GE P&W Spiral Wound Membranes - Duratherm STD Series User Manual

Duratherm* std series, High temperature pure water elements, Description and use

Fact Sheet

Find a contact near you by visiting www.gewater.com and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2013, General Electric Company. All rights reserved.

FS1271EN.doc Jul-13

Duratherm* STD Series

High Temperature Pure Water Elements

Description and Use

The Duratherm* STD Series is specifically designed

to maximize the benefits of continuous high tem-

perature operation as well as hot water sanitiza-

tion for industries willing to maximize energy

recovery and use hot purified water.

Separation system sanitization protocol is per-

formed via periodic exposure to temperature as

high as 90°C (194°F) at minimum feed pressure to

kill microorganisms by denaturation and coagula-

tion of the proteins chains.

The Duratherm STD are suitable for separation

systems purifying water at temperature up to

70°C (158°F) in low crossflow environment and no

suspended solids.

This Series includes a variety of size 8” and 4” di-

ameters. All element constructions include

Durasan* Cage outer wrap, Polysulfone ATD and

central tube.

Features and benefits

Prevent bio-fouling development

No disposal costs

100% wet testing Quality Assurance

Durable construction

Sanitization on the permeate side

Markets

Food / Beverage

BioPharm

Electronics

Chemical

Table 1: Element Specification

Membrane

A-Series, Thin-film membrane (TFM*), PES

Model

Maximum

crossflow

gpm (m

3

/h)

Average

permeate flow

gpd (m

3

/day)

Average

NaCl Rejection

Duratherm STD RO4040

1,2

20 (4.5)

2,300 (8.7)

99.5%

Duratherm STD RO8040

1,2

65 (14.8)

9,900 (37.5)

99.5%

Duratherm STD UF8040HR

65 (14.8)

-

5,000Da

1

Testing conditions: 2,000ppm NaCl solution at 225psig (1,550kPa) operating

pressure, (25°C) 77°F, pH7.5 and 15% recovery before any hot water sanitiza-

tion.

2

Average salt rejection after 24 hours operation. Individual flow rate may vary

+25%/-15%. Final permeate flow rate is subject to variations in the heat treat-

ments. In most cases, the permeate flow rate after heat treatments will stabi-

lize at 30-50 percent below the nominal flowrate before heat treatment. For a

conservative design, consider a permeate flow reduction of 50%.

Model

Active area

ft

2

(m

2

)

Outer wrap

Part

number

Duratherm STD RO4040

90 (8.4)

Cage

1228197

Duratherm STD RO8040

355 (33.0)

Cage

1228225

Duratherm STD UF8040HR

360 (33.4)

Cage

1207315

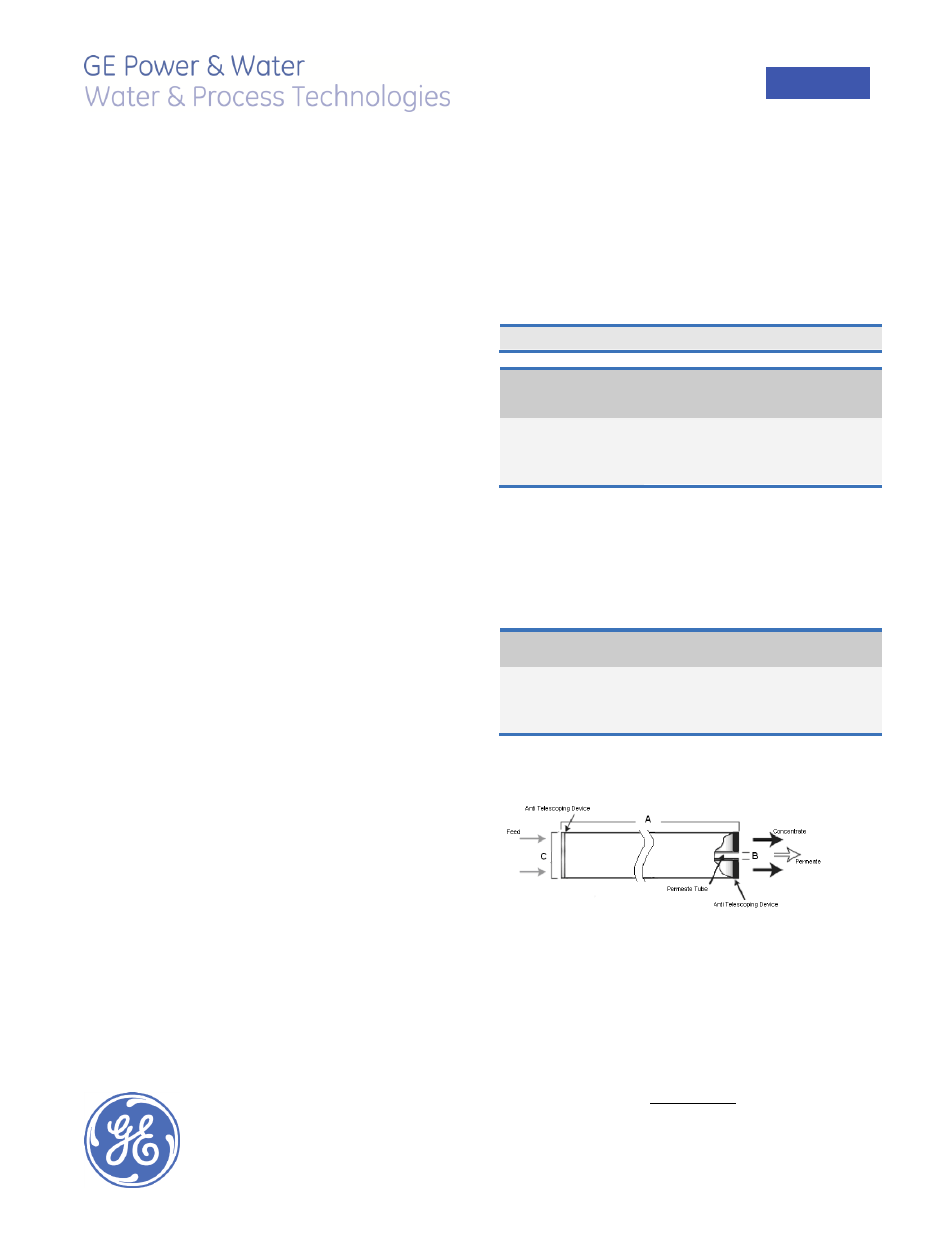

Figure 1: Element Dimensions Diagram (Female)