Material of construction, Quality assurance – GE P&W Electrodialysis Reversal (EDR) User Manual

Page 2

Page 2

FS1242EN

TOC ..................................................................... < 15 ppm (mg/l)

COD ....................................................... < 50 ppm (mg/l) as O

2

Iron .................................................................... < 0.3 ppm (mg/l)

Manganese, Aluminum ........................... < 0.1 ppm (mg/l)

H2S .................................................................... < 0.1 ppm (mg/l)

Allowable Intermittent Levels:

SDI (5 min. test) ......................................................................... 15

Turbidity ............................................................................2.0 NTU

Free Chlorine .................................................................. 30 mg/l

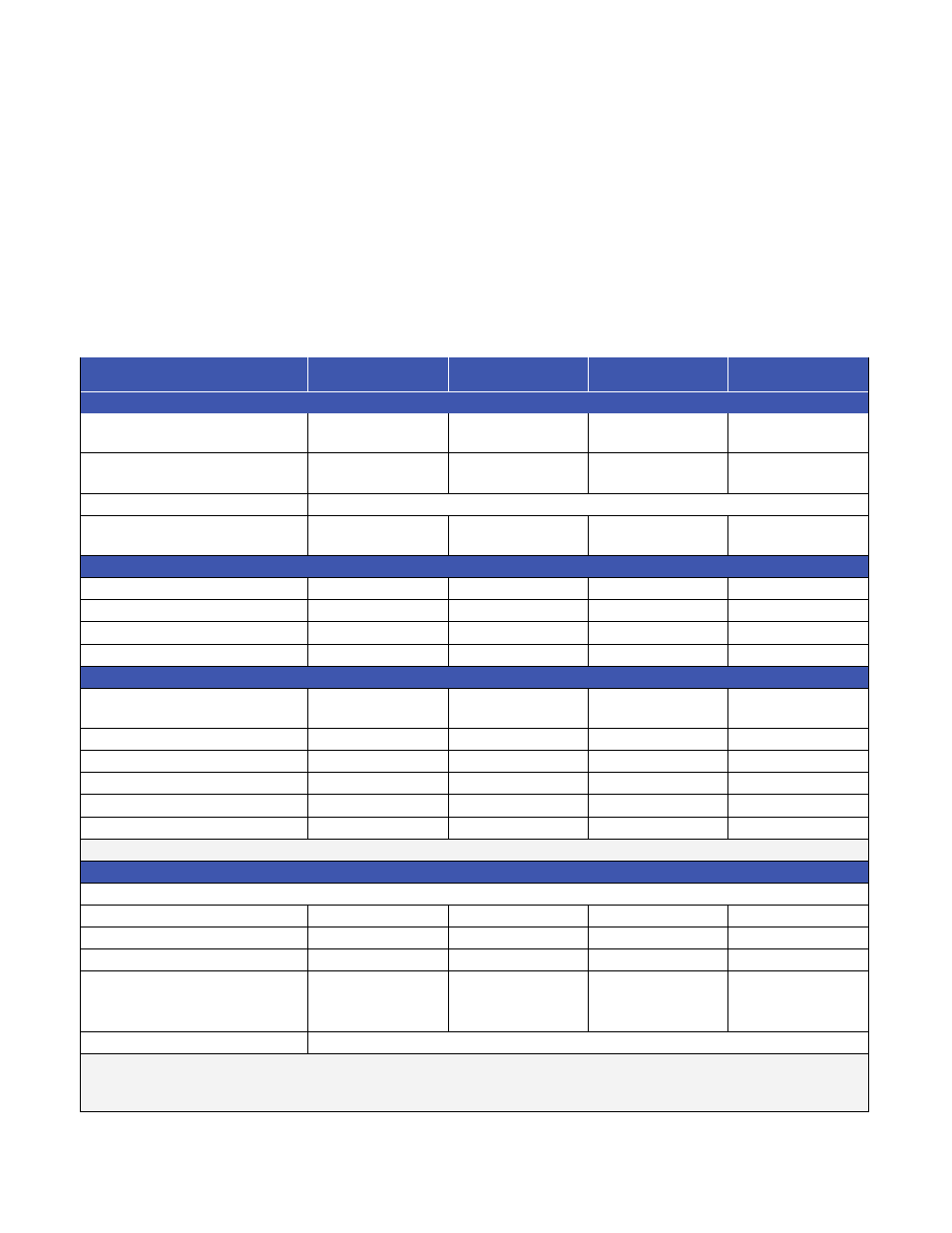

Material of Construction

Welded Frame................................... Painted Carbon Steel

Dilute and Concentrate Piping ...................... Sch. 80 PVC

Flanges .................................................................................... ANSI

Concentrate Pump ................... Single-stage Centrifugal

Rectifier ......................................................................... NEMA 3R

Control Panel ................................................................. NEMA 4

Quality Assurance

Certification ............................................................................... UL

Facility ................................................................. ISO 9001:2000

EDR 2020 2 & 4 Line Standard Systems

MODEL

2020-2L-2S

2020-2L-3S

2020-4L-2S

2020-4L-3S

Flow Rates

Product Flow Nominal

280 gpm

63.6 m

3

/h

260 gpm

59.1 m

3

/h

560 gpm

127.2 m

3

/h

