Flight and shield assembly (cont.), Assembly – Grain Systems Unload Augers PNEG-1050 User Manual

Page 23

23

12" & 14" Commercial Bin Sweep Augers PNEG-1050

Assembly

3. FLIGHT AND SHIELD ASSEMBLY (cont.)

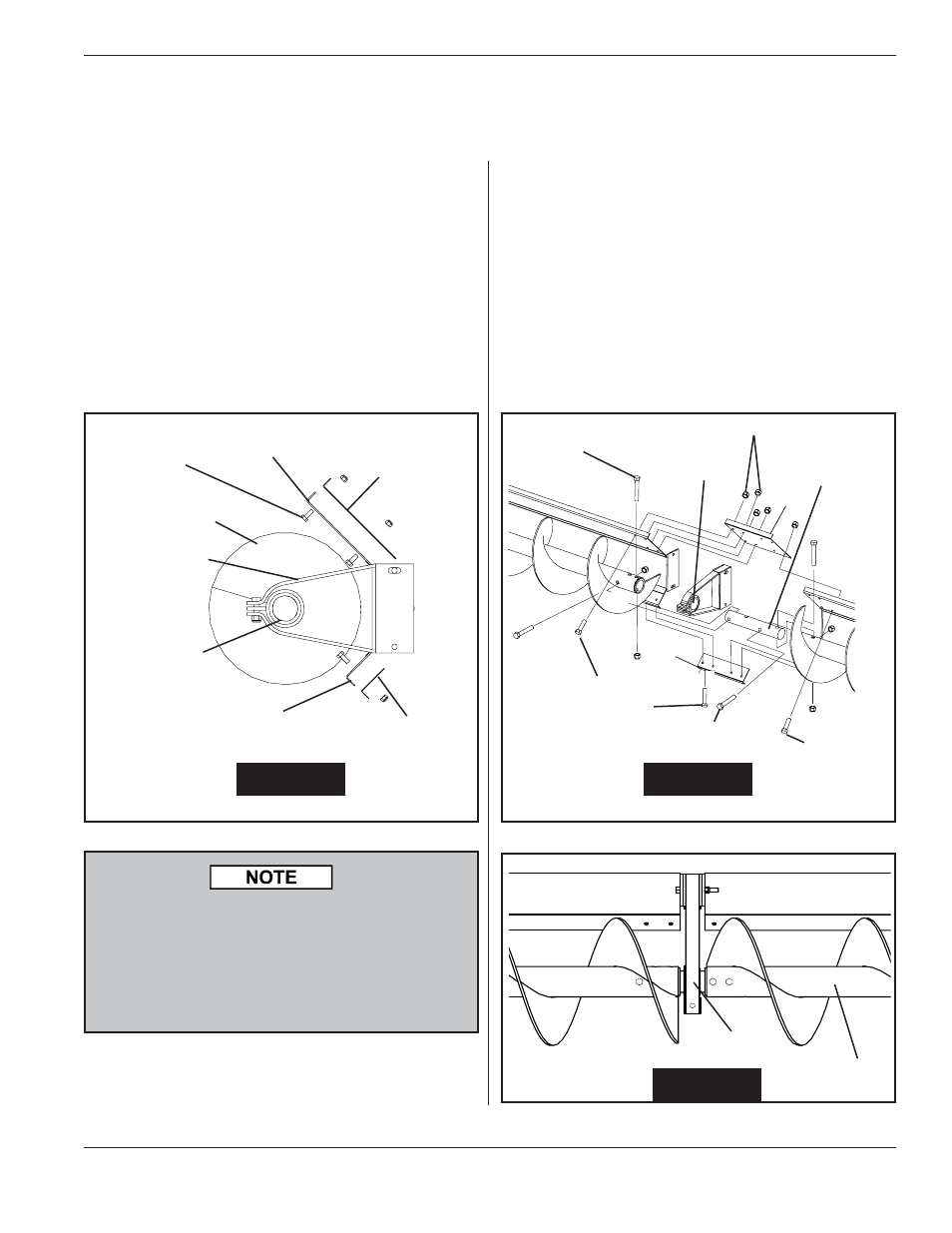

E. Attach sweep back shield splice plates (8 & 9) to

back side of the sweep back shield. Use eight 5/16" x

3/4" hex head capscrew and nylon locknuts for each

upper splice plate. Use four 5/16" x 3/4" long hex

head capscrews and nylon locknuts for each lower

splice plate. (See Fig. 9 & 10.)

F.

Slide the flight connecting stub (10) through the

bronze bearing (11) and into the next flight section.

Connect the flight sections together using two 5/8" x

4" hex head capscrews and nylon locknuts.

(See Fig. 10 & 11.)

Bearing

Stand

Sweep Flight

Upper Portion

of Sweep Back

Shield

Sweep Flight

(11) Bronze

Bearing

(8) Upper Back

Shield Splice

Plate

(9) Lower Back

Shield Splice Plate

Lower Portion of Sweep

Back Shield

(7) Bearing

Stand

5/16" x 3/4"

HHCS &

Locknuts

FIG. 9

Splice Plate Side View

FIG. 11

5/8" x 4" HHCS

with Locknut

5/16" Locknuts

5/16" x 3/4"

HHCS

5/16" x 3/4"

HHCS with

Locknut

5/8" x 4" HHCS

with Locknut

(11) Bronze

Bearing

(10) Connecting

Stub

FIG. 10

Splice Plate Angled View

G. Repeat steps C-F for the other add-on sweep back

shield and flight sections. (NOTE: Units that use four

or more sections of flight include a sweep carrier

assembly that is used in conjunction with a truss

stand. (See Fig. 6 on page 20 for locations.) A cable

truss is also provided for the sweep back shields on

these units. The truss stand will fasten to the sweep

carrier assemblies. Fasten the truss stand to the

sweep carrier with 3/8" x 1" long hex head capscrews.

(See Fig. 12 on page 24.) Use 3/8" x 3-1/2" hex head

capscrews to connect the sweep carrier, sweep back

shield and bearing stand together.

The sweep flights are indexed to achieve “timed”

connections ( A “timed” connection is where the

flight pitch does not change across the connection.)

When bolting timed flight sections together at the

bearing stand, position the flight ends so they are

open 90° to 180° to one another.

(8)

(9)