Results – GE P&W FuelSolv FS3954: Controls Ash-Clogging in an Incinerator Boiler User Manual

Page 2

Page 2

Case Study

In the test, two injection points were placed at the

outlet of the furnace in the first riser stage of the

boiler (smoke temperature 850°C/1560°F, the mini-

mum temperature for injection being 760°C/

1400°F).

The test was conducted from December 2002 to

May 2003.

Results

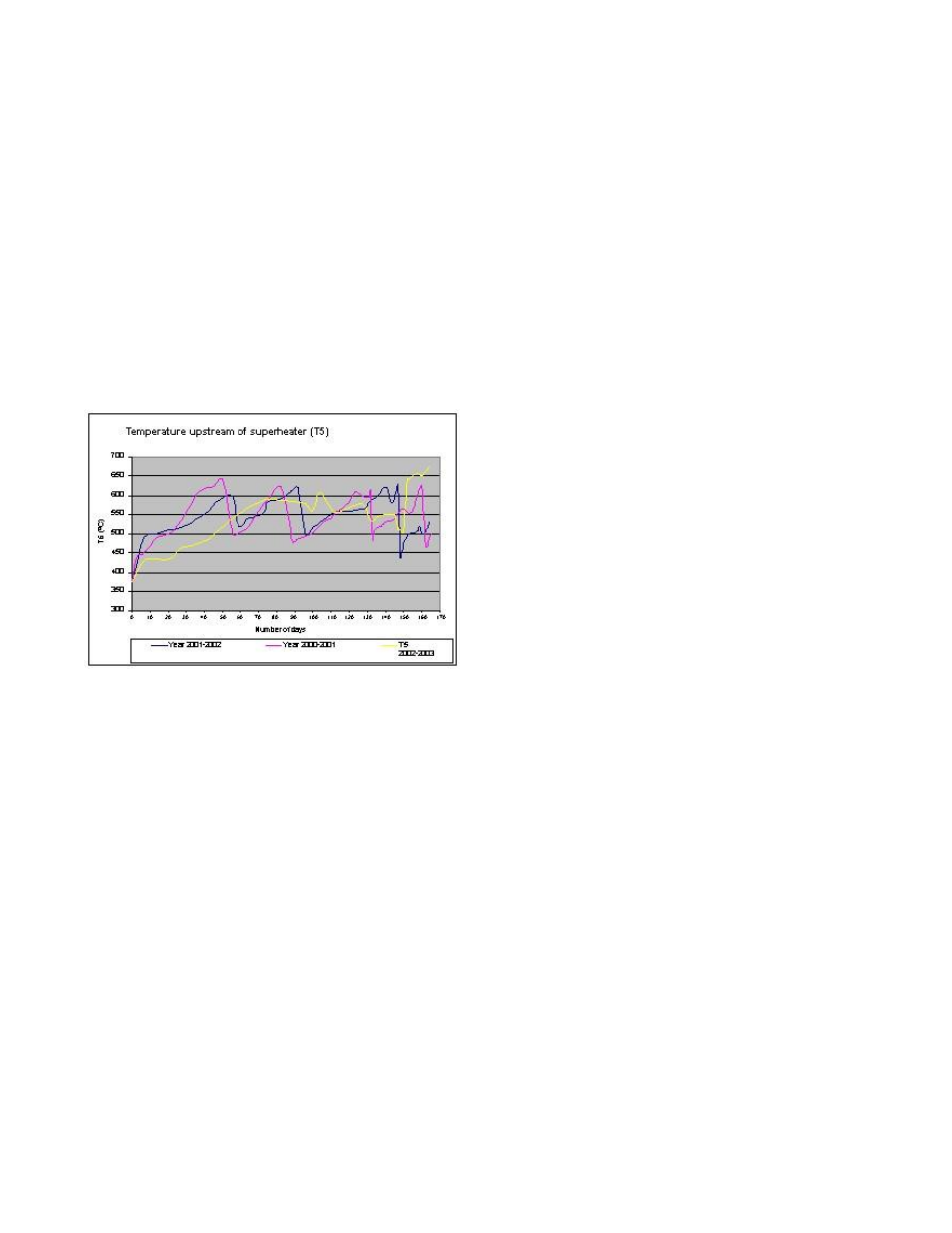

The critical parameter for validating the test is the

temperature of the smoke (T5) upstream of the

superheaters. That temperature enables the opera-

tor to determine the shutdown for cleaning of the

installation. (650°C/1200°F).

