GE P&W Spiral Wound Membranes - 416-UF(PS1) User Manual

Uf(ps1), Fact sheet, Table 1: element specifications

Fact Sheet

Find a contact near you by visiting www.gewater.com and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2013, General Electric Company. All rights reserved.

FSps416UF(PS1)_EN.doc Sep-13

416-UF(PS1)

UF Full-Fit* Membrane Element

Post-Treatment of RO and NF

Table 1: Element Specifications

Model

416-UF(PS1)

Flux Rate

GFD: 10-20

(lh-1m-2): 15-35

Active Area

Ft

2

: 80

m

2

: 7.4

Molecular Weight Cut-off Daltons

6,000

Part Number

1224015

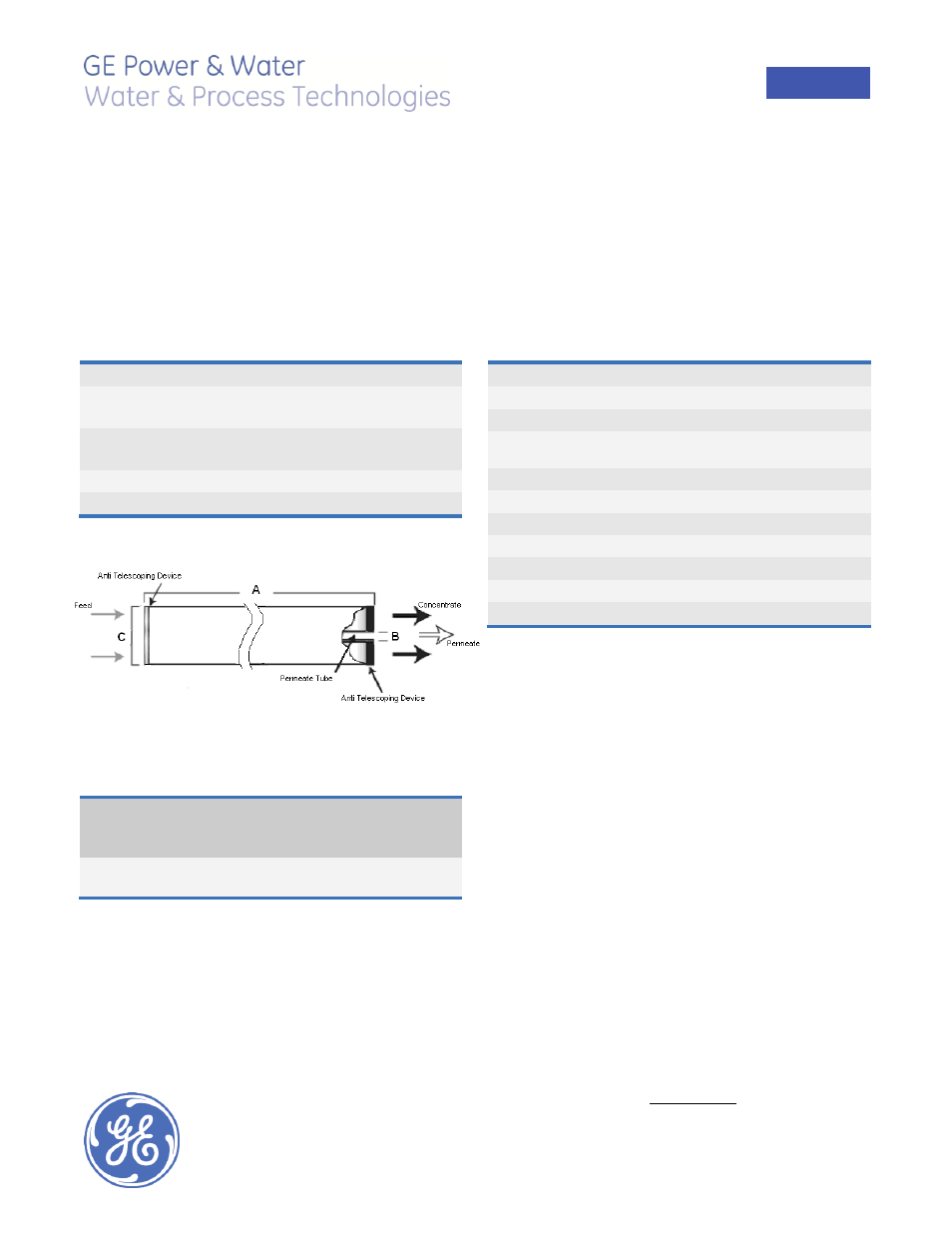

Figure 1: Element Dimensions Diagram

Table 2: Element Dimensions and Weight

Model

Dimensions, inches (mm)

A

B

C

1

Weight

lbs (kg)

416-UF(PS1)

40

(1016)

0.775

(20)

3.94

(100)

11

(5)

1

The element diameter (dimension C) is designed for optimum perfor-

mance in GE Water & Process Technologies pressure vessels. Other

pressure vessel dimension and tolerance may result in excessive by-

pass

Table 3: Operating and Design parameters

Membrane

Polyethersulfone

Typical Operating Pressure

30-60psig (206-414 kPa)

Maximum Pressure

300psig (2095 kPa)

Maximum Pressure Drop

10 psig (69 kPa) per element

50 psig (345 kPa) per vessel

Chlorine Tolerance

5,000 ppm+ days

Typical Operating Flux

10-20 GFD (17-34 L.H-1.M-2)

Operating pH Range

2.0-11.0

Cleaning pH Range

2.0-11.5

Maximum Temperature

122°F / 50°C

Feed NTU

<1

Feed SDI

<5

Notes:

The Langelier Saturation Index (LSI) of the concen-

trate must be negative to minimize the posibility of

calcium scale formation on the membrane surface.

At start-up the first two hours of permeate should

be discarded because of element preservative.

Storage conditions should be at a minimum of:

<100°F, dry, in original carton and not in direct sun-

light.