GE P&W Electrodeionization (EDI) - E-Cell MK-3Pharm Stack User Manual

E-cell* mk-3pharm stack, Description and use, Typical application

Fact Sheet

Find a contact near you by visiting www.ge.com/water and clicking on “Contact Us” .

* Trademark of General Electric Company; may be registered in one or more countries.

©2012, General Electric Company. All rights reserved.

FS1623EN.doc Jun-12

E-Cell* MK-3Pharm Stack

Electrodeionization (EDI) Stacks for Pharmaceutical Applications

E-Cell *MK-3Pharm is designed to:

Provide Ultrapure Water for Pharmaceutical

applications.

Produce Mixed Bed quality water on a

continuous basis.

Require no caustic or acid for regeneration of

mixed bed resin within the stack.

Be leak free, guaranteed

Eliminate brine injection and concentrate

recirculation, simplifying system design.

Description and Use

MK-3Pharm E-Cell stacks are electrodeionization

(EDI) stacks which use electrical current to deion-

ize and polish reverse osmosis (RO) permeate wa-

ter. The product water for the MK-3Pharm is at

greater than USP quality levels required in today’s

Pharmaceutical applications.

Typical Application

Pharmaceutical

Laboratory

Quality Assurance

CE, UL & CSA marked

Manufactured in a ISO 9001:2000 facility

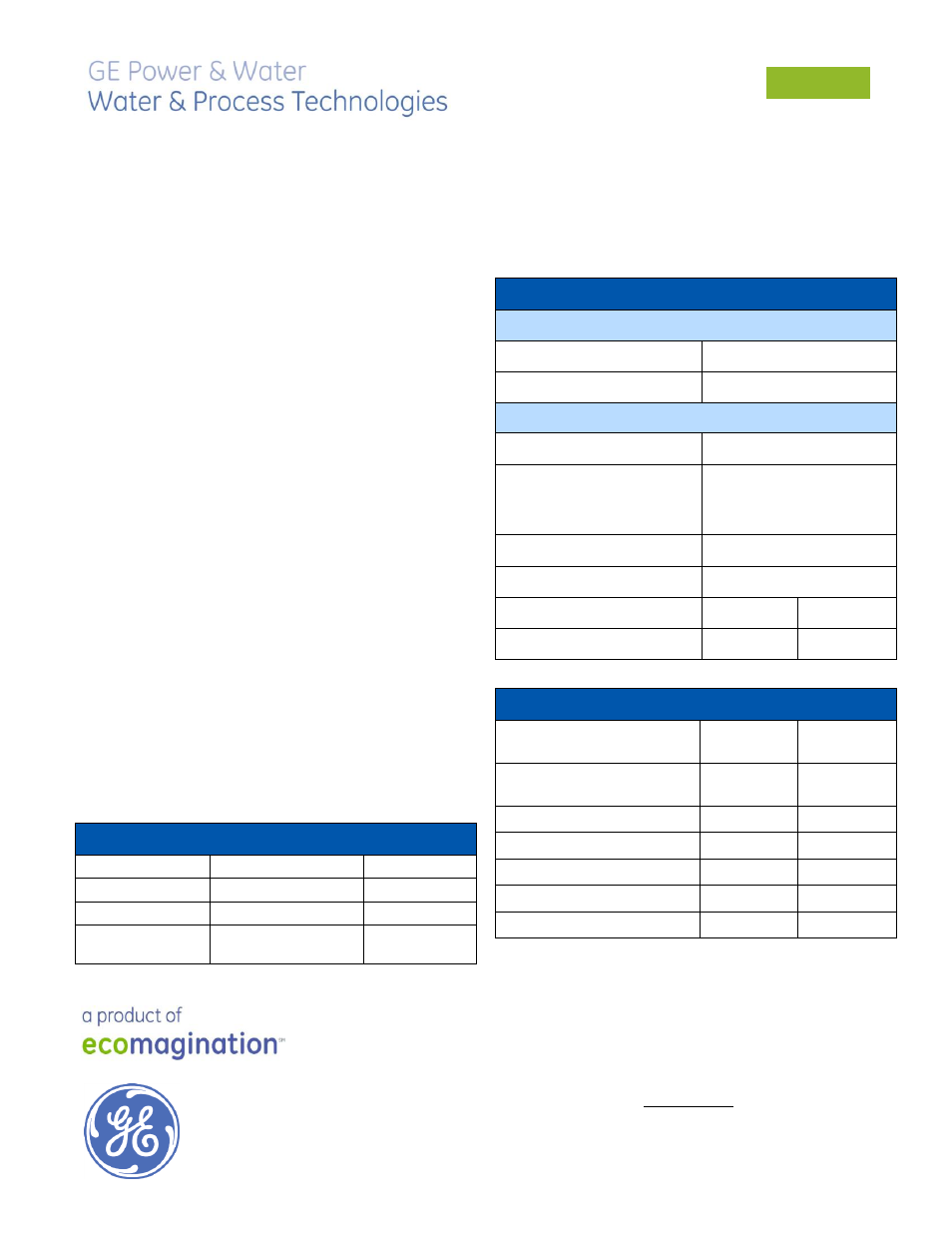

MK-3Pharm Stack Specifications

Nominal Flow

4.1 m

3

/hr

18.0 gpm

Flow Rate Range

1.6 – 4.5 m

3

/hr

7.0 – 20.0 gpm

Shipping Weight

92 kg

202 lbs

Dimensions

(width x height x depth)

30 cm x 61 cm x 48 cm 12” x 24” x 19”

Typical Performance

Product Quality

Resistivity

> 10 MOhm-cm

TOC (as C)

< 500 ppb

Operating Parameters

Recovery

Up to 95%

Concentrate Flow

Counter current vs.

Product Flow - Standard

Co-current vs. Product Flow –

when fed by double pass RO

Voltage

0 – 300 VDC

Amperage

0 – 5.2 ADC

Inlet Pressure

4.1 – 6.9 bar

60 – 100 psi

Pressure Drop at Nominal Flow

1.4 – 2.4 bar

20 – 35 psi

Maximum Feed Water Specifications

Feed Water - Total Exchangea-

ble Anions (TEA as CaCO

3

)

<25 mg/l

<25 ppm

Feed Water – Conductivity,

NaHCO

3

equivalent

< 43 μS/cm

< 43 μS/cm

Temperature

4.4 – 38˚C

40 – 100˚F

Total Hardness (as CaCO

3

)

< 1.0 mg/l

< 1.0 ppm

Silica (SiO

2

)

< 1.0 mg/l

< 1.0 ppm

Total Organic Carbon (TOC as C) < 0.5 mg/l

< 0.5 ppm

Total Chlorine

< 0.05 mg/l

< 0.05 ppm

Actual performance may vary depending on site conditions.

Reference E-Calc projection software to verify actual performance.

Patents pending.