GE P&W Mobile Water Treatment Systems - Super 600 MobileRO User Manual

Super 600 mobilero, Reverse osmosis for high flow applications, Description and use

Find a contact near you by visiting www.ge.com/water and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2013, General Electric Company. All rights reserved.

FSmobSuper600_EN Feb-13

Fact Sheet

Super 600 MobileRO*

Reverse Osmosis for High Flow Applications

Description and Use

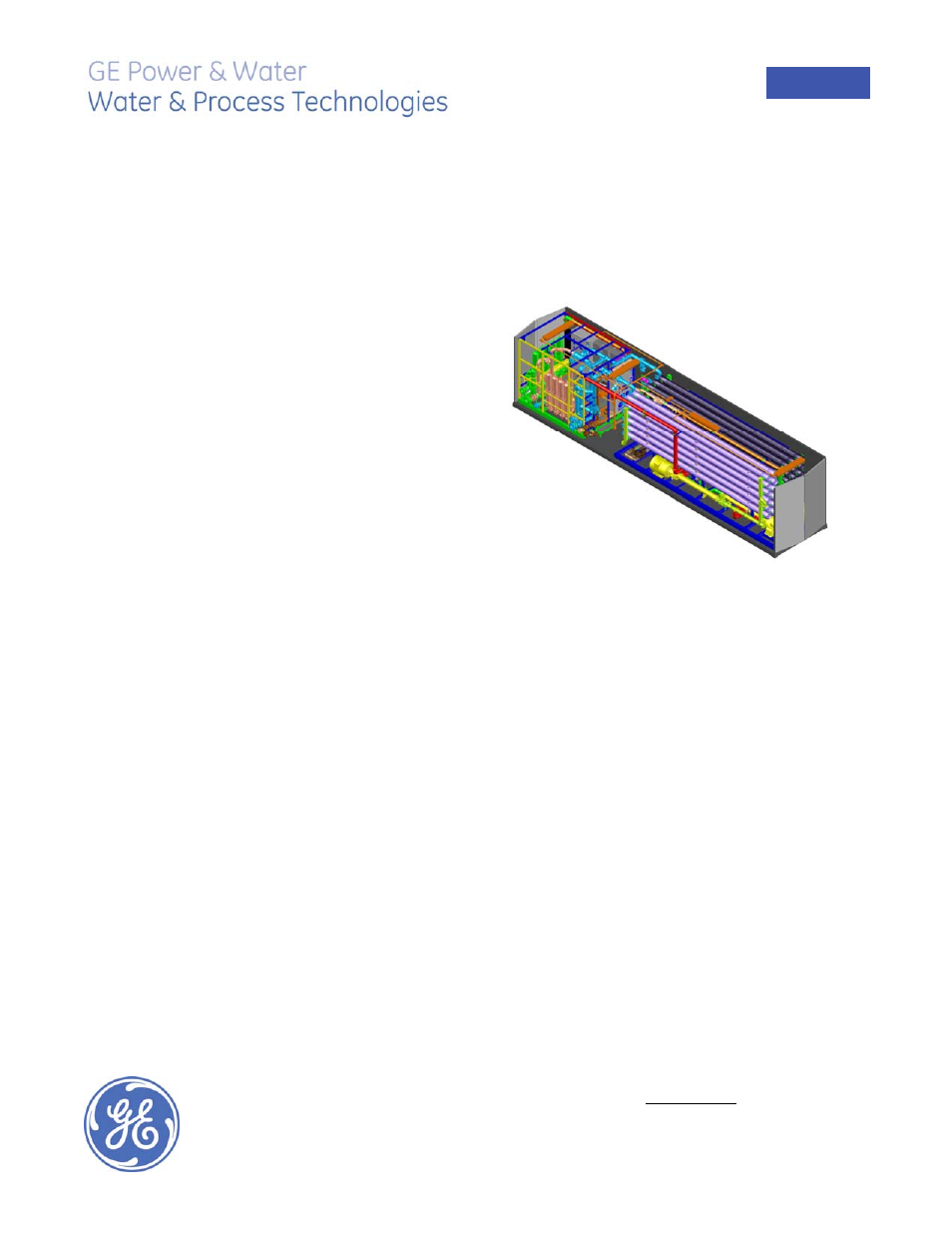

MobileRO reverse osmosis (RO) containers provide

emergency, interval, or long-term service to meet

the needs of industrial pure water users. The Super

600 MobileRO (Figure 1) is configured to produce up

to 650 gpm (148 m

3

/hr) in single-pass mode and up

to 350 gpm (79.5 m

3

/hr) in two-pass mode.

The unit contains the necessary hardware to moni-

tor the system operation including, inlet and per-

meate conductivity, inlet pH, inlet ORP meters;

concentrate and permeate flow meters; and pre-

filter, post-filter, primary and final pressure trans-

mitters.

The MobileRO container also includes the neces-

sary connections for chemical pumps essential for

maintaining the required water quality specifica-

tions.

Typical Applications

Standard Features

• RO configurable process flow to meet various

water demands; two pass or two train operabil-

ity in a single system

• Up to 650 gpm (148 m

3

/hr) in single-pass mode

or up to 350 gpm (79.5 m

3

/hr) in two pass mode

• Rejection rates of 97% or more

• Removes not only dissolved ions, but also bac-

teria, pyrogens, organics, particles, colloids,

color and oxidizing agents at up to 99.9%

• Emergency, interval, and long-term service for

RO water need

• VFD controlled high-pressure pumps

Figure 1: Super 600 MobileRO

• Centralized gauge panel for convenient system

monitoring

• 1-micron cartridge filtration for superior pro-

tection of reverse osmosis elements

• Able to combine with other GE Mobile units to

enhance system capability

General Properties

Single Pass Product Flow Up to ....................... 650 gpm

(148

m

3

/hr)

Two Pass Product FlowUp to ............................ 350 gpm

(79.5

m

3

/hr)

Recovery ................................................................. 60 to 75%

Nominal rejection ............................................... 95 to 99%

Operating range

1

.................... 35° to 105°F (2° to 40°C)

Minimum inlet pressure ......................... 30 PSIG (2 bar)

Maximum inlet pressure ........................ 60 PSIG (4 bar)

SDI

15

............................................................................................. 3

1

Flow limited by membrane flux at high temperatures