Hot water sanitization recommendations – GE P&W Spiral Wound Membranes - Duratherm EXL Series User Manual

Page 2

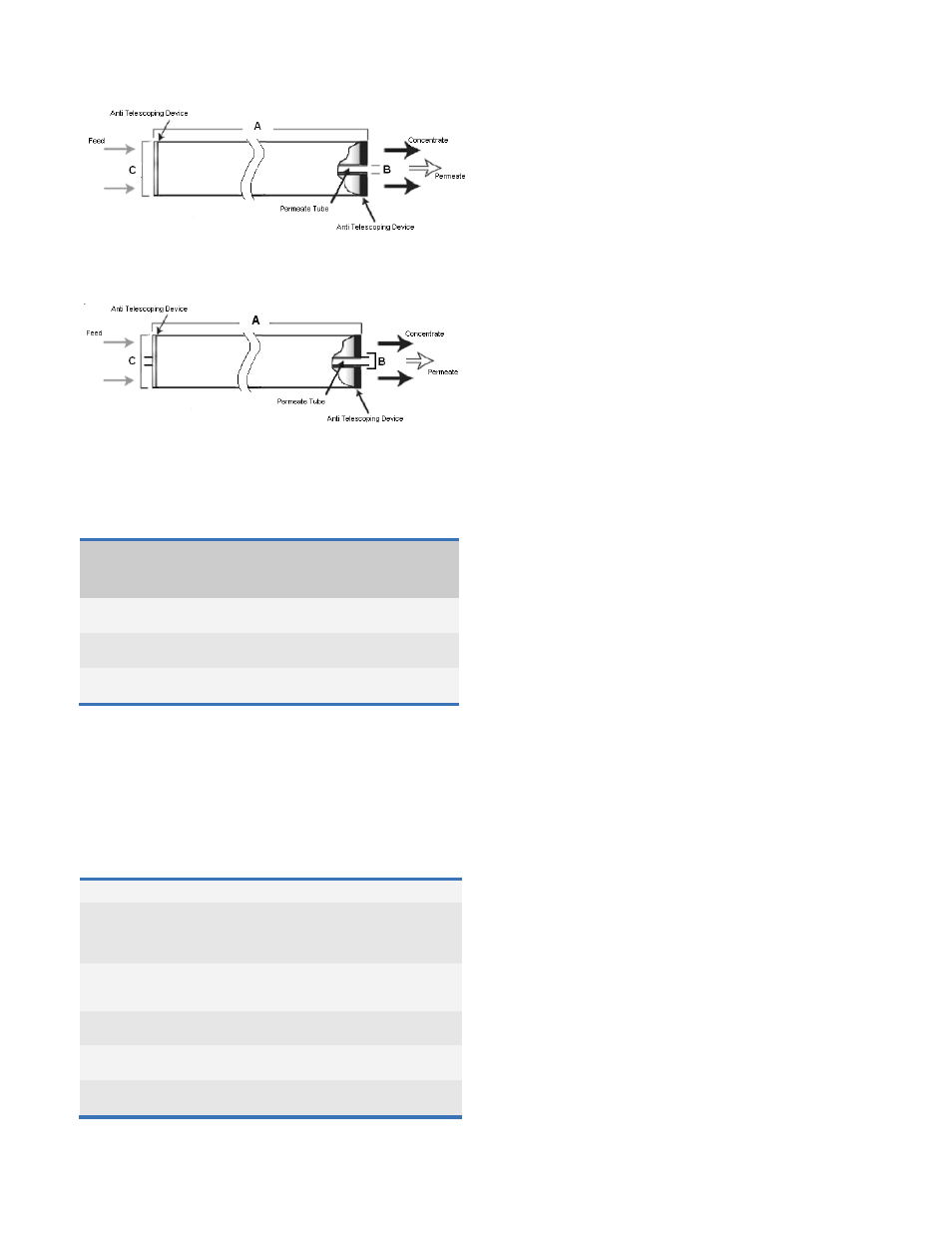

Figure 1A: Element Dimensions Diagram – Female

Figure 1B: Element Dimensions Diagram – Male

Table 3: Dimensions and Weight

Model²

Dimensions, inches (cm)

Boxed

A

B

1

C

3

Weight

lbs (kg)

XX 2540

40.0

(101.6)

0.75

(1.91)

2.43

(6.17)

4

(1.8)

XX 4040

40.0

(101.6)

0.625

(1.59)

3.9

(9.9)

9

(4.1)

XX 8040

40.0

(101.6)

1.125

(2.86)

7.9

(20.1)

29

(13.2)

1

Internal diameter.

² These elements are dried then bagged before shipping.

3

The element diameter (dimension C) is designed for optimum performance in GE

pressure vessels. Others pressure vessel dimension and tolerance may result in

excessive bypass and loss of capacity.

Table 4: Operating and CIP parameters

Do not exceed 20 GFD (33 LMH) or 2,000 Wagner units

under any circumstance.

Typical Operating Pressure

Figures 9 & 10

Maximum Operating Pressure 1,200 psi (8,273 kPa)

600 psi (4,137 kPa)

400 psi (2,758 kPa)

Hot Water Sanitizing

32 – 77°F (0 – 25°C)

78 – 122°F (26 – 50°C)

123 – 158°F (51 – 70°C)

158 – 194°F (70 – 90°C)

Maximum Temperature

Continuous Operation: 177°F (70°C)

Clean-In-Place (CIP): 104°F (40°C)

Hot Water Sanitizing: 194°F (90°C)

pH range

Continuous Operation: 3 – 9

clean-In- Place (CIP): 2 – 10.5

Chlorine Tolerance

500 ppm hours

dechlorination recommended

Feedwater

NTU < 1

SDI < 5

Hot Water Sanitization

Recommendations

For optimal performance, Duratherm EXL elements

should always be cleaned using approved CIP pro-

cedures and flushed with fouling free water before

the sanitization process. Feed pressure during sani-

tization should not exceed 40psi (275kPa) and the

crossflow should not incur a pressure drop greater

than 2psi (14kPa) per element. Heating rate to sani-

tizing temperature and cool down should not be

faster than 5°C (9ºF)/minute. Maximum sanitization

temperature is 90°C (194ºF).

Loss of permeate flow after repeated

90ºC (194ºF) sanitization cycles

It is almost impossible to exactly predict the per-

centage of permeate flow rate lost from the high

temperature sanitations, which among other fac-

tors depends on:

• The rate of temperature increase and decrease.

• The presence of other species like organics, ion-

ic and metallic compounds that could locally

decrease or increase the temperature at the

surface of the membrane.

• The feed flow rate and specifically the heat

transfer rate to the membrane surface.

• The thickness and geometry of the feed spacer

used.

At optimum conditions measured in controlled envi-

ronment with deionized water, between 30% and

50% of the original permeate flow rate was lost be-

fore the element performance had stabilized after

repeated heat treatments (over 90% of this flow

reduction occurred during the first heat treatment).

With the loss of permeate flow rate, the salt rejec-

tion increases. The rate of cooling and heating was

not more than 5°C (9ºF) per minute, and the differ-

ential pressure drop per element did not exceed 2

psi.

Pilot testing based on the criteria noted above will

give the best operating parameters for any specific

application.

Page 2

Fact Sheet