Simple is best, Experience matters, Guaranteed performance is a must – GE P&W ABMet for Selenium Removal User Manual

Page 2: Innovative technology means, What can abm, Remove, Be used, What are the process constraints, What flow rates can be treated with abmet

Simple is best

ABMet meets stringent effluent

selenium requirements as well as

most effluent BOD and suspended

solids requirements in one simple

step. No post-treatment required.

Low labor cost – Automatic operation,

remote monitoring and diagnostics with

GE’s Insight* and a one-step process

means that optimal performance

is achieved with minimum operator

resources (less than 1 FTE).

Low consumables cost – GE’s single

nutrient is an all-in-one source

of carbon, nitrogen, phosphorus

and micro-nutrients. One injection

point + one chemical system + one

consumable = low operating costs

Superior Reliability – Simple

gravity flow biofilter design and no

integration of multiple unit operations

means no downtime. In the power

industry, availability is critical.

ABMet can meet the industry’s

99.9% availability requirement.

Experience matters

From being a breakthrough technology

in the late 1990s to being the

technology of choice for the mining

and power industries today, selenium

removal is in the ABMet DNA.

Trust – With 17 years of biological

selenium removal development,

more than 10 operating plants

and several projects under

development, ABMet is a trusted

technology for selenium removal.

Guaranteed

performance is a must

ABMet systems are backed by a

performance guarantee that manages

the risk of non-compliance and allows

clients to focus on their core business.

Manage risk – Guaranteed effluent total

selenium concentration down to below

5 ppb-total selenium.Guaranteed effluent

BOD and TSS concentrations down to

30 and 35 ppm respectively without

the need for post-treatment.

Guaranteed performance down to

a water temperature of 5°C without

the need for pre-heating.

Focus on the core business – ABMet

has a proven track record getting

the job done, enabling our clients to

employ their resources more efficiently

in their core business activities.

Innovative

technology means…

Fast and guaranteed startup – GE’s

seed culture product consists of

specialized bacteria strains optimally

selected for treatment of selenium

laden waters. One-time seeding only.

Optimal performance – GE’s

innovative biofilter design along with

a carefully selected seed culture

and specifically formulated nutrient,

optimize the environment needed

for biological removal of selenium.

Selenium REMOVAL solution – ABMet

biofilters are designed to capture

and remove selenium directly,

NOT transform it and transfer it to

downstream processes for removal.

GE is in your corner – GE

innovation and commitment to

performance is working for you.

