Table 2: dimensions and weight, Table 3: operating and cip parameters – GE P&W Spiral Wound Membranes - AG Series User Manual

Page 2

Page 2

FS1262EN

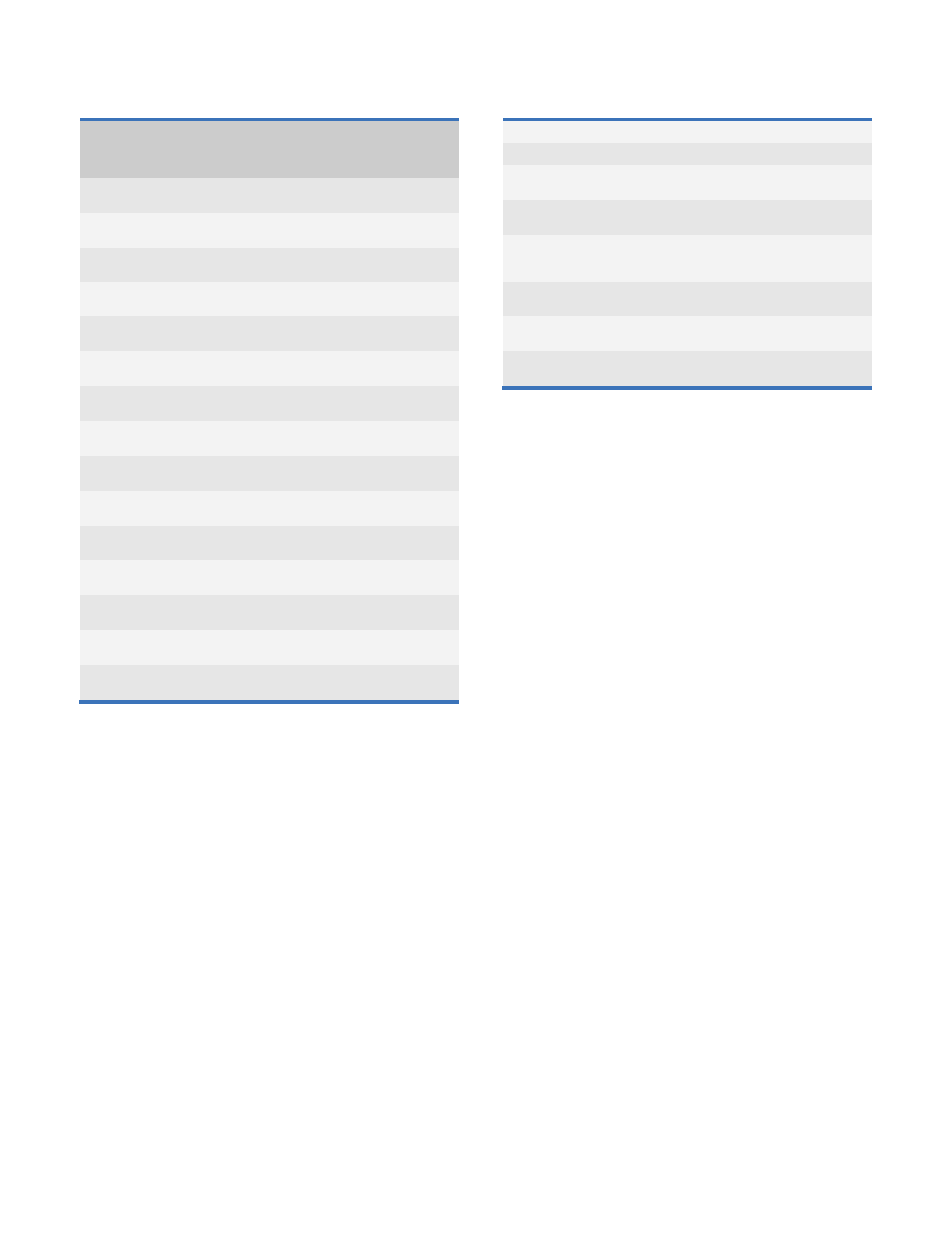

Table 2: Dimensions and Weight

Model

1

Dimensions, inches (cm)

Boxed

A

B

2

C

3

Weight

lbs (kg)

AG2540TM

40.0

(101.6)

0.75

(1.90) OD

2.4

(6.1)

5

(2.3)

AG4025T

25.0

(63.5)

0.625

(1.59)

3.9

(9.9)

5

(2.3)

AG4026F

26.0

(66.7)

0.625

(1.59)

3.9

(9.9)

6

(2.7)

AG4040C

40.0

(101.6)

0.625

(1.59)

3.9

(9.9)

8

(3.5)

AG4040FM

40.0

(101.6)

0.75

(1.90) OD

3.9

(9.9)

8

(3.5)

AG4040FM WET

40.0

(101.6)

0.75

(1.90) OD

3.9

(9.9)

8

(3.5)

AG4040TM

40.0

(101.6)

0.75

(1.90) OD

3.9

(9.9)

8

(3.5)

AG8040C

40.0

(101.6)

1.125

(2.86)

7.9

(20.1)

32

(14.5)

AG8040F

40.0

(101.6)

1.125

(2.86)

7.9

(20.1)

32

(14.5)

AG8040F WET

40.0

(101.6)

1.125

(2.86)

7.9

(20.1)

35

(16)

AG8040F 400

40.0

(101.6)

1.125

(2.86)

7.9

(20.1)

32

(14.5)

AG8040F 400 WET

40.0

(101.6)

1.125

(2.86)

7.9

(20.1)

35

(16)

AG8040N

40.0

(101.6)

1.125

(2.86)

7.9

(20.1)

32

(14.5)

AG8040N 400

40.0

(101.6)

1.125

(2.86)

7.9

(20.1)

32

(14.5)

AG8340F 400

40.0

(101.6)

1.125

(2.86)

8.3

(21.1)

42

(19.1)

1

These elements are bagged dried, unless specified WET, before shipping.

2

Internal diameter unless specified OD (outside diameter).

3

The element diameter (dimension C) is designed for optimum performance in

GE pressure vessels. Other pressure vessel dimension and tolerance may

result in excessive bypass and loss of capacity.

Table 3: Operating and CIP parameters

Typical Operating Pressure

200 psi (1,379 kPa)

Typical Operating Flux

10-20GFD (15-35LMH)

Maximum Operating Pressure

Tape 450 psi (3,103 kPa)

Other outerwrap: 600 psi (4,137 kPa)

Maximum Temperature

Continuous operation: 122°F (50°C)

Clean-In-Place (CIP): 122°F (50°C)

pH Range

Optimum rejection: 7.0-7.5,

Continuous operation: 4.0-11.0,

Clean-In-Place (CIP): 2.0-11.5

Maximum Pressure Drop

Over an element: 12 psi (83 kPa)

Per housing: 50 psi (345 kPa)

Chlorine Tolerance

1,000+ ppm-hours,

Dechlorination recommended

Feedwater

NTU < 1

SDI < 5