GE P&W Spiral Wound Membranes - Dairy PW Series User Manual

Dairy pw series, Ultrafiltration – protein concentration, Fact sheet

Find a contact near you by visiting www.gewater.com and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2013, General Electric Company. All rights reserved.

FSsmDairyPWSeries_EN.doc Nov-13

Fact Sheet

Dairy PW Series

Ultrafiltration – Protein Concentration

The Dairy PW Series family of polyethersulfone ul-

trafiltration membrane elements are characterized

by a 30,000 molecular weight cut-off. Dairy PW El-

ements are typically used for protein concentrate

up to 20% either from milk and sweet whey (not

suitable for acid whey).

These elements feature a Durasan* Cage patented

outer wrap, a selection of feed spacers, and polysul-

fone parts.

The Dairy PW elements comply with:

FDA Regulations relevant sections of 21CFR

EU Framework 1935/2004/EC

Table 1: Element Specification

Membrane

P-Series, Polyethersulfone

Model

Spacer mil

(mm)

Active area

ft

2

(m

2

)

Outer wrap

Part

number

DAIRY PW3838C30

30 (0.76)

66 (6.1)

Cage

1228024

DAIRY PW3838C50

50 (1.27)

51 (4.7)

Cage

1229303

DAIRY PW5838C50

50 (1.27)

127 (11.8)

Cage

1207391

DAIRY PW6338C30

30 (0.76)

212 (19.7)

Cage

1207392

DAIRY PW6338C50

50 (1.27)

169 (15.7)

Cage

1207393

DAIRY PW6338C65

65 (1.65)

132 (12.6)

Cage

1223985

DAIRY PW8038C30

30 (0.76)

330 (30.6)

Cage

1230789

DAIRY PW8038C50

50 (1.27)

254 (23.6)

Cage

1230680

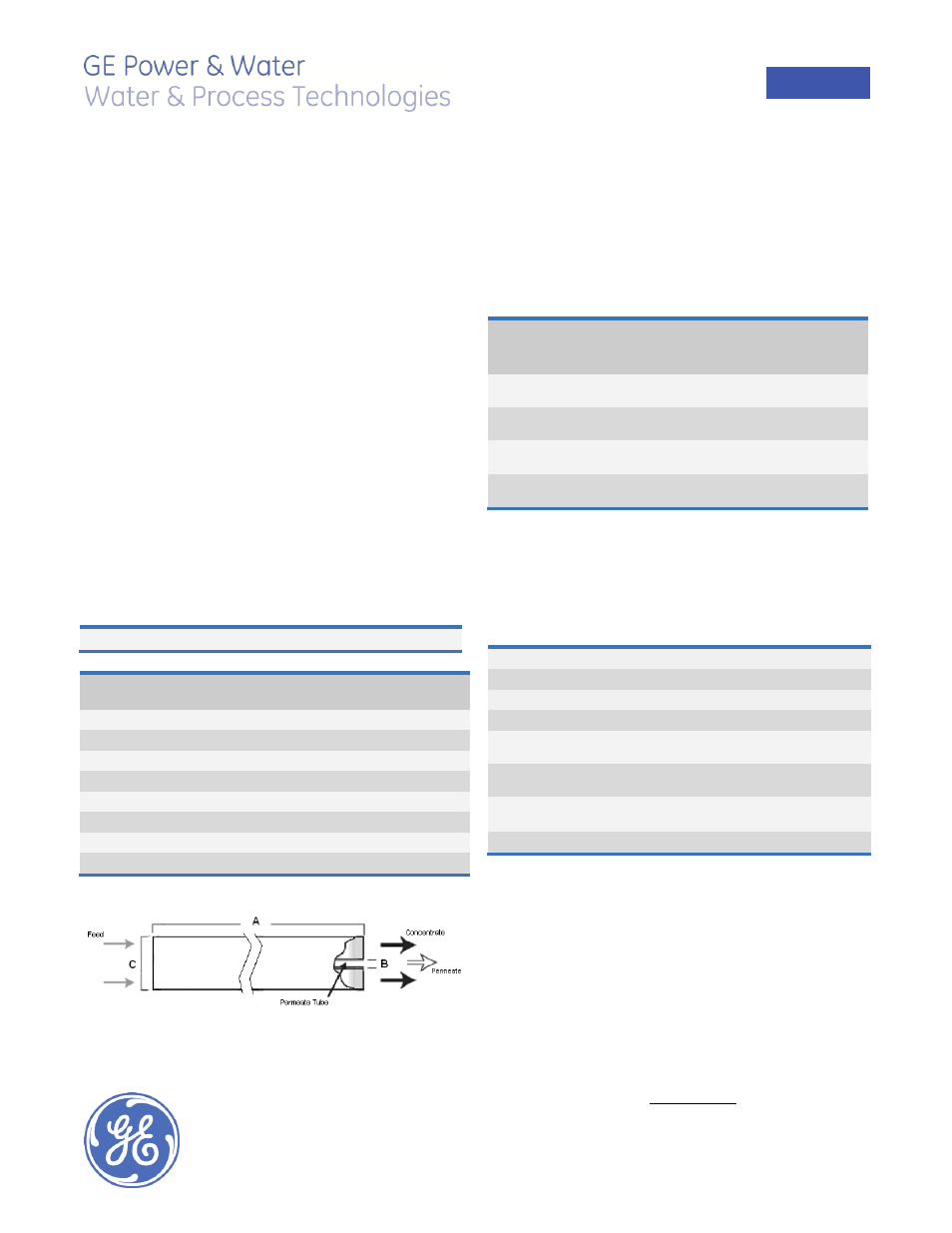

Figure 1: Element Dimensions Diagram

Table 2: Dimensions and Weight

Model

1

Dimensions, inches (cm)

Boxed

A

B

2

C

3

Weight

lbs (kg)

DAIRY PW3838

38.0

(96.5)

0.833

(2.12)

3.79

(9.6)

7

(3.2)

DAIRY PW5838

38.0

(96.5)

1.138

(2.89)

5.71

(14.5)

18

(8.2)

DAIRY PW6338

38.0

(96.5)

1.138

(2.89)

6.34

(16.1)

18

(8.2)

DAIRY PW8038

38.0

(96.5)

1.125

(2.86)

7.91

(20.1)

29

(13.2)

1

These elements are bagged dry before shipping.

2

Internal diameter unless specified OD (outside diameter).

3

The element diameter (dimension C) is designed for optimum performance in GE

pressure vessels. Other pressure vessel dimension and tolerance may result in

excessive bypass and loss of capacity.

Table 4: Operating and CIP parameters

Typical Operating Pressure

80-135 psig (555 – 931 kPa)

Typical Operating Flux

10-25GFD (15-40LMH)

Clean Water Flux (CWF)

1

59GFD (100LMH) @ 30psi and 50°C

Maximum Operating Pressure

200 psig (1,379 kPa)

Maximum Temperature

Continuous operation: 122°F (50°C)

Clean In Place (CIP): 122°F (50°C)

pH Range

Continuous operation: 4.0-11.0,

Clean In Place (CIP): 2.0-11.5

Maximum Pressure Drop

Over an element: 12 psig (83 kPa)

Per housing: 50 psig (345 kPa)

Chlorine Tolerance

5,000+ ppm-days

1

Clean water flux (CWF) is the rate of water permeability through the membrane

after cleaning (CIP) at reproducible temperature and pressure. It is important to

monitor CWF after each cleaning cycle to determine if the system is being

cleaned effectively. CWF can vary ± 25%.