Derale Performance GM Thermostatic Sandwich Adapter Kit with 1_2" NPT Ports User Manual

Diagram #2, Diagram #1

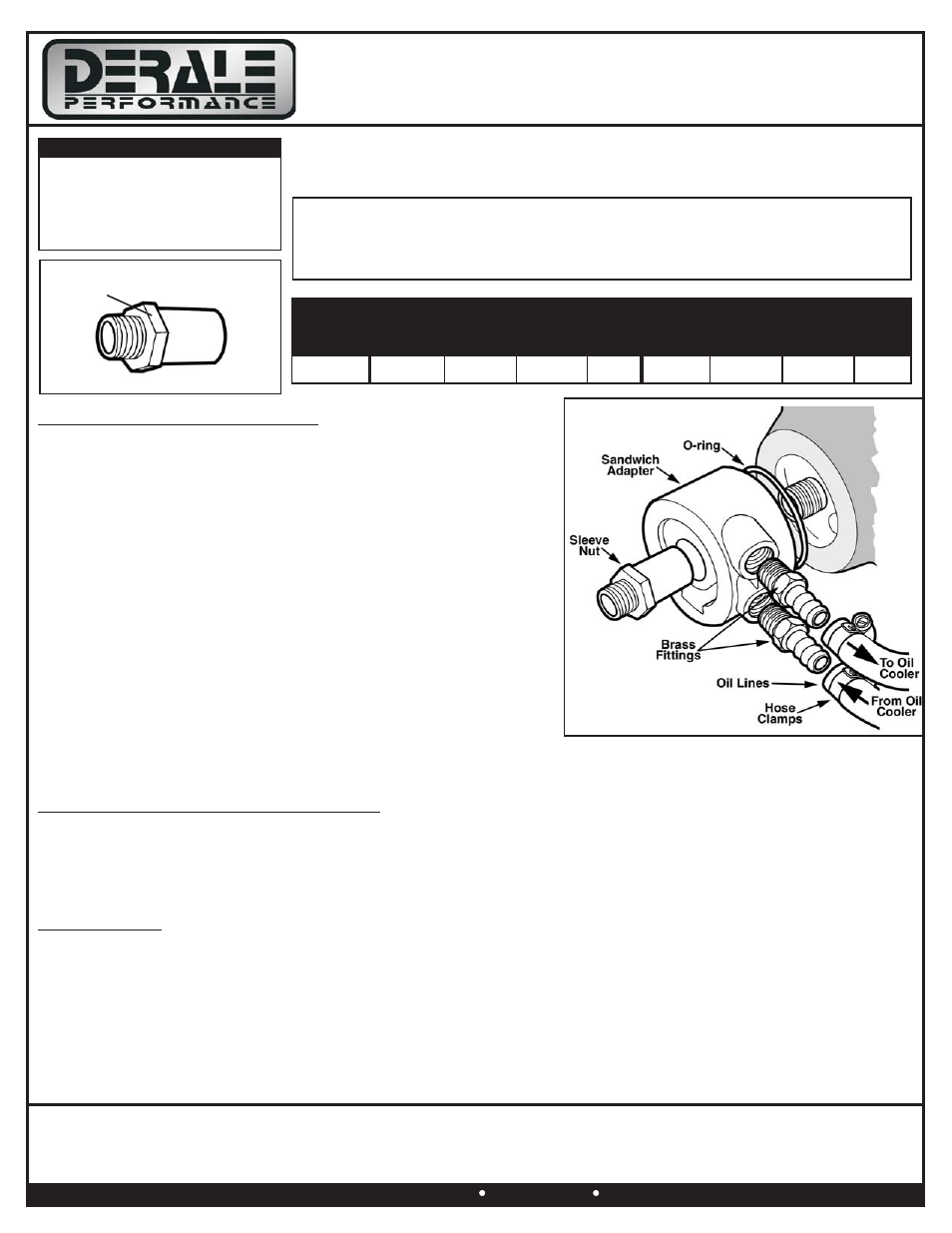

Diagram #2

Actual Sandwich

Adapter Not Shown

15720-InstructionSheet

Derale Performance, Los Angeles, CA

800.421.6288

www.derale.com

INSTALLATION INSTRUCTIONS

ENGINE SANDWICH ADAPTER KIT

PART # 15720

Please read these instructions completely

before beginning installation

KIT CONTENTS

QTY. DESCRIPTION

1

Sandwich Adapter

1

O-ring

2

1/2” NPT x 1/2” Barb Fittings

1

13/16-16 Sleeve Nut

IMPORTANT

In most cases the Factory Oil Filter will work with the supplied sandwich adapter. In some

applications where the frame or exhaust system interferes with the new filter depth we

recommend using a shorter filter length. See the chart below for possible filter options.

SLEEVE NUT

Diagram #1

SANDWICH ADAPTER INSTALLATION

The Sandwich Adapter fits between the oil filter and the engine block.

Before removing the oil filter, check the clearance between the bottom of

the filter and the closest vehicle obstruction. If there are none, then

proceed with the installation. Otherwise, the Sandwich Adapter is 2-1/4”

Thick, so you will need 2-1/2” more clearance then stock. If you determine

that the stock filter will not fit, refer to the Filter Chart for alternative filter

heights.

1. Remove the factory oil filter from the vehicle.

2. Take the Sandwich Adapter and the two Hose Barb Fittings provided.

Using Teflon Tape or a suitable sealant, screw the Hose Barb Fittings

clockwise into the Sandwich Adapter until snug. (See Diagram #2)

3. Using a wrench tighten the two Hose Barb Fittings.

4. Take the O-ring provided, apply a thin film of oil and install into the

O-ring groove on the Sandwich Adapter. (See Diagram #2)

5. Making sure the engine block filter landing is clean from oil and dirt,

take the Sleeve Nut, Sandwich Adapter, O-ring, and install onto engine

sliding the Sleeve Nut thru the Sandwich Adapter. Turn sleeve nut

clockwise onto the engines filter nipple. (See Diagram #2)

6. Using a torque wrench, torque the Sleeve Nut to 20 ft. lbs.

1. Install both ends of the hose onto the Hose Barb Fittings, forming a loop.

2. Take the looped end and route the hose to the oil cooler making sure to stay clear of sharp objects, exhaust systems, etc.

All bends in hose need to have a minimum radius of 5” or the diameter of a small coffee can.

3. Cut and attach hoses to the oil cooler. Secure hoses using zip ties.

1. Before starting the vehicle, check engine oil level and add accordingly.

2. Always check fluid levels on a flat surface.

3. After installation and vehicle has completely warmed up, recheck fluid level and inspect all connections for leaks.

ROUTING HOSES (HOSE SOLD SEPARATELY)

SYSTEM CHECK

Note:

Warning: Installation of accessories should only be undertaken by those with mechanical knowledge and are familiar with working on

vehicles. Always use eye protection (goggles, safety glasses or shield). Park the vehicle in a well lit area, on level ground and apply the

parking brake. Only work on a cold vehicle that has been sitting overnight, failure to do so will result in severe burns and injury. Before starting

the vehicle, make sure no tools or any other items are left under hood that could interfere with or be drawn into moving parts of the engine.

Failure to follow instructions can lead to severe damage and personal injury.

FRAM

WIX

FRAM

WIX

THREAD

FILTER

FRAM

FILTER

WIX

FILTER

FRAM

FILTER

WIX

SIZE

HEIGHT

P/N

HEIGHT

P/N

HEIGHT

P/N

HEIGHT

P/N

5.25

PH13

5.17

51060

4.06

PH30

4.33

51069

13/16-16