Panels with full-height door fronts, After installing the interior, Attention – procedure for aluminum terminations – GE Industrial Solutions Spectra Series Power Panelboards APN and APNB User Manual

Page 2

Panels with Full-Height Door Fronts

6. If a full-height door front is to be used on the panel, it is

necessary to reinstall the deadfront once the wiring has

been brought into the panel. (These instructions are also

provided with the door front.)

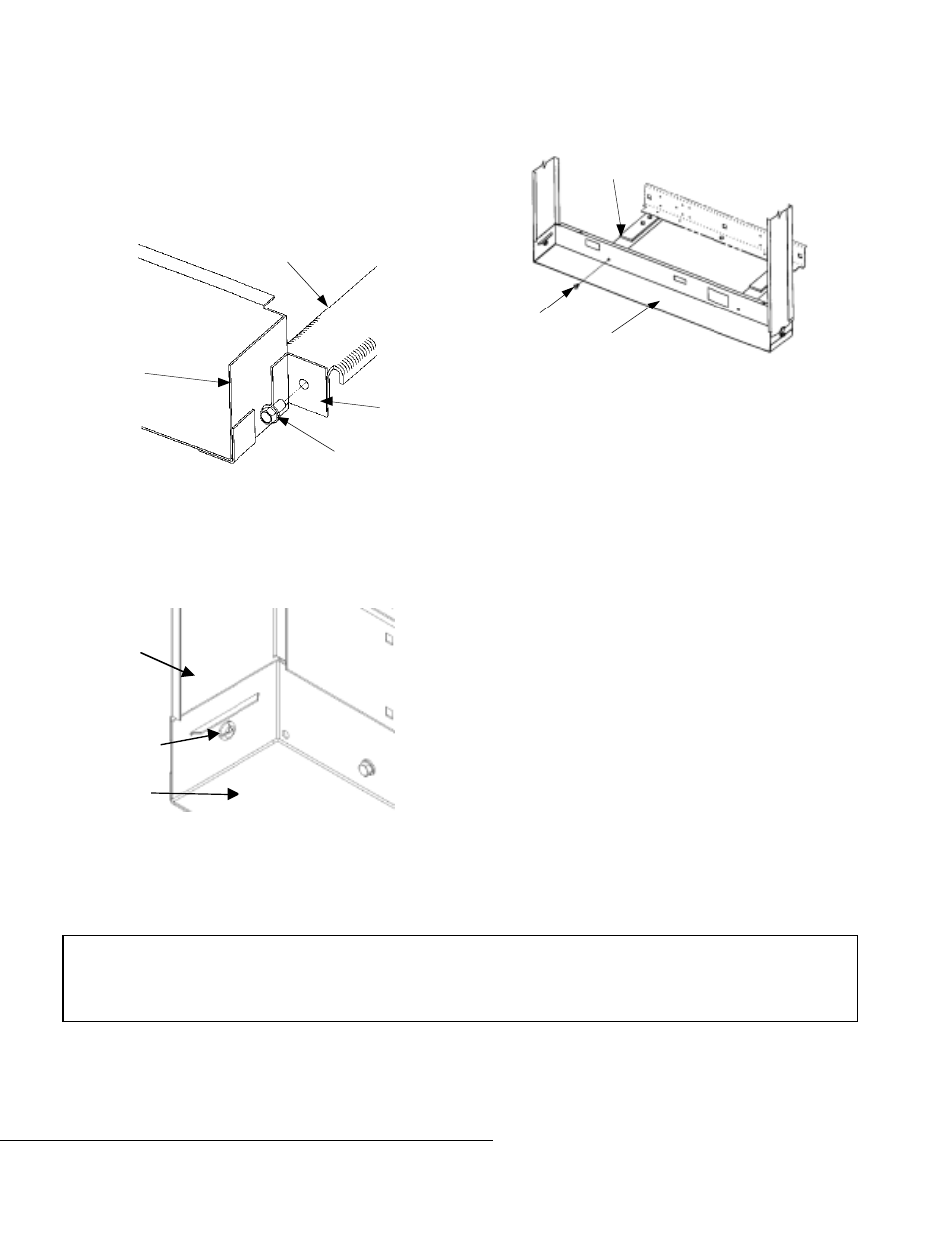

27- and 31-inch-wide panels. To replace or install the

deadfront, first install the top and bottom ends to the

mounting post, as shown in Figure 5. Tighten the

1

/

4

-20

hex-head screws to 50–60 in-lb.

Figure 5. Installing the ends to the mounting post.

27–44-inch-wide panels. Fasten the end filler plates to the

side plates with the

1

/

4

-turn fasteners shown in Figure 6.

The end filler plate with labeling attached must be placed

at the load end of the panel, opposite to the incoming

power.

Figure 6. Fastening the end filler to the side plate.

36–44-inch-wide panels. Refasten the end fillers to the

mounting posts, tightening the

1

/

4

-20 screws to 50–60 in-lb,

as shown in Figure 7. The end filler plate with labeling

attached must be placed at the load end of the panel,

opposite to the incoming power.

Figure 7. Fastening the end fillers to the mounting posts.

After Installing the Interior

Do not discard the remaining contents of the bag that contained

these instructions. The circuit identification tabs should be

used, as applicable, at the time the circuit protective devices are

installed. The NEMA instruction sheet provided should be

retained for use by maintenance personnel.

If plug-in devices are used, the area above the device-mounting

latches should be kept clear of any wires running through the

side gutters. This facilitates the future removal of a device, if

necessary.

Attention – Procedure for Aluminum

Terminations

1. Strip the insulation, being careful to not nick the wire.

2. Clean the wire strands with a wire brush.

3. Thoroughly coat the stripped conductor with a suitable

antioxidant compound, such as ALNOX or PENETROX

A13.

4. Insert the conductor and tighten the connector screw to the

required torque, as indicated on the rating label.

g

GE Industrial Systems

General Electric Company

41 Woodford Ave., Plainville, CT 06062

GEH5589 R07 0501

© 2001 General Electric Company

These instructions do not cover all details or variations in equipment nor do they provide for every possible contingency that

may be met in connection with installation, operation, or maintenance. Should further information be desired or should

particular problems arise that are not covered sufficiently for the purchaser’s purposes, the matter should be referred to the

GE Company.

End

Filler

Mounting

Post

Welded

Bracket

1

/

4

-20

Screw

Side

Plate

End

Filler

1

/

4

-Turn

Fastener

Mounting

Post

End

Filler

1

/

4

-20

Screw