GE P&W Service Deionization (SDI) - MegaFlo User Manual

Megaflo, Portable exchange deionization vessel, Benefits

Fact Sheet

Find a contact near you by visiting www.ge.com/water and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2010, General Electric Company. All rights reserved.

FS1116EN.doc Apr-10

MegaFlo*

Portable Exchange Deionization Vessel

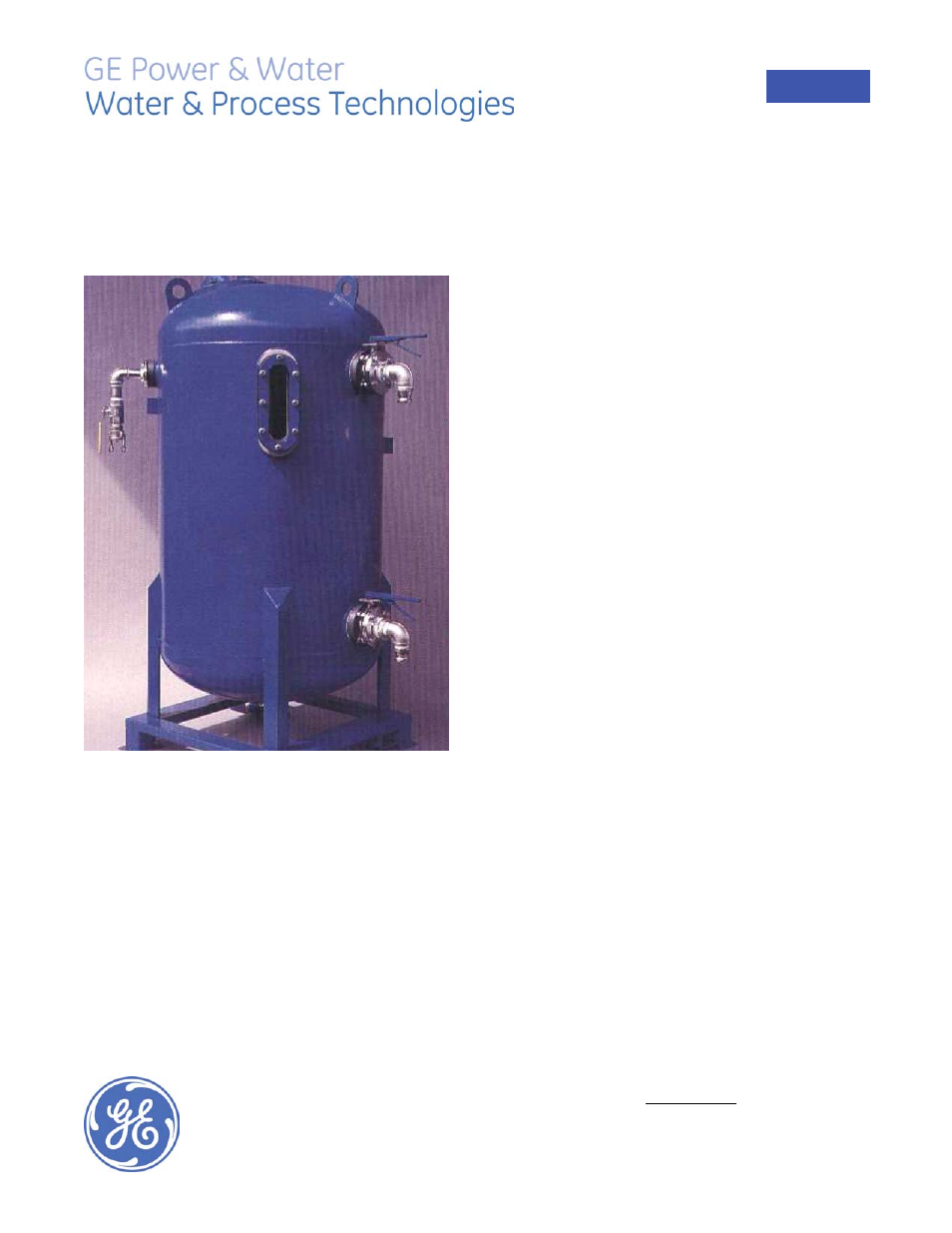

Figure 1: MegaFlo* Portable Exchange Deionization

Vessel

Benefits

• Improved water quality

• Exhausted vessels are exchanged and regener-

ated off-site by GE - eliminating down time

• Customers no longer need to use operations

personnel for regeneration activities

• Increased safety by eliminating chemical deliv-

ery, storage and handling

• Regenerated at GE Facilities

Equipment Specifications

Vessel

• Carbon Steel construction

• 150 PSI ASME Code stamped

• 3/16" (5 mm) thick white rubber lined with

manway in vessel dome

Sight Glass

• At media height for inspections

Internals

• Electropolished 316 Stainless

• Steel wedge header lateral

Inlet/Outlets

• 2" to 4" (5 to 10 cm) connections with butterfly

valves. Schedule 80 PVC external piping

(Stainless Steel, Polypropylene or PVDF on re-

quest)

Media

43 ft

3

(1 m

3

) per vessel of either:

• Mixed Bed Ion Exchange Resin

• Separate Bed Cation and Anion Resin

• Activated Carbon Media

Flow Rate

• 25 to 150 gpm (0.1 to 0.6 m

3

/h)

Dimensions

• 42" (1 m) diameter by 54" (1.4 m)

Contact Us

For more information on MegaFlo contact us at

1-800-446-8004, visit our website or contact your

GE representative.

Note: Product line manufactured by GE Mobile Water, Inc, 5900

Silver Creek Valley Rd, San Jose, CA 95138.