Validation services and additional products, Elements scope justification & rationale – GE P&W Ultrapure and Drinking Water TOC Analyzers - Sievers Technology Transfer Protocols User Manual

Page 2

© 2011. General Electric Company. All rights reserved.

Europe/Middle East/Africa

GE Analytical Instruments

Unit 3, Mercury Way

Urmston, Manchester

UK M41 7LY

T +44 (0) 161 864 6800

F +44 (0) 161 864 6829

The Americas

GE Analytical Instruments

6060 Spine Road

Boulder, CO 80301-3687 USA

T +1 800 255 6964

T +1 303 444 2009

F +1 303 444 9543

Asia Pacific

GE Analytical Instruments

7/F, Building 2, No. 5 Hua Tuo Rd.

ZhangJiang Hi-Tech Park, Pudong

Shanghai, China 201203

T +(8621) 38777735

F +(8621) 38777469

www.geinstruments.com

transitioning to “newer or updated versions” of these

analyzers, regulatory bodies have suggested that a series

of protocols be conducted when transferring to the new

instruments, technologies, or methods in order to ensure

that the new approach is suitable for the intended use per

current Good Manufacturing Practices (cGMPs).

The overall intent of GE Analytical Instruments’ Technology

Transfer Protocols is to align with ICH best practices that

the “new method, instrument, or equipment needs to

demonstrate that it performs equivalently to, or better

than, the previous validated method, instrument, or

equipment.” To achieve this goal, the protocols have been

designed emphasizing:

• “Like-for-like” methods through an instrumenta-

tion technology comparison

• Similarities in system suitability results to satisfy

compendial specifications

• An equivalency study of accuracy and precision

verification to satisfy regulatory guidelines

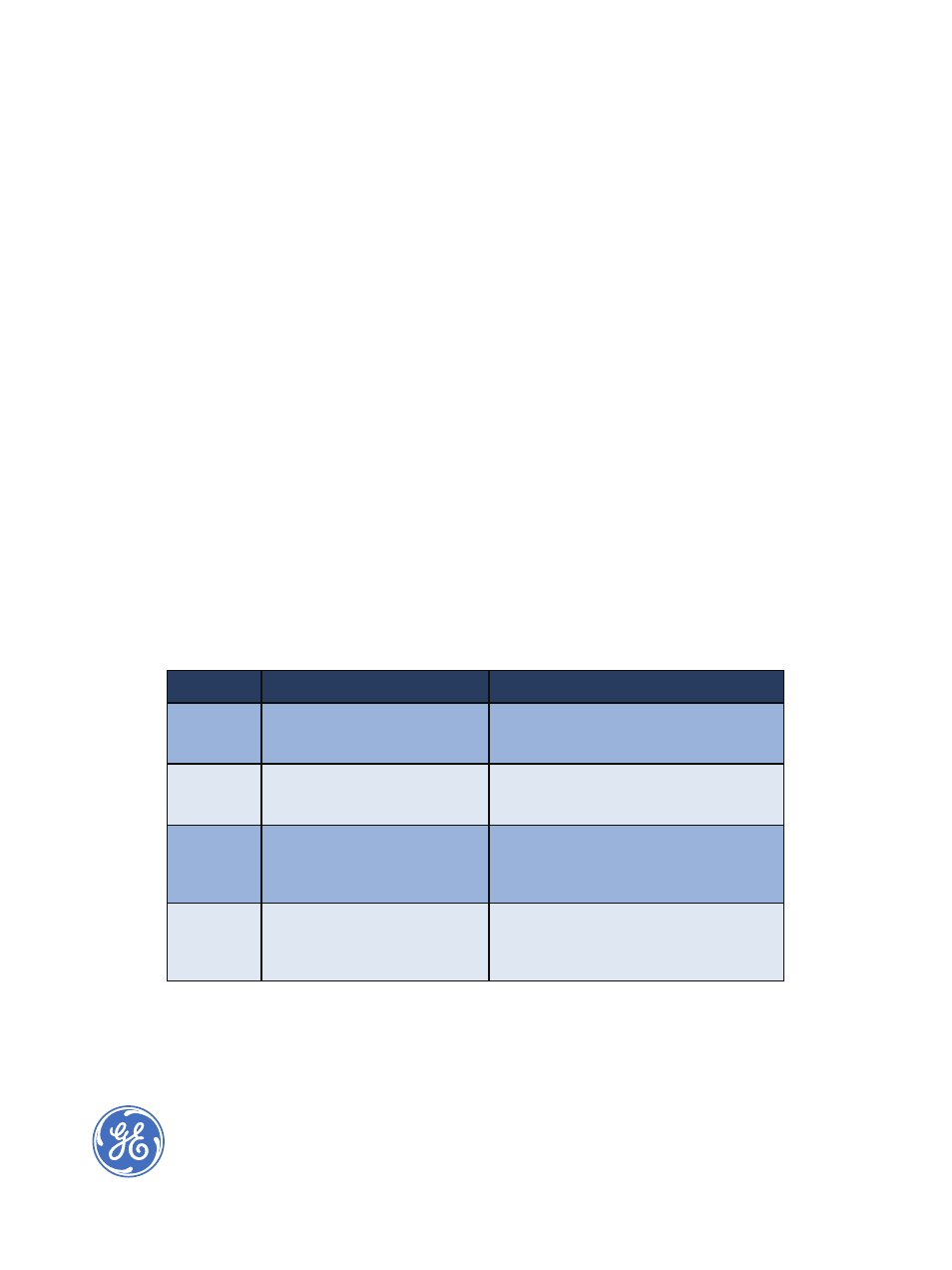

Table 1 summarizes each element, scope, justification

and rationale for the transition process incorporated in

these specific protocols.

Quality System Optimization (QSO)™ —

Accelerating the “Change” Process

The new transition protocols are part of GE Analytical

Instruments’ Quality System Optimization (QSO)

program. In 2010, QSO was introduced to the

pharmaceutical and biopharmaceutical industries as

a risk-based, scientific approach designed to efficiently

implement TOC analyzers for real-time release (RTR)

testing of pharmaceutical water. QSO provides the

framework for transitioning TOC testing from the

laboratory to the production floor within an integrated

compliance foundation. This type of “platform” was

used to design these transition protocols to accelerate

the process of changing from legacy technology to a

new technology.

Validation Services and Additional Products

In addition to these documents, GE Analytical Instruments

offers a one-day on-site validation service and specific

reference standards to ensure an efficient transition

to new TOC technology. Furthermore, these transition

protocols can be fully integrated into GE Analytical

Instruments VSPs and on-site validation services offering.

To explore these and other GE Analytical Instrument

products, please visit www.geinstruments.com or contact

your local representative.

300 00236 Rev A

MC11-188

Elements

Scope

Justification & Rationale

Design

Demonstration of ‘like-for-like’

technology comparison

Compare oxidation and detection techniques

based on the design of the TOC technology

and vendor specifications

Operation

Comparison test of the operational

suitability of the two analytical

instruments

Demonstrate that the transition to the new

instrumentation is suitable and operates

under actual conditions of use

Performance Equivalency test of validation

characteristics for performance of

the two analytical instruments

Justify that the transition to the new

instrumentation provides comparable results

based on accuracy and precision with the

same check standards

Transfer

Documentation to summarize both

methods are ‘like-for-like’ in design,

operation, and performance

The ‘like-for-like’ technology incorporated in

both instruments and results from the

comparison tests further facilitates the

transfer from one technology to another.

Table 1. GE Analytical Instruments’ Transition Protocols for the On-Line and Laboratory Analyzers