GE P&W HERO High Efficiency Reverse Osmosis User Manual

Page 2

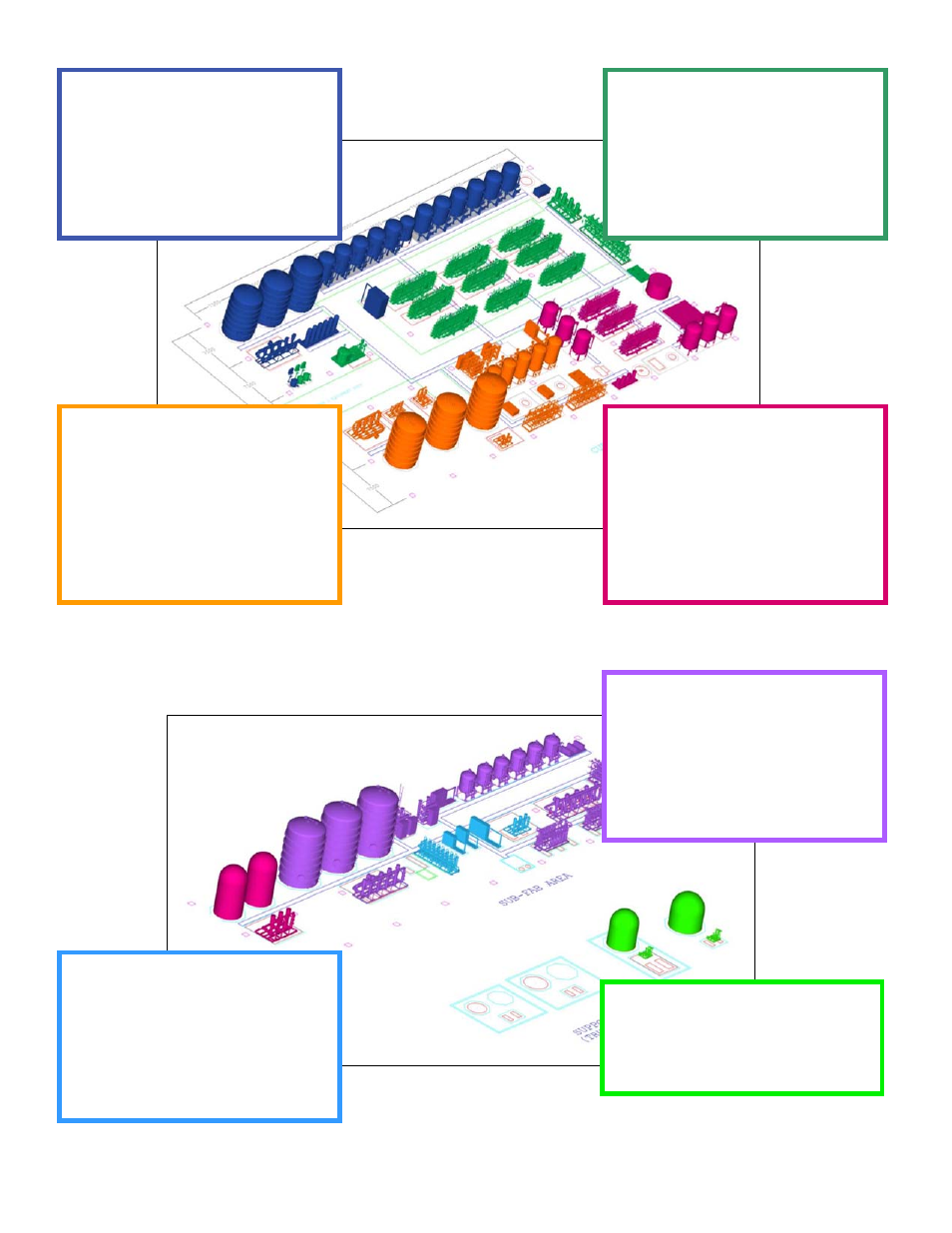

MOD-2 – HERO System

Either a single-pass or a tw

Page 2

FSroHERO_EN.doc

.

MOD-4 – Polishing Loop / Cold UPW

Product water from Module 3 (above)

is collected in a blanketed storage

tank. A TOC reducing UV and cooling

heat exchanger serve as a precursor

to polishing mixed beds and a final

cold ultrafiltration (UF) step.

MOD-5 – Hot UPW

A side stream of polished (pre-UF) wa-

ter from Module 4 is diverted as feed

to this module. Product Water is

brought to temperature before going

through a hot UF step. The UF perme-

ate then goes to the plant for con-

sumption

MOD-7 – Support Equipment

Miscellaneous system support opera-

tions include necessary regeneration

storage tanks and transfer pumps.

o-pass RO

system operating at 90%+ overall

recovery. The RO system is preceded

by cartridge filtration and a

degasification step. Optional CIP

System for RO cleaning.

MOD-3 – Primary UPW

A storage tank with a nitrogen blanket

is provided for RO permeate collection.

From the storage tank, product is

transferred through TOC UV units to

either electrodeionization (EDI) stacks

or primary mixed beds. Finally, gas-

transfer membranes are used to

remove CO2 and further enhance

product water quality.

MOD-6 – Rinse Reclaim / Recycle

Last rinse water from the cold and hot

UPW manufacturing operations are

diverted to this module for treatment

and reuse. The heart of this process is

a patented reverse osmosis step, with

overall recovery greater than 90%.

MOD-1 – Pretreatment

Unit operations selected based on

feed water characteristics such as

hardness and alkalinity. In general,

this module can consist of blend water

tank and pumps, prefiltration, heat

exchanger, softener, and weak or

strong acid cation columns.

Figure 2: UPW Design Modules