Hot water sanitization recommendations, Table 1: element specification, Table 3: operating parameters – GE P&W Spiral Wound Membranes - Dairy HWS User Manual

Page 2: Table 4: cip limits for ro elements, Table 5: cip limits for nf elements

Page 2

Fact Sheet

Table 1: Element Specification

Membrane

Thin-film membrane (TFM*)

Model

Spacer

mil (mm)

Active area

ft

2

(m

2

)

Part

number

Dairy HWS RO3840C30

30 (0.76)

85 (7.9)

1228223

Dairy HWS RO8038C30

30 (0.76)

390 (36.2)

1206651

Dairy HWS NF3840C30

30 (0.76)

85 (7.9)

1232322

Dairy HWS NF8038C50

50 (1.27)

360 (33.4)

3002372

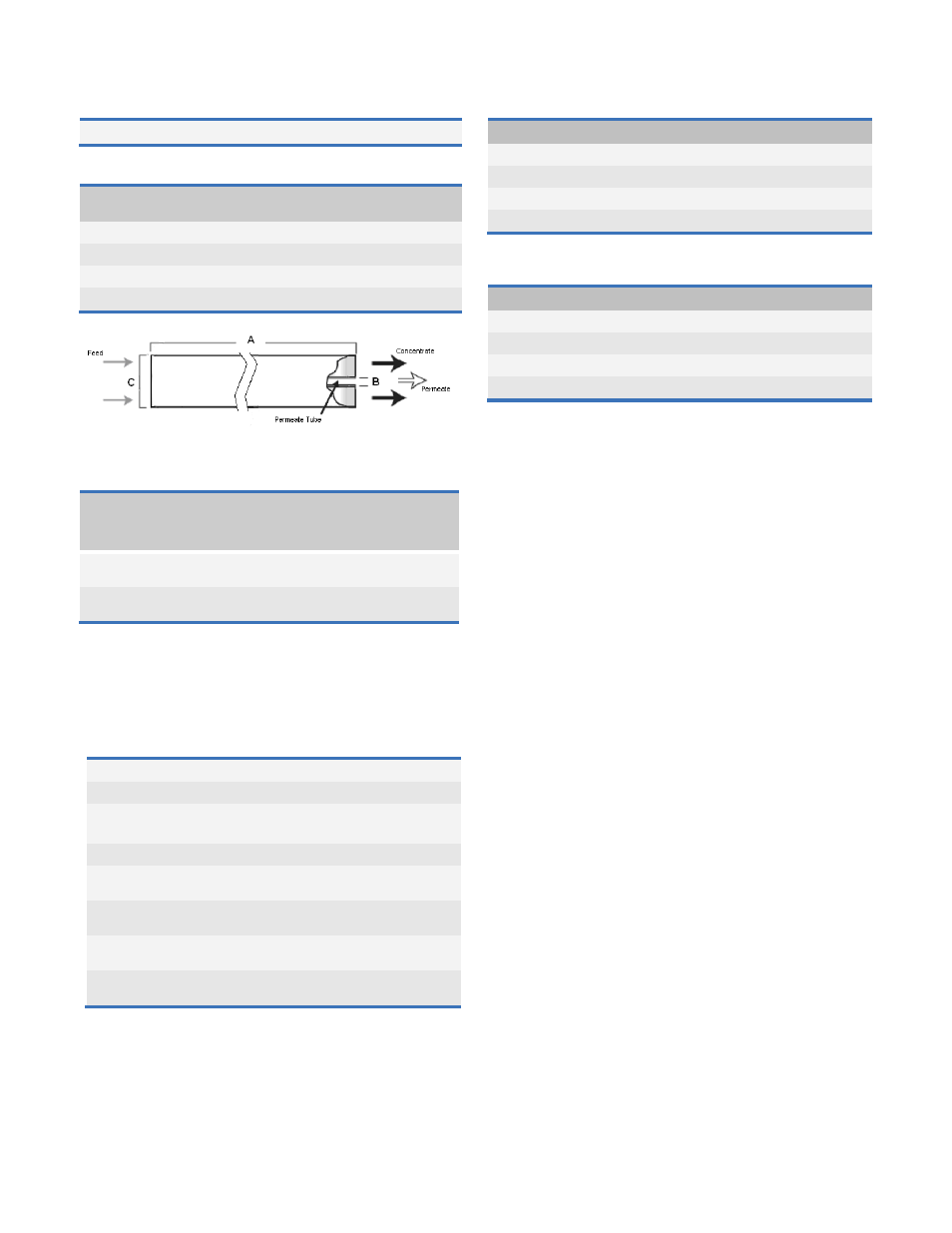

Figure 1: Element Dimensions Diagram - Female

Table 2: Dimensions and Weight

Model

1

Dimensions, inches (cm)

Boxed

A

B

2

C

Weight

lbs (kg)

3840C

38.75

(98.4)

0.833

(2.12)

3.8

(9.6)

7

(3.2)

8038C

38.00

(96.52)

1.125

(2.86)

7.91

(20.1)

29

(13.2)

1

These elements are dried and bagged before shipping.

2

Internal diameter.

Table 3: Operating parameters

Do not exceed 20 GFD (33 LMH) or 2,000 Wagner

units under any circumstance.

Typical Operating Pressure

200-500 psi (1,379-3,447 kPa)

Typical Operating Flux

5-20 GFD (8–34 LMH)

Clean Water Flux

1

RO : 14 GFD (24 LMH)@ 225 psi

NF : 14 GFD (24 LMH) @ 110 psi

Maximum Operating Pressure

600 psi (4,137 kPa): 41 – 122°F (26 – 50°C)

Maximum Temperature

Continuous operation: 122°F (50°C)

Hot Water Sanitization: 194°F (90°C)

pH Range

RO elements: 3.0 – 10.0

NF elements: 3.0 – 9.0

Chlorine Tolerance

500+ ppm hours,

dechlorination recommended

Maximum Pressure Drop

Over an element: 15 psi (103 kPa)

Per housing: 60 psi (414 kPa)

1

