Typical applications, For more information – GE P&W GenGard Corrosion Treatment Programs User Manual

Page 2

Page 2

Fact Sheet

tection. HRA is halogen stable and capable of

maintaining effective corrosion inhibition even in

the presence of chlorine and bromine-based bio-

cides. Conventional azole inhibitors, such as tolyl-

triazole and benzotriazole, are readily halogenated

in the cooling water, preventing the establishment

and repair of a protective film on the metal surface.

HRA maintains its activity both in the water and on

the metal surface, ensuring continuous protection

for copper alloys. HRA also reduces copper levels in

the cooling water, minimizing copper discharge and

effectively controlling destructive galvanic pitting

on steel surfaces.

Typical Applications

The GenGard GN7000 series of products are

designed for cooling systems operating in the near-

neutral pH 6.8 - 7.8 range. They utilize high levels of

inorganic phosphate to promote the formation of a

thin, protective iron oxide film on steel surfaces.

This protective oxide film is extremely tenacious

and does not interfere with heat transfer. STP pro-

vides the necessary calcium phosphate control to

maintain system cleanliness and uninterrupted op-

eration. (See Figure 2.)

The GenGard GN8000 series of products are

designed for waters in the less corrosive alkaline

range above pH 7.8. GN8000 products utilize AEC as

the basic component to allow operation at highly

alkaline conditions without concern for scale forma-

tion.

For More Information

For more information on the GenGard Technology,

please contact a GE account representative or visit

us on the web at www.ge.com/water.

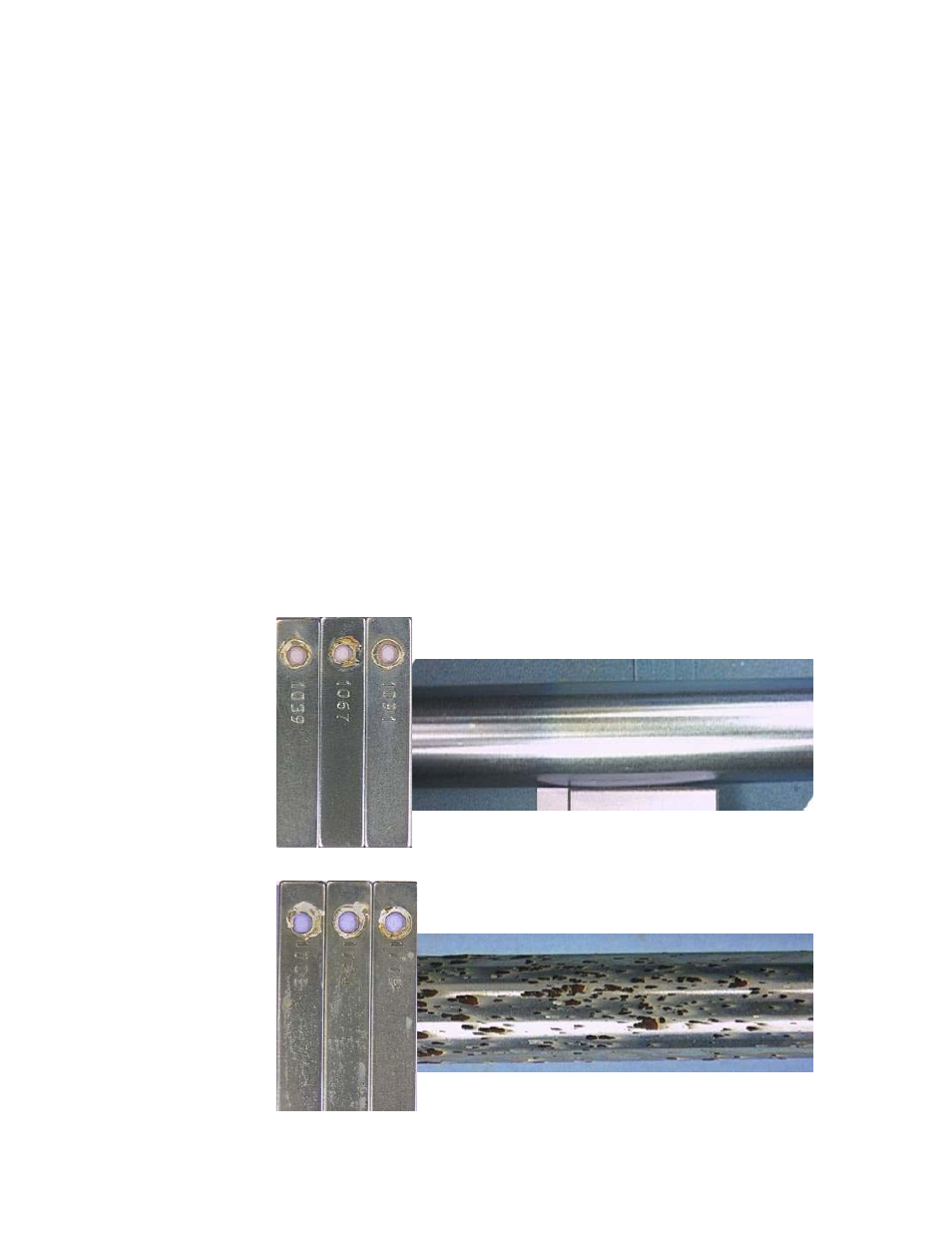

Figure 2: Comparison of Halogen Stable vs. Conventional Treatment, neutral pH,

phosphate program, continuous chlorination (0.5 - 1.0 ppm free Cl2)

8 ppm AA/AMPS /BZT

LCS - 1.4 mpy

ADM - 0.6 mpy

2 ppm STP/HRA

LCS <0.5 mpy

ADM <0.2 mpy