3B Scientific Steam Engine G User Manual

Page 6

6

(Fig. 1, c). The steam flows out via the exhaust steam

hose

2

and the exhaust steam pipe

br

. The condensed

water that accumulates drips out via the condensation

hose

1

into the condensation beaker

bu

.

When the piston has reached the dead point at the top,

both of the steam ducts are closed again. The flywheel

drags the engine past this top slack point, after which

steam is once again fed in and the procedure repeats

from the start (Fig. 1, d).

4. Operation

•

Open the boiler cap

bp

and fill up the boiler with

distilled water (demineralised water conforming to

VDE 0510). Do not fill up the boiler to the brim, main-

tain an air column of approx. 5 mm. The steam en-

gine functions equally well even if the boiler is only

half-filled. Only the operating duration is correspond-

ingly reduced.

•

Light the wick of the spirit burner and heat the boiler.

•

Shut the steam inlet opening to enable quicker build

up of pressure.

•

After approx. 2 minutes, the water in the boiler be-

gins to boil. From this point onwards, only approx.

2-3 minutes are needed to attain the required oper-

ating pressure. Steam flows via the steam feeding

hose into the steam inlet opening. Excess condensed

water drips into the condensate beaker via the drain-

age hose

3

. For this purpose, channels that facili-

tate collection and transfer of the condensed water

are milled into the frame.

•

The engine can now be operated by turning the fly-

wheel in a clockwise direction (while observing the

main cylinder).

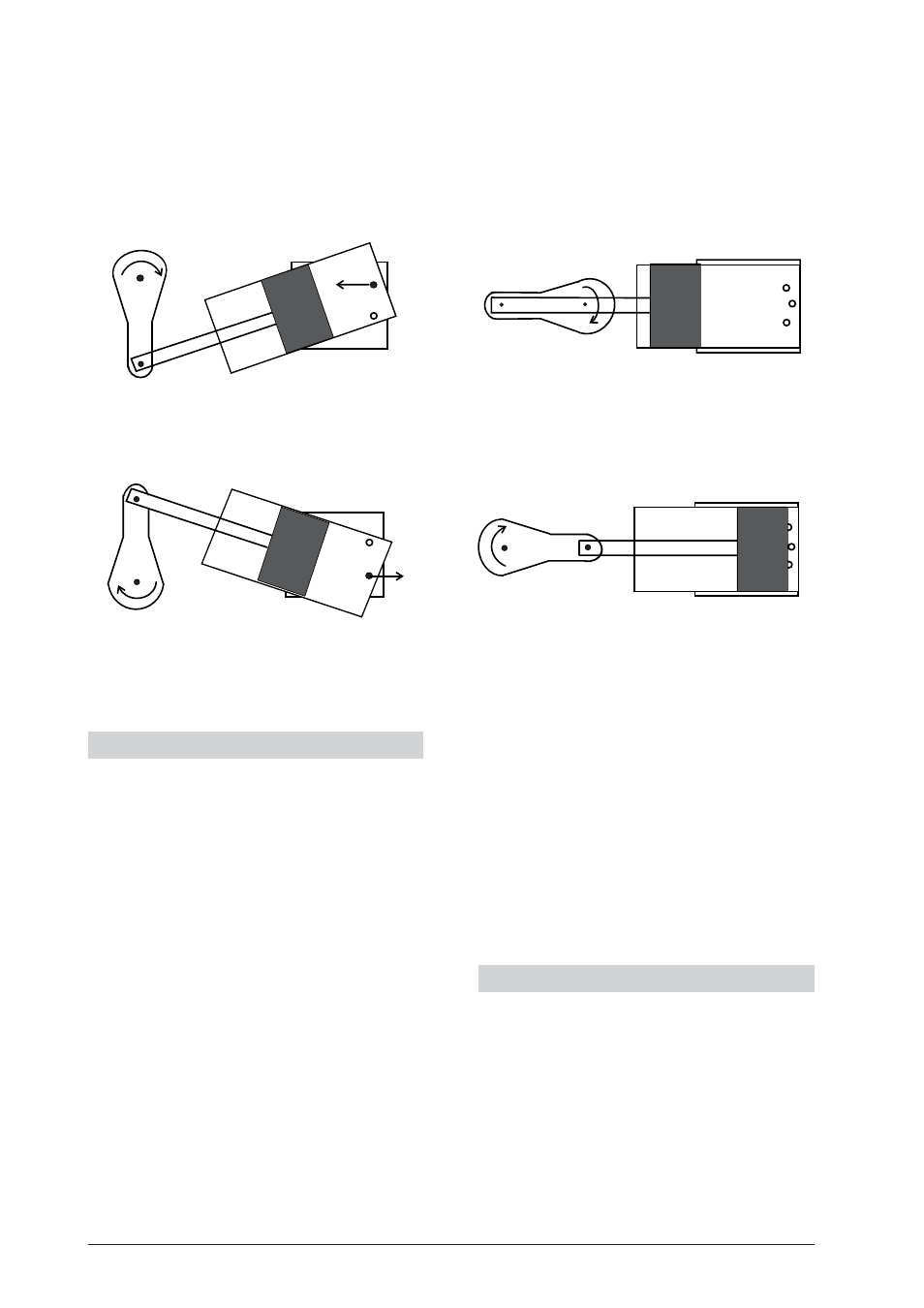

Fig. 1: Work cycle of an oscillating steam engine

•

The power of the engine decreases if there is not

enough water left in the boiler. It is not permitted to

heat the boiler if it is not filled with water. The spirit

burner should, therefore, be extinguished at the ap-

propriate time.

•

Do not blow out the flame in the proximity of the

boiler. Use the attached cap to extinguish the flame.

•

During the cooling process, condensed water is sucked

up from the condensation beaker via the condensa-

tion hose, frame and steam feeding hose and trans-

ferred into the boiler.

5. Storage and maintenance

•

Store the steam engine in a dust-free place.

•

To clean use a damp cloth, if necessary, with some

washing-up liquid. Never use solvents or aggressive

cleaning agents to clean the acrylic glass components.

•

Frequent use of the apparatus may cause a layer of

soot to deposit on the underside of the boiler

bq

due

to the constant play of a flame. This, however, can be

dissolved and removed by using a cloth soaked in

acetone.

•

In order to prevent water stains appearing, dry thor-

oughly after cleaning.

a

b

d

c

3B Scientific GmbH • Rudorffweg 8 • 21031 Hamburg • Germany • www.3bscientific.com • Technical amendments are possible