Key applications, Technology and operation, Supercritical water oxidation (scwo) – GE P&W Wastewater TOC Analyzer User Manual

Page 2

Key Applications

•

Petrochemical

•

Food and Beverage

•

Chlor-alkali Chemistry

•

Pharmaceutical

•

Environmental Labs

•

Manufacturing

•

Municipal/Industrial Wastewater

•

Power

•

Research

•

Pulp and Paper

•

Brine and Seawater

•

Unconventional Oil & Gas

Technology and Operation

The InnovOx features three main steps, each with

significant process innovations:

Sample Handling and Reagent Mixing

The InnovOx ensures superior sample representa-

tion and accuracy by processing a large sample

volume and thoroughly agitating the sample in

the Sample Mixing Chamber. The sample and re-

agents are added through a sample coil delivery

system which prevents syringe contamination.

Supercritical Water Oxidation (SCWO)

Using a patented SCWO technique (see sidebar below), the

Sievers InnovOx takes the water sample to a supercritical

state by increasing the temperature, and subsequently the

pressure, within the reactor. The properties of supercritical

water enable an ultra-efficient oxidation of TOC to carbon

dioxide, even in the presence of chloride and other in-

organic species

that negatively interfere with traditional

oxidation techniques.

NDIR Detection

The InnovOx uses a highly stable, nondispersive infrared

(NDIR) detector. Unlike other NDIR detectors, the InnovOx

NDIR has no moving parts, and features tight temperature

control of the IR source and detector.

Visit the library at www.geinstruments.com to see animations of

key components and the innovative SCWO oxidation technique.

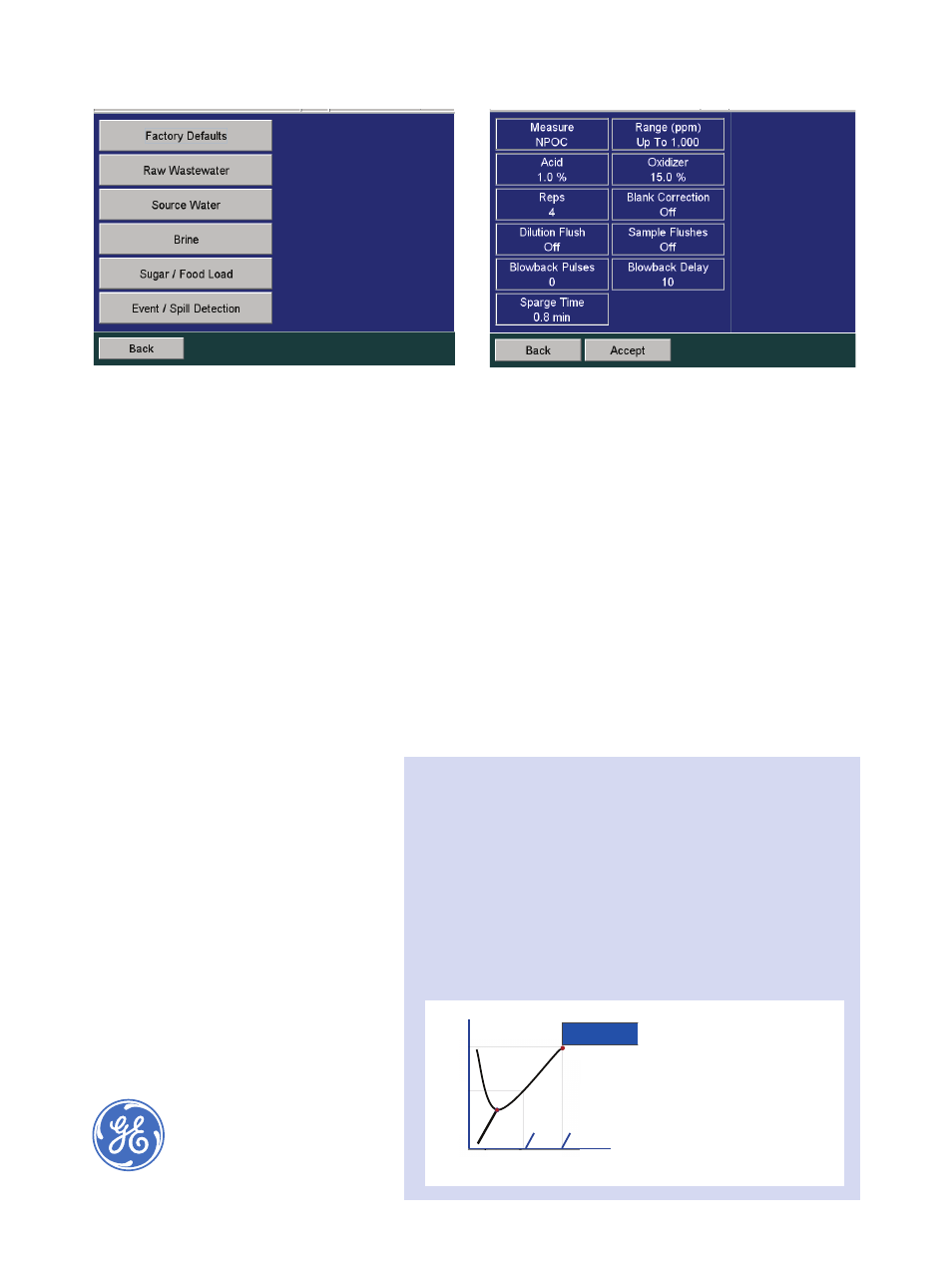

InnovOx On-Line TOC Analyzer Touch-Screen Interface

InnovOx On-Line TOC Analyzer Touch-Screen Interface

Supercritical Water Oxidation (SCWO)

Supercritical Water Oxidation (SCWO) was originally developed to

treat large volumes of aqueous waste streams, sludges, and contami-

nated soils. SCWO destroys organic wastes using an oxidant in water

and temperatures and pressures above the critical point of water:

375 °C (770 °F) and 22.1 mPa (3,200 psi). These conditions enable rapid

and complete oxidation of organic carbon to CO

2

.

Today, SCWO research and development is focused on treating a vari-

ety of toxic and hazardous organic wastes. GE Analytical Instruments

is the first company to use this technique in a commercial laboratory

TOC instrument.

Supercritical

fluid

critical point

pr

es

su

re

liquid

gas

solid

Supercritical fluid ―

not gas or liquid

critical point

temperature

o

C

pr

es

su

re (psi)

liquid

gas

solid

Supercritical Water

Oxidation (SCWO)

Organic + S

2

O

8

-

2

+ heat + pressure

→ CO

2

+ H

2

O + SO

4

-2

3200

15

375

o

C

normal

boiling

point