GE P&W Spiral Wound Membranes - SE Series User Manual

Se series, Fact sheet, Table 1: element specification

Fact Sheet

Find a contact near you by visiting www.gewater.com and clicking on “Contact Us” .

* Trademark of General Electric Company; may be registered in one or more countries.

©2013, General Electric Company. All rights reserved.

AM-FSpwSESeries_EN.doc Nov-13

SE Series

Industrial High Rejection Brackish Water RO Elements

The S-Series family of proprietary thin-film reverse

osmosis membrane elements is characterized by

high sodium chloride rejection and a smooth, foul-

ing-resistant membrane surface.

SE High Rejection Brackish Water Elements are

used for brackish water desalination and process

stream concentration.

The SE elements feature either a fiberglass or a pa-

tented Durasan* cage outer wrap, 30mil or 50mil

spacer and polysulfone or Noryl plastic parts.

Table 1: Element Specification

Membrane

S-Series, Thin-Film Membrane (TFM*)

Model

Average

permeate flow

gpd (m3/day)

1,2

Average NaCl

rejection

1,2

Minimum

NaCl

rejection

1,2

SE2540F30

550 (2.1)

98.5%

97.5%

SE2540F50

370 (1.4)

98.5%

97.5%

SE8040C30

8,300 (31.4)

98.5%

97.5%

1

Average salt rejection after 24 hours operation. Individual flow rate may vary

±25%.

2

Testing conditions: 2,000ppm NaCl solution at 425psi (2,930kPa) operating pres-

sure, 77°F (25°C), pH6.5 and 15% recovery.

Model

Spacer

mil (mm)

Active area

ft

2

(m

2

)

Outer wrap

Part

number

SE2540F30

30 (0.76)

25 (2.3)

Fiberglass

1207431

SE2540F50

50 (1.27)

17 (1.6)

Fiberglass

1207427

SE8040C30

30 (0.76)

378 (35.1)

Cage

1207488

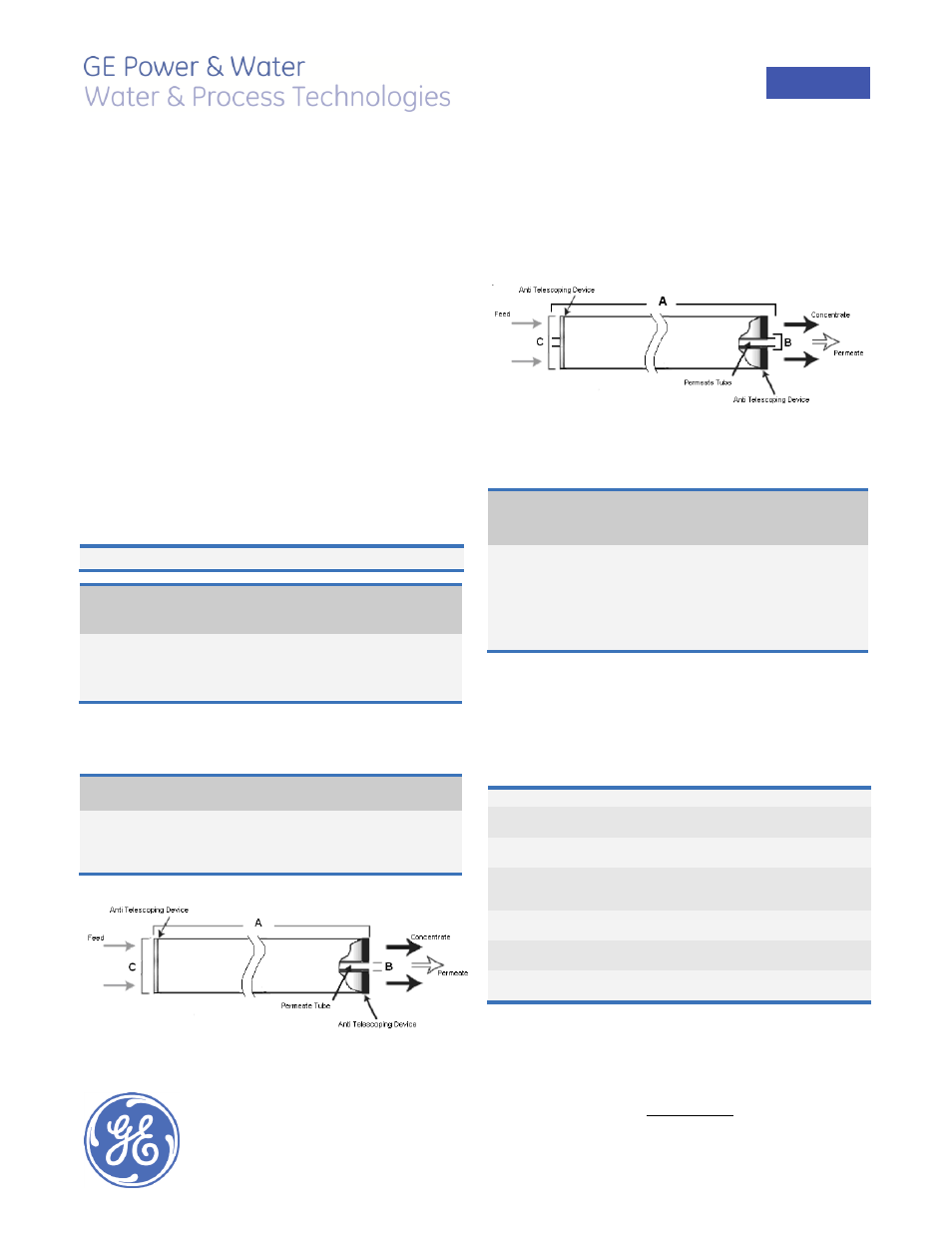

Figure 1: Element Dimensions Diagram (Female)

Figure 2: Element Dimensions Diagram (Male)

Table 2: Dimensions and Weight

Model

1

Dimensions, inches (cm)

Boxed

A

B

2

C

3

Weight

lbs (kg)

SE2540F30

40.0

(101.6)

0.75

(1.9) OD

2.4

(6.1)

4

(1.8)

SE2540F50

40.0

(101.6)

0.75

(1.9) OD

2.4

(6.1)

4

(1.8)

SE8040C30

40.0

(101.6)

1.125

(2.86)

7.9

(20.1)

29

(13.2)

1

These elements are dried then bagged before shipping.

2

Internal diameter unless specified OD (outside diameter).

3

The element diameter (dimension C) is designed for optimum performance in GE

pressure vessels. Other pressure vessel dimension and tolerance may result in

excessive bypass and loss of capacity.

Table 3: Operating and CIP Parameters

Typical Operating Flux

5-20 GFD (8-34 LMH)

Maximum Operating Pressure

600psi (4,137kPa) if T < 95°F (35°C)

435psi (3,000kPa) if T > 95°F (35°C)

Maximum Temperature

Continuous Operation: 122°F (50°C)

Clean-In-Place (CIP): 122°F (50°C)

pH Range

Optimum rejection Range 5.5-7.0

Continuous Operation: 2.0-10.0

Clean-In-Place (CIP): 1.0-10.5

Maxime Pressure Drop

Over an element: 15psi (103kPa)

Per housing: 60psi (414kPa)

Chlorine Tolerance

500+ ppm-hours,

dechlorination recommended

Feedwater

NTU < 1

SDI < 5