GE P&W Spiral Wound Membranes - MUNI NF Series User Manual

Muni nf series, Fact sheet, Figure 1: high flow rate at low pressure drop

Fact Sheet

Find a contact near you by visiting www.gewater.com and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2013, General Electric Company. All rights reserved.

FS1274EN.doc Nov-13

MUNI NF Series

Membrane Elements for Municipal Drinking Water Plants

The GE Water & Process Technologies MUNI NF se-

ries is engineered to provide a low pressure and

cost effective nanofiltration alternative to standard

RO treatment. The resulting product is virtually free

of any harmful biological matter. Performance is

characterized by hardness reduction, color removal,

and organic pollutants reduction (such as the pre-

cursors to THM).

The MUNI NF membrane element is tested and cer-

tified by NSF international against NSF/ANSI Stand-

ard 61 for material requirements only.

The MUNI NF membrane is an element following a

100% Wet Test Quality Assurance.

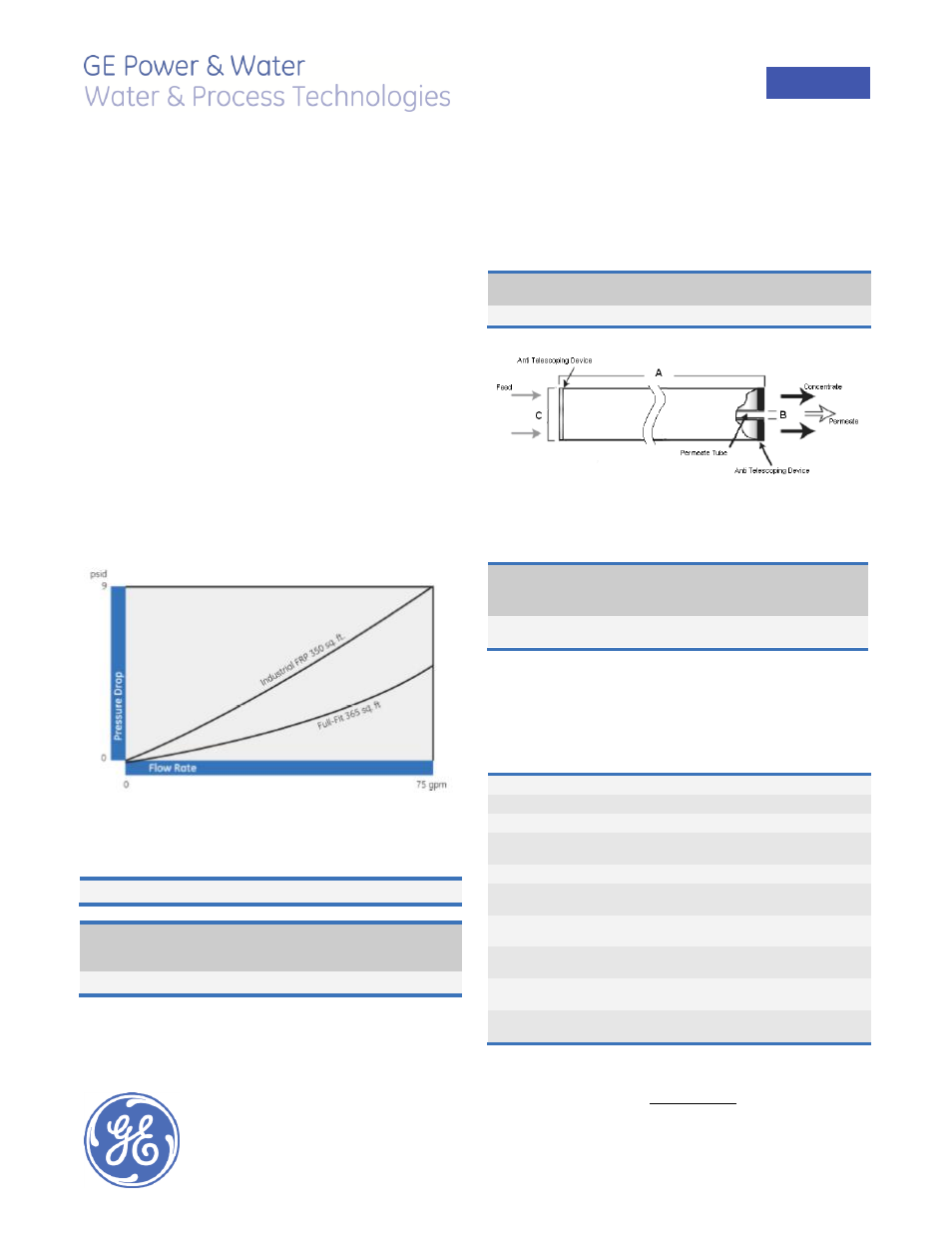

Figure 1: High Flow Rate at Low Pressure Drop

Table 1: Element Specification

Membrane

Thin-Film Membrane (TFM*)

Model

Average

permeate flow

gpd (m

3

/day)

1,2

Average

MgSO

4

rejection

1,2

MUNI-NF-400

11,500 (43.5)

98.0%

1

Average salt rejection after 24 hours operation. Individual flow rate may vary

+25%/-15%.

2

Testing conditions: 2,000ppm MgSO

4

solution at 110psi (760kPa) operating

pressure, 77 °F, pH 7.5 and 15% recovery.

Model

Active area

ft

2

(m

2

)

Outer wrap

Part

number

MUNI-NF-400

400 (37.2)

Fiberglass

1242400

Figure 2: Element Dimensions Diagram – Female

Table 2: Dimensions and Weight

Model

1

Dimensions, inches (cm)

Boxed

A

B

2

C

3

Weight

lbs (kg)

MUNI-NF-400

40.0

(101.6)

1.125

(2.86)

7.9

(20.1)

32

(14.5)

1

These elements are dried and bagged before shipping.

2

Internal diameter.

3

The element diameter (dimension C) is designed for optimum performance in GE

Water & Process Technologies pressure vessels. Others pressure vessel dimension

and tolerance may result in excessive bypass and loss of capacity.

Table 3: Operating and CIP parameters

Typical Operating Pressure

70-300psi (483 – 2,069kPa)

Typical Operating Flux

10-20GFD (15-35 LMH)

Maximum Operating Pressure

600psi (4,137kPa)

Maximum Temperature

Continuous Operation: 113°F (45°C)

Clean-In-Place (CIP): 104°F (40°C)

Minimum Crossflow

30gpm (6.8m3/h)

pH Range

Continuous Operation: 3.0-9.0,

Clean-In-Place (CIP): 2.0-10.5

Maximum Pressure Drop

Over an element: 12psi (83kPa)

Per housing: 50psi (345kPa)

Chlorine Tolerance

1,000+ ppm-hours,

dechlorination recommended

Feedwater

NTU < 1

SDI < 5

Recommended single element

recovery

< 15 %