GE P&W Spiral Wound Membranes - MW Series User Manual

Mw series, Industrial oil/water separation uf elements, Fact sheet

Fact Sheet

Find a contact near you by visiting www.gewater.com and clicking on “Contact Us” .

* Trademark of General Electric Company; may be registered in one or more countries.

©2013, General Electric Company. All rights reserved.

AM-FSpwMWSeries_EN.doc Nov-13

MW Series

Industrial Oil/Water Separation UF Elements

The M-Series Ultrafillic* membranes are made of

polyacrylonitrile (PAN) polymer. This membrane is

characterized by a pore size of 0.01 microns with an

approximate molecular weight cut-off of 20K-50K

Dalton. To avoid fouling by "free" oils, the MW –

series elements have been engineered to be ex-

tremely hydrophilic (water attracting) as compared

to conventional membranes that are oleophilic (oil

attracting).

MW Elements are used for oil/water separation and

suspended solids removal. They are also used as

pretreatment of process water before reverse os-

mosis or nanofiltration.

Table 1: Element Specification

Membrane

M-series, polyacrylonitrile

Model

Spacer

mil (mm)

Active area

ft

2

(m

2

)

Outer wrap

Part

number

MW2540F30

30 (0.76)

23 (2.1)

Fiberglass

1233383

MW4040F50

50 (1.27)

65 (6.0)

Fiberglass

3050562

MW8040C50

50 (1.27)

266 (24.7)

Cage

1220654

MW8040F50

50 (1.27)

261 (24.2)

Fiberglass

1229852

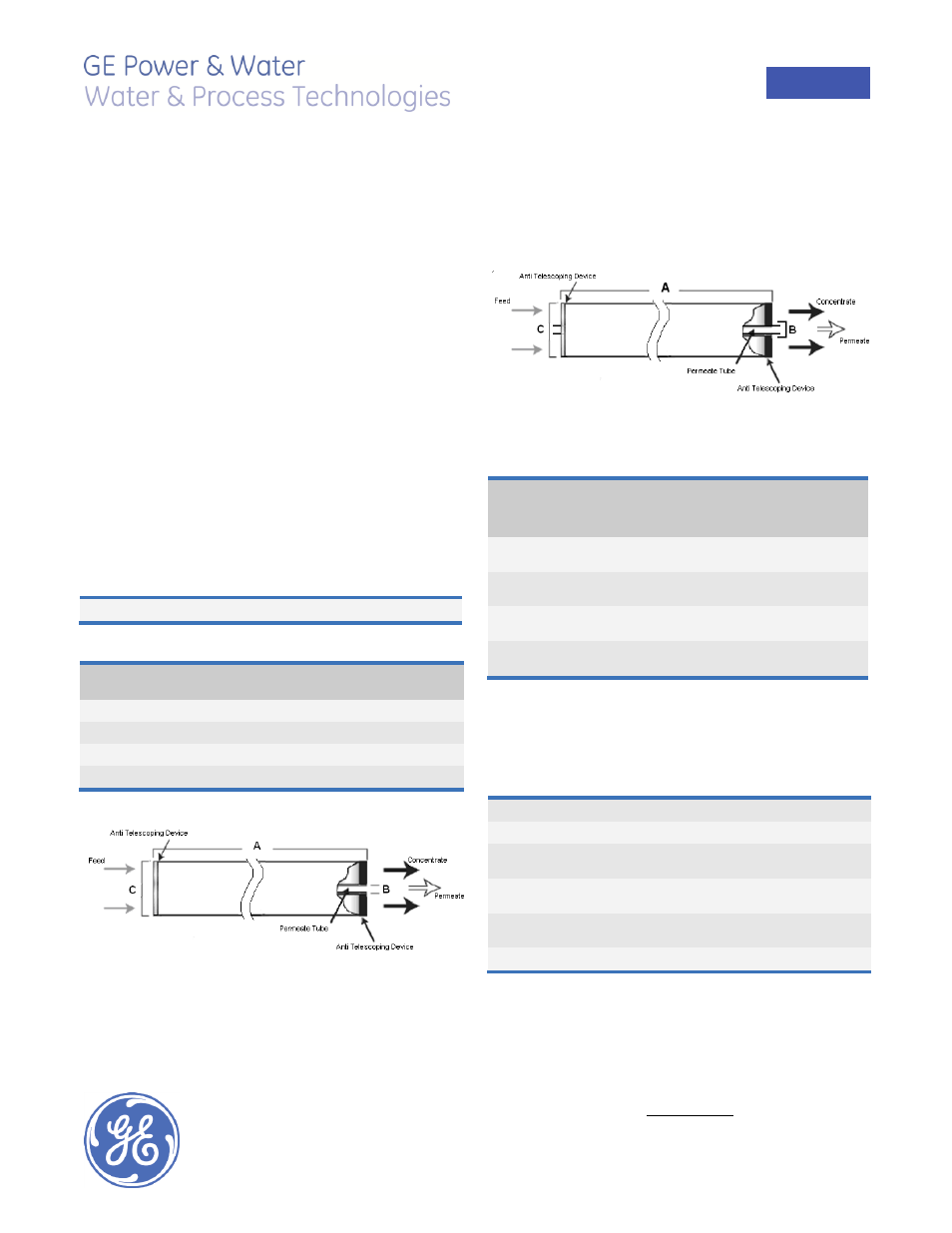

Figure 1: Element Dimensions Diagram, Female 8040

Figure 2: Element Dimensions Diagram, Male 2540 & 4040

Table 2: Dimensions and Weight

Model²

Dimensions, inches (cm)

Boxed

A

B

1

C

3

Weight

lbs (kg)

MW2540F30

40.0

(101.6)

0.75

(1.9) OD

2.4

(6.1)

4

(1.8)

MW4040F50

40.0

(101.6)

0.75

(1.9) OD

3.9

(9.9)

9

(4.1)

MW8040C50

40.0

(101.6)

1.125

(2.86)

7.9

(20.1)

29

(13.2)

MW8040C50

40.0

(101.6)

1.125

(2.86)

7.9

(20.1)

29

(13.2)

1

Internal diameter unless specified OD (outside diameter).

²These elements are bagged dry before shipping.

3

The element diameter (dimension C) is designed for optimum performance in GE

pressure vessels. Others pressure vessel dimension and tolerance may result in

excessive bypass and loss of capacity.

Table 3: Operating and CIP parameters

Typical Operating Flux

5 - 20 GFD (8 – 34 LMH)

Maximum Operating Pressure

100psi (700kPa)

Maximum Temperature*

Continuous operation: 122°F (50°C)

Clean-In-Place (CIP): 122°F (50°C)

pH Range

Continuous operation:: 2-10,

Clean-In-Place (CIP): 3-9

Maximum Pressure Drop

Over an element: 15psi (103kPa)

Per housing: 60psi (414kPa)

Chlorine Tolerance

200,000 ppm-hours

* Element sized 8040 can be used at higher temperature. Please contact your GE

representative for further technical recommendations.

Note: Oil/water separation applications require the selec-

tion of materials compatible with the content of the high-

ly concentrated solution.