Rainbow Electronics MAX9216 User Manual

Page 12

MAX9210/MAX9212/MAX9214/MAX9216/MAX9220/MAX9222

Programmable DC-Balance

21-Bit Deserializers

12

______________________________________________________________________________________

bias resistors, along with the 100

Ω ±1% tolerance ter-

mination resistor, provide +15mV of differential input.

However, the +15mV bias causes degradation of

RSKM proportional to the slew rate of the clock input.

For example, if the clock transitions 250mV in 500ps,

the slew rate of 0.5mV/ps reduces RSKM by 30ps.

Unused LVDS Data Inputs

In non-DC-balanced mode, leave unused LVDS data

inputs open. In non-DC balanced mode, the input fail-

safe circuit drives the corresponding outputs low and no

pullup or pulldown resistors are needed. In DC-balanced

mode, at each unused LVDS data input, pull the inverting

input up to V

CC

using a 10k

Ω resistor, and pull the nonin-

verting input down to ground using a 10k

Ω resistor. Do

not connect a termination resistor. The pullup and pull-

down resistors drive the corresponding outputs low and

prevent switching due to noise.

PWRDWN

Driving PWRDWN low puts the outputs in high imped-

ance, stops the PLL, and reduces supply current to

50µA or less. Driving PWRDWN high drives the outputs

low until the PLL locks. The outputs of two deserializers

can be bused to form a 2:1 mux with the outputs con-

trolled by PWRDWN. Wait 100ns between disabling one

deserializer (driving PWRDWN low) and enabling the

second one (driving PWRDWN high) to avoid con-

tention of the bused outputs.

Input Clock and PLL Lock Time

There is no required timing sequence for the applica-

tion or reapplication of the parallel rate clock (RxCLK

IN) relative to PWRDWN, or to a power-supply ramp for

proper PLL lock. The PLL lock time is set by an internal

counter. The maximum time to lock is 32,800 clock

periods. Power and clock should be stable to meet the

lock time specification. When the PLL is locking, the

outputs are low.

Power-Supply Bypassing

There are separate on-chip power domains for digital

circuits, outputs, PLL, and LVDS inputs. Bypass each

V

CC

, V

CCO

, PLL V

CC

, and LVDS V

CC

pin with high-fre-

quency, surface-mount ceramic 0.1µF and 0.001µF

capacitors in parallel as close to the device as possi-

ble, with the smallest value capacitor closest to the

supply pin.

Cables and Connectors

Interconnect for LVDS typically has a differential imped-

ance of 100

Ω. Use cables and connectors that have

matched differential impedance to minimize impedance

discontinuities.

Twisted-pair and shielded twisted-pair cables offer

superior signal quality compared to ribbon cable and

tend to generate less EMI due to magnetic field cancel-

ing effects. Balanced cables pick up noise as common

mode, which is rejected by the LVDS receiver.

Board Layout

Keep the LVTTL/LVCMOS outputs and LVDS input sig-

nals separated to prevent crosstalk. A four-layer PC

board with separate layers for power, ground, LVDS

inputs, and digital signals is recommended.

