Integrity testing, Additional information – GE P&W Pleated Filters - Memtrex HFE - Halar PTFE User Manual

Page 2

Page 2

Fact Sheet

Table 2: Dimensions

Filter

model

Nominal O.D.

Nominal I.D.

MHFE85

MHFE91

MHFE92

MHFE94

MHFE01

2.75” (70mm)

2.75” (70mm)

2.75” (70mm)

2.75” (70mm)

2.75” (70mm)

1.25” (31mm)

1.25” (31mm)

1.25” (31mm)

1.25” (31mm)

1.25” (31mm)

Table 3: Operational Limits

Maximum forward differential pressure

Maximum reverse differential pressure

Maximum operating temperature

60 psi (4.14 bar) at 70°F (21.1°C)

30 psi (2.07 bar) at 70°F (21.1 C)

205ºF (96.1ºC) at 25 psid (1.7 bar)

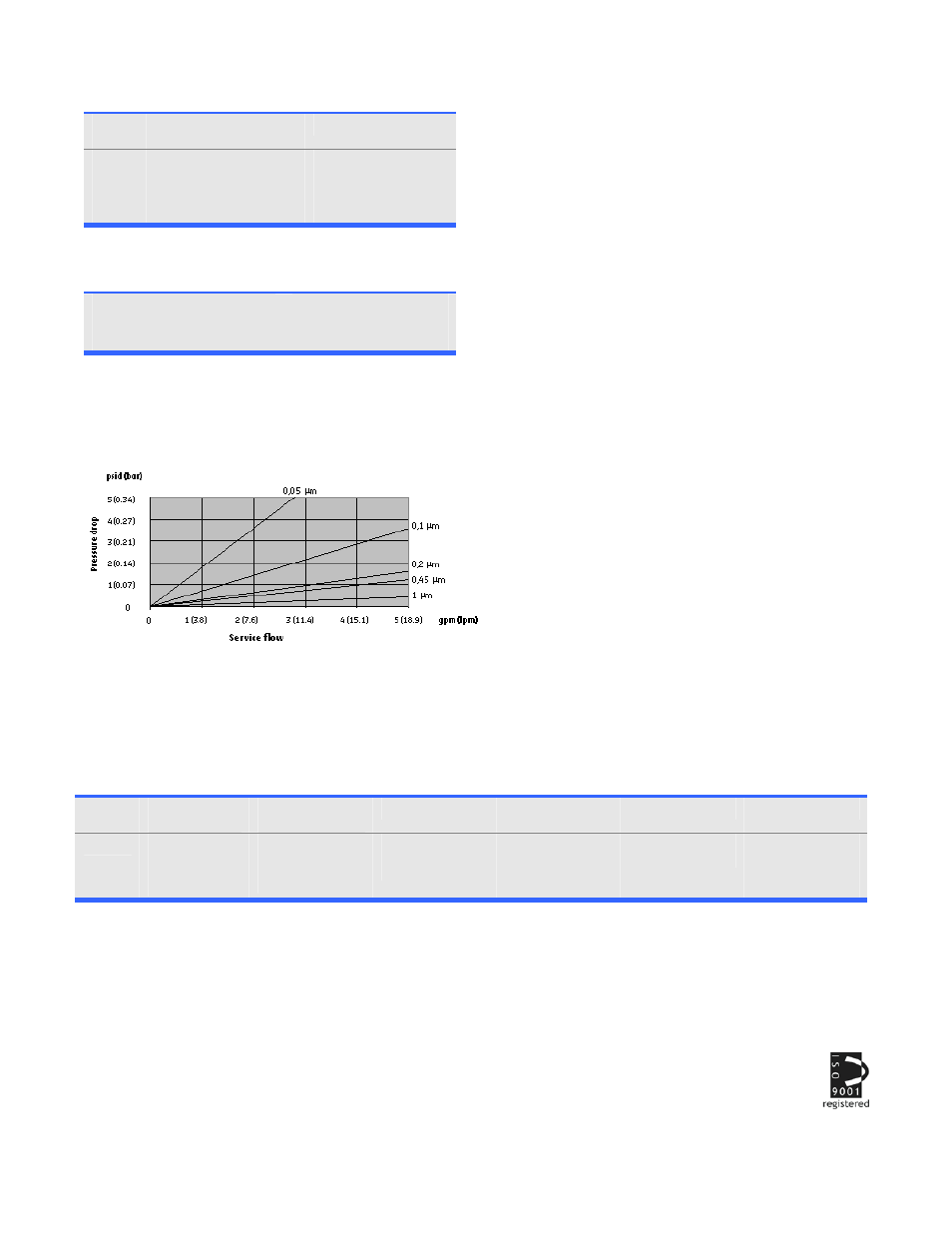

Table 4: Flow Performance in CleanWater

1

1

Data based on 10” length filter

Integrity Testing

• 0.05 µm

≤ 5 cc / min at 40 psig (2.76 bar)

• 0.1 µm

≤ 5 cc / min at 40 psig (2.76 bar)

• 0.2 µm

≤ 5 cc / min at 30 psig (2.07 bar)

• 0.45 µm ≤ 5 cc / min at 20 psig (1.38 bar)

• 1 µm

≤ 5 cc / min at 15 psig (1.38 bar)

Additional Information

• Memtrex HFE filters may be sanitized with

compatible chemical agents. The filters must

not be autoclaved or steam sterilized.

• GE certifies that the material contained in its

Memtrex HFE pleated filters meet U.S. FDA

requirements for food contact under the ap-

plicable regulations in 21 CFR. For further in-

formation, contact GE technical services.

Memtrex HFE filters meet the test criteria for

USP class VI-121°C Plastics.

• Aqueous extracts from Memtrex HFE filters

contain less that 0.25 EU/ml. The filters typi-

cally exhibit low levels of non-volatile residues.

• GE filter cartridges are designed and manu-

factured for resistance to a wide range of

chemical solutions. Conditions will vary with

each application and users should carefully

verify chemical compatibility. Please contact

your GE distributor for more information.

Table 5 provides additional ordering information. Table 5: Ordering Information

Type

Absolute Micron

Rating

Nominal cartridge

Length

End #1 Adapter

End #2 Adapter

Elastomer material

Product Grade

MHFE

85 = 0.05 µm

91 = 0.1 µm

92 = 0.2 µm

94 = 0.45 µm

1 = 10 in (25 cm)

2 = 20 in (51 cm)

3 = 30 in (76 cm)

4 = 40 in (102 cm)

A = Open End Gasket

E = 222 O-Ring

F = 226 O-Ring

A = Open End Gasket

E = Closed End Cap

H = Fin Adapter

T = Teflon² Encapsu-

lated Viton²

E = Electronic grade

rinse

Pre Wet = Rinsed and

packed wet

²Teflon and Viton are a registered trademark of DuPont.