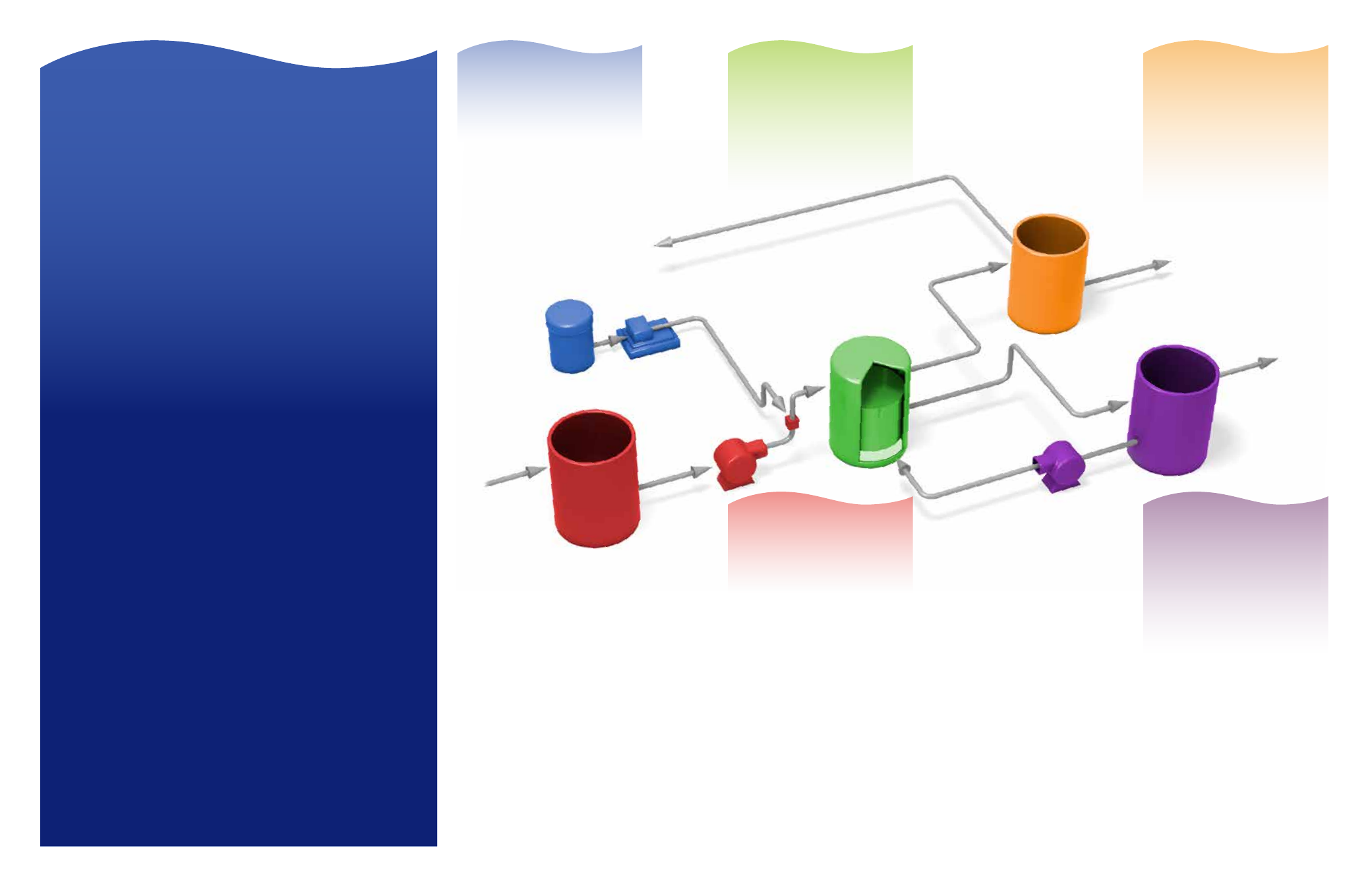

Single Nutrient Addition

GE’s single nutrient is automatically

dosed into the common biofilter

feed line to maintain the ORP in the

biofilter within the optimal range

for maximum selenium removal.

What can ABM

et

remove?

ABMet removes nitrate and nitrite to

non-detect levels through a biological

denitrification process within the

biofilter resulting in the formation and

off-gassing of nitrogen gas. ABMet

also removes selenium by biologically

reducing selenate and selenite to

particulate elemental selenium which is

then removed via the WASH sequence.

Single Nutrient

Storage

Nutrient

Pump Skid

Feed Tank

Influ

ent f

rom

Pretr

eatme

nt Sys

tem

To Pretreatment

System

Biofilter

As influent gravity flows downward

through the submerged biomatrix

(support media + biofilm), nitrate and

nitrite are reduced to nitrogen gas

first, then selenate and selenite are

reduced to particulate elemental

selenium. When a WASH sequence is

automatically performed, elemental

selenium is removed from the biofilter.

WASH Waste Removal

WASH waste solids are collected near

the top of the biofilter and flow by

gravity to a WASH waste storage tank,

pond, or solids handling system. Waste

is typically decanted and supernatant

recycled to the head of the system for

processing. Waste testing demonstrates

consistent non-hazardous classification

when using the USEPA TCLP test.

Feed System

The feed system controls the process

flowrate to each biofilter and blends

the nutrient into the biofilter feed

stream via a static mixer before the

stream splits into each biofilter.

Backwash System

The effluent tank stores effluent for

periodic backwashing of the biofilter

through the automatic DEGAS and

WASH sequences. DEGAS is a short

duration, periodic backwash for the

removal of gasses from the biomatrix.

WASH is a longer duration, periodic

backwash for the removal of gases and

solids, including elemental selenium.

In what types of applications

can ABM

et

be used?

The ABMet system has been demonstrated

in applications treating Flue-Gas

Desulfurization (FGD) wastewaters,

coal power plant ash landfill leachate,

coal mine waters, phosphate mine

waters, metal refinery wastewater,

and agricultural runoff waters.

What are the process

constraints?

Nitrate-N . . . . . . . . .< 250 mg/l

Chloride . . . . . . . . . .< 25,000 mg/l

TSS . . . . . . . . . . . . . . .< 250 mg/l

Temperature . . . . . .40 to 105ºF (5 to 40ºC)

pH . . . . . . . . . . . . . . . .6–9

What flow rates can be

treated with ABMet?

ABMet’s innovative modular design is

scalable and can be adapted to treat

any flow rate. Full scale systems have

been designed to treat flows from

25 to 1400 gpm (6 to 318 m

3

/h).

WASH

Waste

super

natant

Feed Pump

WASH Waste Tank

To Sol

ids

Handl

ing

Backwash

Pump

Efflu

ent T

o Dischar

ge

Effl

uen

t

WASH

Waste

Backwash

Supply

Biofilter

Effluent Tank