Grain Systems Unload Augers PNEG-1050 User Manual

Page 14

14

12" & 14" Commercial Bin Sweep Augers PNEG-1050

Assembly

1. CHAIN REDUCER DRIVE (For 36' thru 78' Diameter Bins)

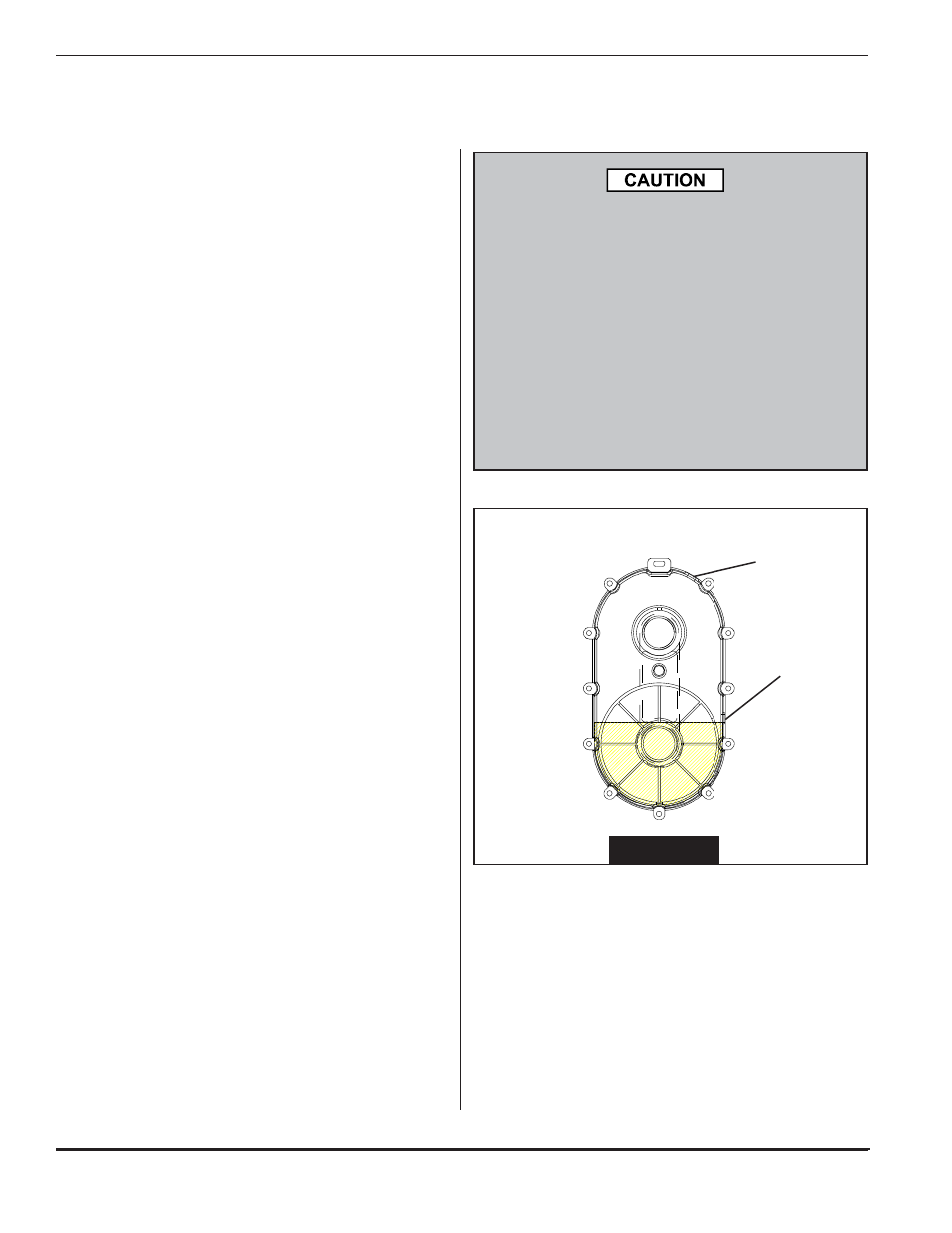

Oil must be added before assembly. The chain

reducer is shipped without oil.

Do NOT add more oil than recommended. Addi-

tional oil may damage the seals or be forced out

through the vented fill plug.

For lubrication in normal operating temperature

between 40° F to 120° F, we recommend the use

of non foaming, multi purpose gear oil, SAE 90

weight. For temperatures below 40° F, use a SAE

80 weight oil. Use grade commercially available

for automotive differentials. Extra pressure

additives may be of value in severe applications.

Enclosed Drive

Check Plug

Fill Plug

A. Motor Mount Assembly Instructions’

(See Fig. 2 on page 15.)

1.

First, fill the chain reducer drive with oil by removing

the vented fill plug and pouring 48 oz. of oil into drive.

Oil level can be checked by removing the check plug.

Oil should not be over the check plug. (See Fig. 1)

2.

Install Pivot Bracket (1) to bottom of motor mount

frame (2) using a 3/4" x 11" long (grade 5) hex head

capscrew and nylon locknut.

3. Attach the electric cord support stand (3) and one side

of the motor mount support plate (4) to the motor

mount frame (2) using two 1/2" x 1-1/2" long (grade 5)

hex head capscrews with lock washers and hex nuts.

Attach the other side of the motor mount support plate

(4) to the motor mount frame (2) using two 1/2" x

1-1/4" long capscrews with lockwashers and nuts.

4. Mount the chain reducer drive (6) to the mounting ring

on the motor mount frame (2) with four 3/8" x 1" long

(grade 5) hex head capscrews and nylon locknuts.

5. Screw the 3/4" threaded adjusting rod (7) down through

the nut welded to the top of the motor mount support

plate (4). Leave the adjusting rod (7) an inch or two

above the top surface of the motor mount support

plate (4). The adjusting rod will be adjusted later after

the drive belts are installed.

6. Thread a 3/4" hex nut onto the bottom end of the

adjusting rod (7) underneath the motor mount support

plate (4). This nut is for locking the adjusting rod in

place after adjusting it to the required position to

tighten the drive belts. DO NOT tighten this nut

against the motor mount support plate until the belts

have been installed and tightened.

7. Align the pivot holes (10) of the motor mount plate (4)

with those in the motor mount support plate (4) and

slide the pivot rod (9) through the holes. Insert a 3/16"

cotter pin into the holes in each end of the pivot rod (9)

to keep it in place.

FIG. 1