Clean water flux (CWF) is the rate of water permeability through the membrane

after cleaning (CIP) at reproducible temperature and pressure. It is important to

monitor CWF after each cleaning cycle to determine if the system is being

cleaned effectively. CWF can vary ±25%.

Table 4: CIP limits for RO elements

Temperature

‘

pH minimum

‘

pH maximum

50°C (122°F)

2.0

11.5

45°C (113°F)

1.5

11.5

35°C (95°F)

1.5

11.5

25°C (77°F)

1.0

12.0

Table 5: CIP limits for NF elements

Temperature

‘

pH minimum

‘

pH maximum

50°C (122°F)

3.0

10.0

45°C (113°F)

2.0

10.5

35°C (95°F)

1.5

11.5

25°C (77°F)

1.0

11.5

Hot Water Sanitization

Recommendations

For optimal performance, Dairy HWS elements

should always be cleaned using approved CIP

procedures and flushed with fouling free water

before the sanitization process. Feed pressure

during sanitization should not exceed 40psi

(275kPa) and the crossflow should not incur a

pressure drop greater than 2psi (14kPa) per

element. Heating rate to sanitizing temperature and

cool down should not be faster than 5°C (41°F) per

minute. Maximum sanitization temperature is 90°C

(194°F).

Loss of Permeate Flow after Repeated

90°C Sanitization Cycles

It is almost impossible to exactly predict the per-

centage of permeate flow rate lost from the high

temperature sanitations, which among other fac-

tors depends on:

1) Rate of temperature increase and decrease.

2) Presence of other species like organics, ionic

and metallic compounds that could locally de-

crease or increase the temperature at the sur-

face of the membrane.

3) Feed flow rate and specifically the heat transfer

rate to the membrane surface.

4) The thickness and geometry of the feed spacer

used.