Sweep tractor assembly (see fig. 18), Assembly – Grain Systems Unload Augers PNEG-1050 User Manual

Page 28

28

12" & 14" Commercial Bin Sweep Augers PNEG-1050

Assembly

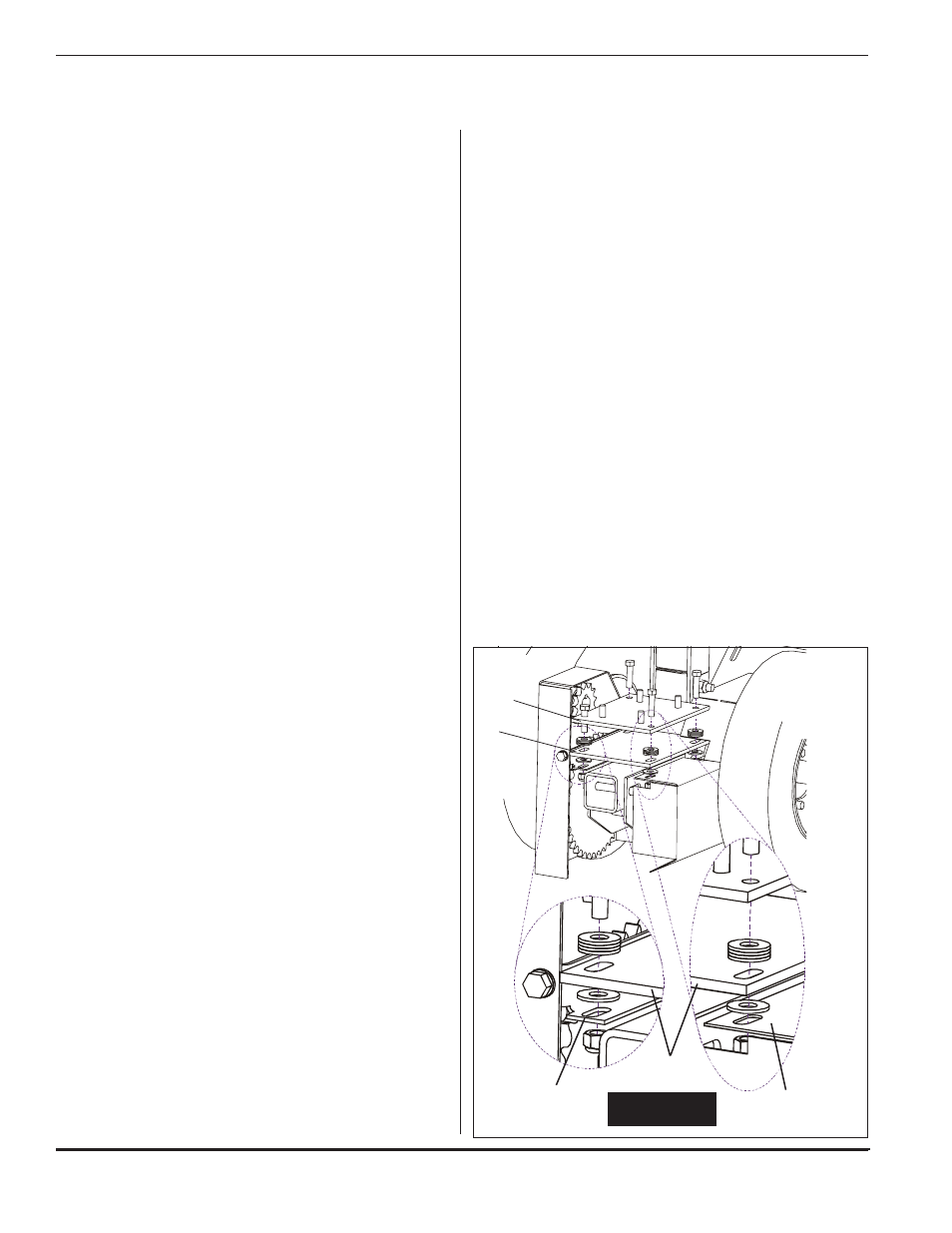

8. SWEEP TRACTOR ASSEMBLY (SEE FIG. 18)

1.

Remove wheel hubs from axle. (Assembled for

shipping only.)

2.

Bolt the adapter plate (2) to the gear motor (3) using

four 3/8" x 1" hex head capscrews with four 3/8"

lockwashers.

3.

Install right side chain around the right side sprockets.

4.

Slide right side chain guard (12) onto the axle.

5.

Bolt the adpater plate (2) to the gear motor mount by

placing a 3/8" x 1-1/2" through the left side slots in the

adapter plate (2), four flat washers, gear motor mount

(4), one flat washer, the right side chain guard (12),

and finally, a hex nut. Repeat this with the left side

slots in the adapter plate (12), but replace the right

side chain guard with the left side chain guard mount

bracket (14). (See Fig. 17)

6.

Attach the other right side chain guard flange &

support tube weldment (7) to the sweep tractor

assembly using (2) 1/2" x 4" hex head capscrews and

nuts.

7.

Assemble 13 tooth sprocket (5) to gear motor shaft (6)

using a 1/4" key x 1" long. Align 13 tooth sprocket (5)

with 40 tooth sprocket (6) before tightening the

sprocket setscrews.

8.

Install chain around the sprockets. Use slots in gear

motor mount to tighten the chain. Once chain is tight,

completely tighten bolts that hold gear motor to mount

from step 5.

9.

Bolt the left side chain guard (12) to the mount

bracket (14) using (2) 3/8" x 1" HHCS & lock washers.

10. Replace wheel hubs onto the axle.

11. Assemble segmented rubber wheel (1) to hubs with

1/2" nylon locknuts (four for each wheel.)

12. Slide the weight bracket weldment (8) onto the

support tube weldment (7) and secure with a

3/16" x 1-1/2" cotter pin.

13. Place the 50 lb. weights (9) on the weight bracket

weldment (8).

14. Loosely attach the weight clamps (10) to the weight

bracket (11) using two 1/4" x 3/4" carriage bolts,

1/4" lockwasher, & 1/4" flat washer. Do not tighten yet

to allow for adjustment later on.

15. Attach the weight bracket (11) to the weight bracket

weldment (8) with a 3/4" hex nut. Tighten the nut so

the weight bracket is securely against the top of the

50 lb. weights (9).

16. Slide the weight clamps (10) out against the sides of

the 50 lb. weights (9) and tighten to secure the

weights in place.(See Fig. 17.)

17. Electric wiring for motor and controls shall be installed

by a qualified electrician and must meet the standards

set by the National Electrical Code and all local and a

state codes.

18. Run wiring for motor forward to the sweep shield along

sweep mount tube. Attach the wiring to the mount

sufficiently to keep wiring from contacting sweep

tractor wheels.

19. At the center of the bin the wiring for the tractor may

either be connected with the sweep flight motor wiring

or a separate wire may be run to the outside of the

bin. If the tractor wiring is connected to the wiring for

the sweep flight motor, then the tractor will turn on and

off with the sweep. If a separate wire is run to the

outside of the bin, then the tractor can be operated

independently.

(13) Left Side

Chain Guard

(12) Right Side

Chain Guard

FIG. 17

(4) Gear

Motor Mount

NOTE:

Motor not

shown for

clarity.

(2)

Adapter

Plate

(4)

Gear

Motor

Mount