Enclosed drive lubrication, Fig. 30, Reduction sweep wheel – Grain Systems Unload Augers PNEG-1050 User Manual

Page 35: Belt tension, Trouble shooting

35

12" & 14" Commercial Bin Sweep Augers PNEG-1050

Maintenance

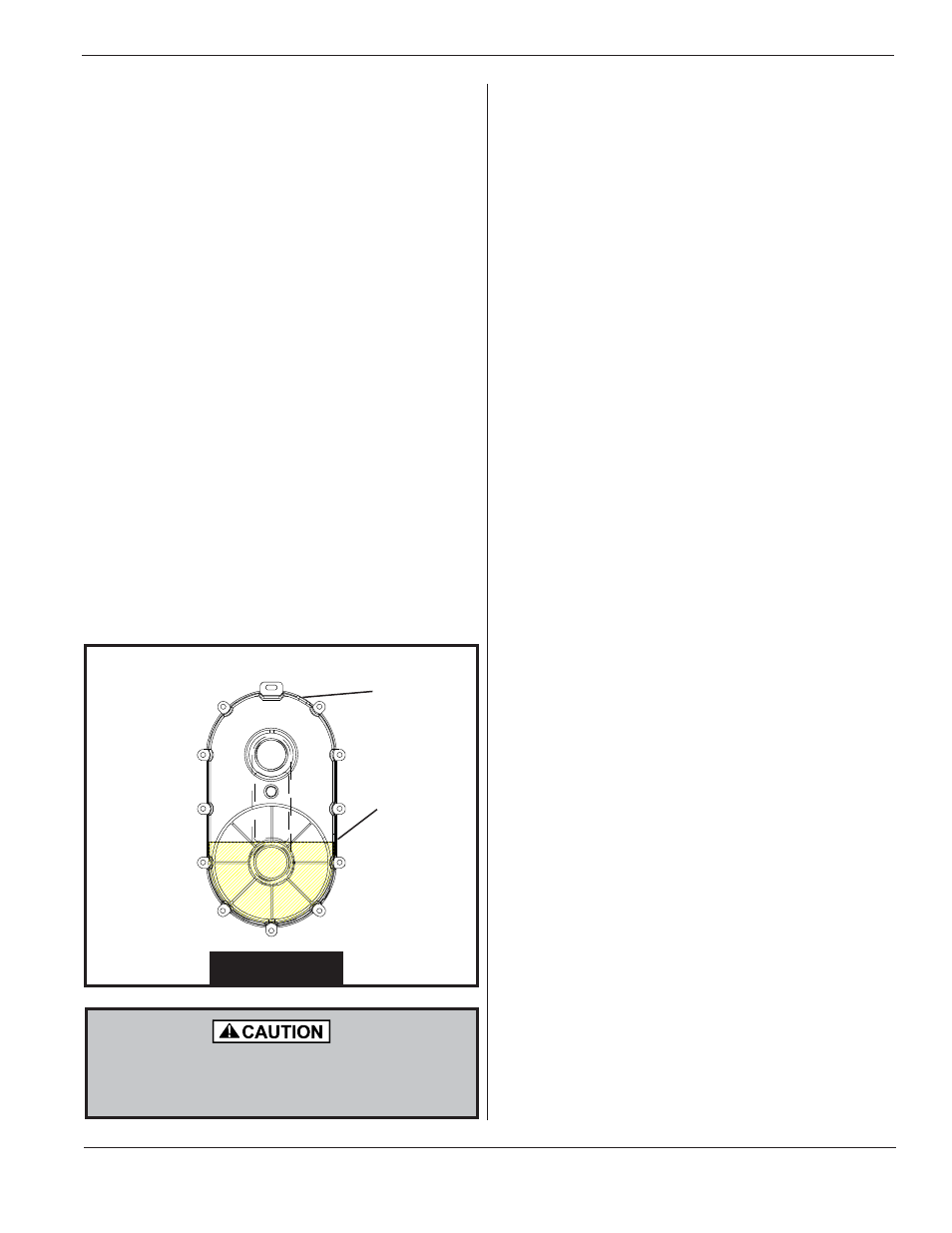

14. ENCLOSED DRIVE

LUBRICATION

A. The enclosed drive is located at the discharge

end of the auger housing and is shipped without

oil. Oil is to be added to the unit during field

assembly of the auger. Oil will dissipate under

normal operating conditions, therefore the oil

level should be checked regularly. Add 90 EP

(non-foaming) oil until the oil level reaches the

check point.

B.

For lubrication in normal operating temperature

between 40º F to 120º F, we recommend the

use of non-foaming, multi purpose gear oil. Use

SAE 90 weight for normal operating tempera-

tures. For temperatures below 40º F, use SAE

80 weight oil. Use a grade of oil commercially

available for automotive differentials. Extra

pressure additives may be of value in severe

applications.

FIG. 30

DO NOT add more oil than recommended.

Additional oil may damage the seals or be forced

out through the vented plug.

Enclosed Drive

Check Plug

Fill Plug

15. REDUCTION SWEEP WHEEL

A. Add two ounces of multi purpose gun grease to the

sweep wheel drive enclosure during assembly and

each time the bin has been emptied. Use the grease

zerk on the drive housing.

13. BELT TENSION

A. Check the belt tension on electric drive. To tighten

belts, use the adjusting rod on the motor mount

assembly. DO NOT over tighten belts.

A. LOW CAPACITY

Sweep capacity may vary as the angle of sloping grain

varies. Check the horsepower requirements on pages 34,

to determine correct operating speed and the motor pulley

size recommended for that speed. If a greater or lower

capacity is desired it may be possible to change the

motor pulley which will change the sweep flight speed. Do

not attempt operation at speeds greater than 50 to 100

RPM above standard recommended speed. Do not operate

a sweep that is overfeeding the unloading auger unit. The

slide gate in the center well should be left full open during

sweep operation.

B. SWEEP FLIGHT & BACK SHIELD NOT MOVING

DO NOT STORE SWEEPS IN THE BIN!

Sweeps are NOT designed to remain in a bin during filling,

storage, or bottom (gravity) unloading. A sweep left in a bin

during these operations may be serverly damaged. The

GSI Group, Inc. will not be responsible for such damages.

The following action may reduce damages to a sweep

remaining in a bin: Lifting the sweep off the center pivot,

positioning it parallel to the intermediate wells (along side

of - not on top of) and fully supporting the sweep to the bin

floor. However, even with this procedure, The GSI group,

Inc. will not be responsible for any damges to the sweep.

Check clearance between back shield and the bin floor for

excessive drag. It may be possible to adjust the back

shield up by working the slotted connections between

back shields at bearing brackets.

The grain may have gone out of condition due to moisture

or insect activity and has become hard or caked. Stop the

sweep auger and lockout power before entering the bin to

correct this or any other difficulty. Make sure the grain

hasn’t flowed abnormally or bridged over. See page 30 for

illustrations.

16. TROUBLE SHOOTING