eheat process

er module boa

mended pot tem

ot is 270C ma

with paste-in-h

dering Informa

rmation is nee

ive for more de

tion

power convert

e designed for

ed manufacturi

designed to us

allow for pick a

on.

nd place locatio

f +/-0.25 mm.

pt to a minimum

y have a relativ

nal SMT compo

style, vacuum

sidered to optim

zzle diameter fo

m nozzle outer d

heet

les

Page

LTR100V10 dat

for either

ering.

oducts use the

iant

ed through

ns have an

both Pb and Pb

eheat rate of

should be such

rd is kept below

mperature is

ax. The Throug

ole reflow

ation section fo

ded, please

etails.

ters use an

surface mount

ing process.

se the main

and place.

on is 7.50mm

m by using ope

vely large mas

nents.

pressure and

mize this

or reliable

diameter, whic

e 9

a

b-

h

w

h

or

t

en

ss

h