Product description, Step 1 – unpack and inspect, Step 2 – installation – GE Industrial Solutions Record Plus TDR, NEMA 1, 12: FC100 User Manual

Page 2: Step 3, Handle operation

Product Description

These instructions describe the installation

procedure for the integral handle operator accessory,

type TDR, on

Record Plus™

FC100 circuit breakers,

as illustrated in Figure 1. The type TDR handle is

designed for direct mounting to the breaker in either

vertical (cat. no. FCNRC, FCNRCN and FCNRCNI)

or horizontal orientation (cat. no. FCNRD and

FCNRDN). A door ring on the handle operator

projects through a hole in the front of the enclosure

door. These handles are suitable for use with NEMA

1, NEMA 12, or NEMA 12K enclosures.

An interlock kit (cat. no. FCFRDRCK) for adapting

the enclosure door and the door ring gasket (cat. no.

SEFRGSK) are available separately.

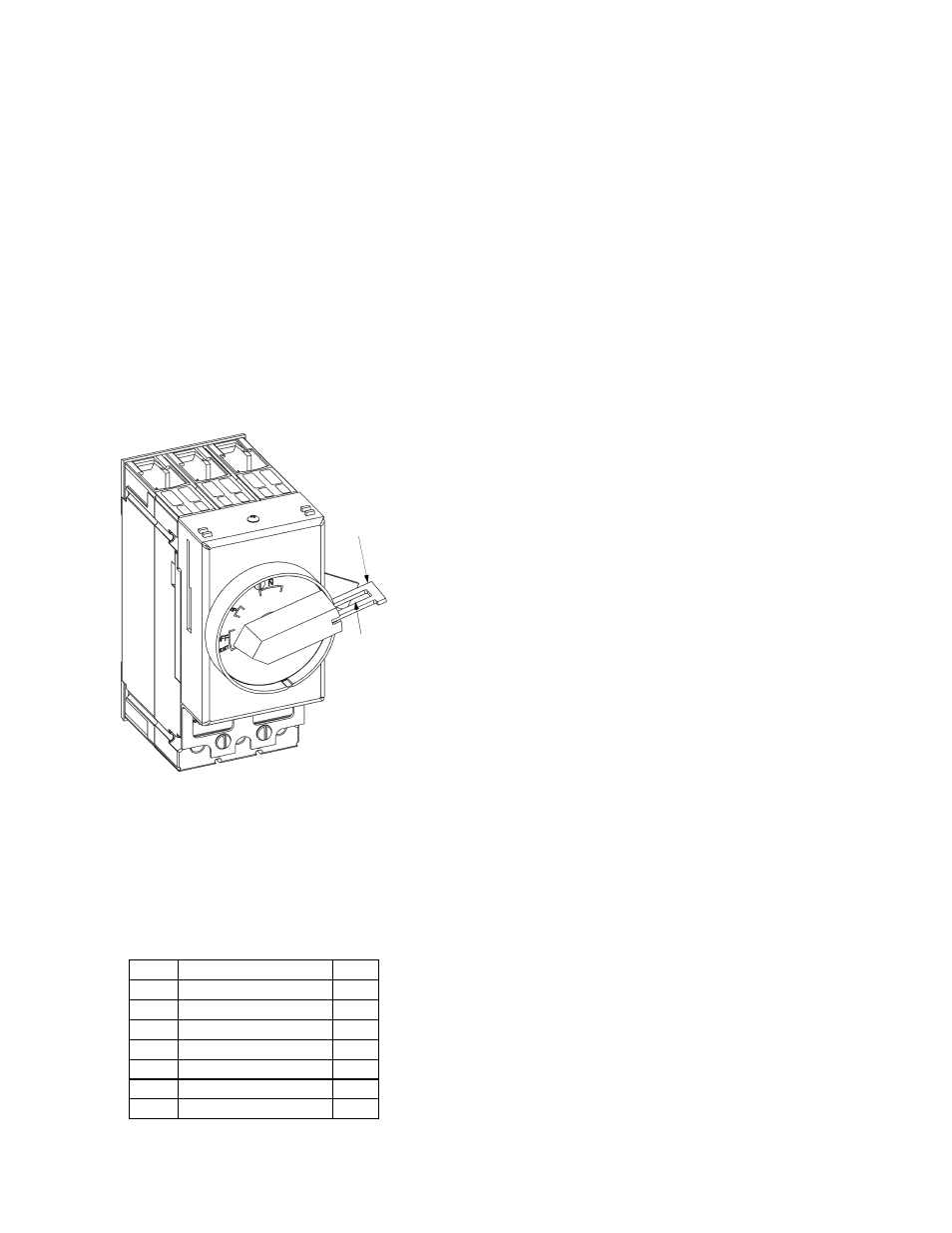

Figure 2. Locking the circuit breaker OFF.

Step 1 – Unpack and Inspect

Unpack the integral handle operator kit and inspect

the parts for any shipping damage. Verify that all

parts are supplied, as listed in Table 1.

Note that the numbers in brackets in the following

figures and installation instructions refer to the item

numbers in Table 1.

Item Description

Qty.

1 Operator

assembly 1

2

Screw, #8-32 x 2.81"

4

3 L

bracket

1

4 Lock

washer

4

5 Screw,

#8-32

x

5

/

16

4

6 Grounding

cable

1

7 SEMS

screw

1

Table 1. Parts supplied in the type TDR integral handle operator kit.

Step 2 – Installation

Use the following procedure to install the handle

operator kit to the circuit breaker. Outline drawings

showing the dimensions of the installed operator are

found in fig 8, fig 9 and fig 10.

1.

Push the trip button to place the breaker

operating handle in the TRIP position, as

2.

Mount the breaker to the enclosure with the

four #8-32 x 2.81" screws [2], as shown in Figure

3. Tighten the screws to 16 - 20 in-lb.

3.

Attach the L bracket [3] to the breaker with two

#8-32 x 5/16" screws [5] and lock washers [4], as

shown in Figure . Tighten the screws to 16 - 20

in-lb.

4.

Turn the rotary handle in the handle operator

assembly [1] to the TRIP position. Mount the

operator assembly to the breaker with a

grounding cable [6], two #8-32 x 5/16" screws

[5] and lock washers [4], as shown in fig5. The

top of the assembly must rest on the L bracket

[3]. Tighten the screws to 9 -11in-lb.

Handle

Locking Hasp

5.

Secure the handle operator assembly [1] to the

L bracket [3] with the SEMS screw [7], as shown

in Figure 6.

Use the identical procedure to install the horizontal-

mount rotary handle, as shown in Figure 7

.

Padlock

Slot

Step 3

-

Handle Operation

The mechanism operates with a rotary motion from

the OFF/RESET position to ON.

In FCNRC/D, FCNRCN /DN, when the breaker is

ON, the interlock arm prevents the enclosure door

from opening. If it is necessary to open the door

with the breaker ON, turn the interlock defeat screw

clockwise to disengage the interlock arm.

To lock the handle in the RESET position, pull the

hasp out of the end of the handle and through the

slot in the door ring, as shown in Figure 2. Attach a

padlock through the slot in the hasp to prevent the

handle from rotating. The locking hasp accepts up

to three padlocks with 1/4-inch shanks.