Thanks to our technology, the client achieved its

primary goal: no shutdown between the two sched-

uled annual technical maintenances.

Achieving that goal enabled the operator to make

significant gains:

Fulfill electricity-supply commitments with EDF

No additional cost from outside treatments of

household waste

Reduction in operating cost

- Pleated Filters - Flotrex GF Capsule Pleated Filters (2 pages)

- ABMet for Selenium Removal (3 pages)

- Spiral Wound Membranes - Dairy HWS (3 pages)

- Tonkaflo - MUNI Series 60 Hz (2 pages)

- Service Deionization (SDI) - TurboFlo DI Vessels (2 pages)

- Spiral Wound Membranes - Duratherm EXL Series (4 pages)

- E-Series L (2 pages)

- Spiral Wound Membranes - OSMO BEV NF Series (2 pages)

- SeaPRO-E-36 - 500 m3_day (92 gpm) (2 pages)

- ZeeWeed 1000 Hollow-Fiber Membranes (1 page)

- Spiral Wound Membranes - JX Series (1 page)

- E-Series Reverse Osmosis - EZ-4 Kit 50 Hz (2 pages)

- E-Series Reverse Osmosis - E2 60 Hz (2 pages)

- Hydrogen Sulfide Scavengers - CorTrol OS7785 (2 pages)

- PRO LA Series 50 Hz (2 pages)

- Spiral Wound Membranes - Certified Elements (1 page)

- Tonkaflo - GE BEV Series (2 pages)

- Spiral Wound Membranes - AG Series (2 pages)

- CoalPlus - DusTreat DC9140 (1 page)

- CoalPlus - DusTreat DC9140E (2 pages)

- FuelSolv - Opportunity Coal Slag Control at Lakeland McIntosh Unit #3 (10 pages)

- Spiral Wound Membranes - Dairy JX Series (1 page)

- CoalPlus - DusTreat DC9163E (1 page)

- PowerTreat AD9067 (2 pages)

- Pleated Filters - Memtrex HFE-T - Polyester PTFE (2 pages)

- Tonkaflo - PROPAK NA Series (2 pages)

- Pleated Filters - XPleat PES Pleated Filters (2 pages)

- Mobile Water Treatment Systems - Mobile Multi-Media Filtration Trailer (2 pages)

- Spiral Wound Membranes - CK Series (1 page)

- Spiral Wound Membranes - GK Series (1 page)

- FuelSolv - Slag Control Treatment Program at a Southeastern Utility (10 pages)

- Mobile Water Treatment Systems - MobileFlow (2 pages)

- SeaPRO Series 50 Hz 45,000 ppm NaCl 100-300 m3_day (2 pages)

- Spiral Wound Membranes - Pharma Elements (1 page)

- Ultrapure and Drinking Water TOC Analyzers - Sievers 860 Laboratory TOC Analyzer & GE Autosampler RT12 (5 pages)

- PowerTreat - Company Overview Facts (2 pages)

- Mobile Water Treatment Systems - Standard Resin Regeneration Services (2 pages)

- Pleated Filters - Flotrex AP Capsule with Polypropylene Microfiber Media, Nominal (2 pages)

- PRO E-Cell (2 pages)

- Spiral Wound Membranes - AK Series (2 pages)

- E-Series Reverse Osmosis - E4 60 Hz (2 pages)

- SeaPRO-E-72 - 1000 m3_day (184 gpm) (2 pages)

- Pleated Filters - Memtrex PC Pleated Filters (2 pages)

- Pleated Filters - Memtrex PM Capsule Filters with Hydrophobic Polypropylene Membrane, Absolute (2 pages)

- Spiral Wound Membranes - OSMO BEV Reverse Osmosis Series (2 pages)