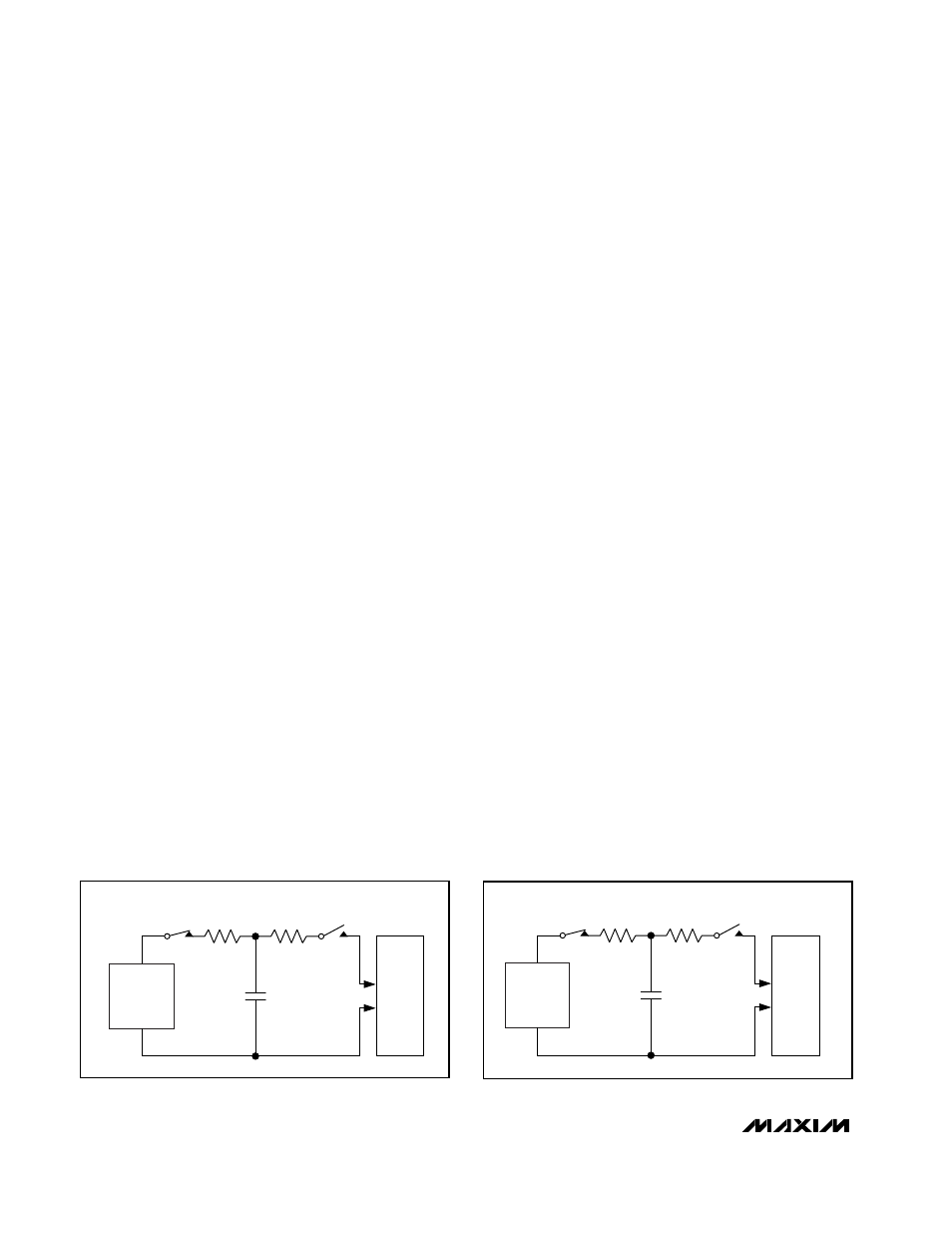

IEC 61000-4-2 Level 4 ESD Protection

The IEC 61000-4-2 standard specifies ESD tolerance

for electronic systems. The IEC 61000-4-2 model

(Figure 14) specifies a 150pF capacitor that is dis-

charged into the device through a 330

Ω resistor. The

MAX9210/MAX9212/MAX9214/MAX9216/MAX9220/

MAX9222 LVDS inputs are rated for IEC 61000-4-2

level 4 (

±8kV contact discharge and ±15kV air dis-

charge). IEC 61000-4-2 discharges higher peak current

and more energy than the HBM due to the lower series

resistance and larger capacitor. The HBM (Figure 15)

specifies a 100pF capacitor that is discharged into the

device through a 1.5k

Ω resistor. All pins are rated for

±5kV HBM.

STORAGE

CAPACITOR

HIGH-

VOLTAGE

DC

SOURCE

DEVICE

UNDER

TEST

CHARGE-CURRENT-

LIMIT RESISTOR

DISCHARGE

RESISTANCE

R1

50

Ω TO 100Ω

R2

330k

Ω

C

S

150pF

Figure 14. IEC 61000-4-2 Contact Discharge ESD Test Circuit

STORAGE

CAPACITOR

HIGH-

VOLTAGE

DC

SOURCE

DEVICE

UNDER

TEST

CHARGE-CURRENT-

LIMIT RESISTOR

DISCHARGE

RESISTANCE

R1

1M

Ω

R2

1.5k

Ω

C

S

100pF

Figure 15. Human Body ESD Test Circuit