520 gpm

118.2 m

3

/h

Product Flow Range

165 to 325 gpm

37.5 to 73.8 m

3

/h

165 to 270 gpm

37.5 to 61.3 m

3

/h

325 to 655 gpm

73.8 to 148.8 m

3

/h

325 to 545 gpm

73.8 to 123.8 m

3

/h

Concentrate Outlet Flow

Depends on recovery and product

Electrode Outlet Flow

2.2 gpm

8.3 lpm

2.5 gpm

9.5 lpm

4.3 gpm

16.3 lpm

5.0 gpm

19 lpm

General Information

Number of Stacks

4

6

8

12

Number of Lines

2

2

4

4

Number of Stages

2

3

2

3

Type of Stack

MK-IV-2

MK-IV-2

MK-IV-2

MK-IV-2

Dimensions

System Dimensions

Width x Length

90” x 309”

(2.3 x 7.9 m)

90” x 375”

(2.3 x 9.5 m)

169” x 493”

(4.3 x 12.5 m)

169” x 625”

(4.3 x 15.9 m)

Inlet Piping

4” (10 cm)

4” (10 cm)

6” (15 cm)

6” (15 cm)

Product Outlet Piping

4” (10 cm)

4” (10 cm)

6” (15 cm)

6” (15 cm)

Off-Spec Outlet Piping

4” (10 cm)

4” (10 cm)

6” (15 cm)

6” (15 cm)

Electrode Outlet Piping

3” (8 cm)

3” (8 cm)

3” (8 cm)

3” (8 cm)

Concentrate Outlet Piping

1.5” (4 cm)

1.5” (4 cm)

2” (5 cm)

2” (5 CM)

Note: all piping sizes are provided for nominal flow rates at 85% recovery.

Electrical

Maximum Rectifier Output (Per Stack Basis)

Stage 1

590VDC, 46A

590VDC, 26A

590VDC, 46A

590VDC, 26A

Stage 2

518VDC, 18A

518VDC, 14A

518VDC 18A

518VDC, 14A

Stage 3

420VDC, 7.5A

420VDC, 7.5A

Connection Requirement

(Includes Feed pump, which may

be supplied by others)

140 KVA

107 KVA

276 KVA

209 KVA

Typical Power consumption

2 – 4 kWh/1,000 gallons of product water

Performance, number of stages and cell pairs, recovery and power consumption are dependent on inlet feed water

quality and temperature. A Watsys projection must be completed by an authorized GE Water & Process Technologies

design representative for proper system design & for any performance guarantee to be provided.