Guidelines for connecting natural gas to a dryer, Specifications and recommendations for natural gas, Chapter 8: fuel supply – Grain Systems PNEG-1891 User Manual

Page 53

Guidelines for Connecting Natural Gas to a Dryer

When initially installing the dryer, you must connect a fuel source before you can operate the dryer. Natural

gas (NG) is one possible fuel choice.

• Operate the dryer on natural gas with a heat value of approximately 1000 BTU (880 kWper cubic

foot).

NOTE: The dryer is equipped with a natural gas supply pipe system connected to the heater solenoid

valves.

• You must provide a regulated pressure of 15 PSI at the connection to the dryer with sufficient gas

available to maintain this operating pressure.

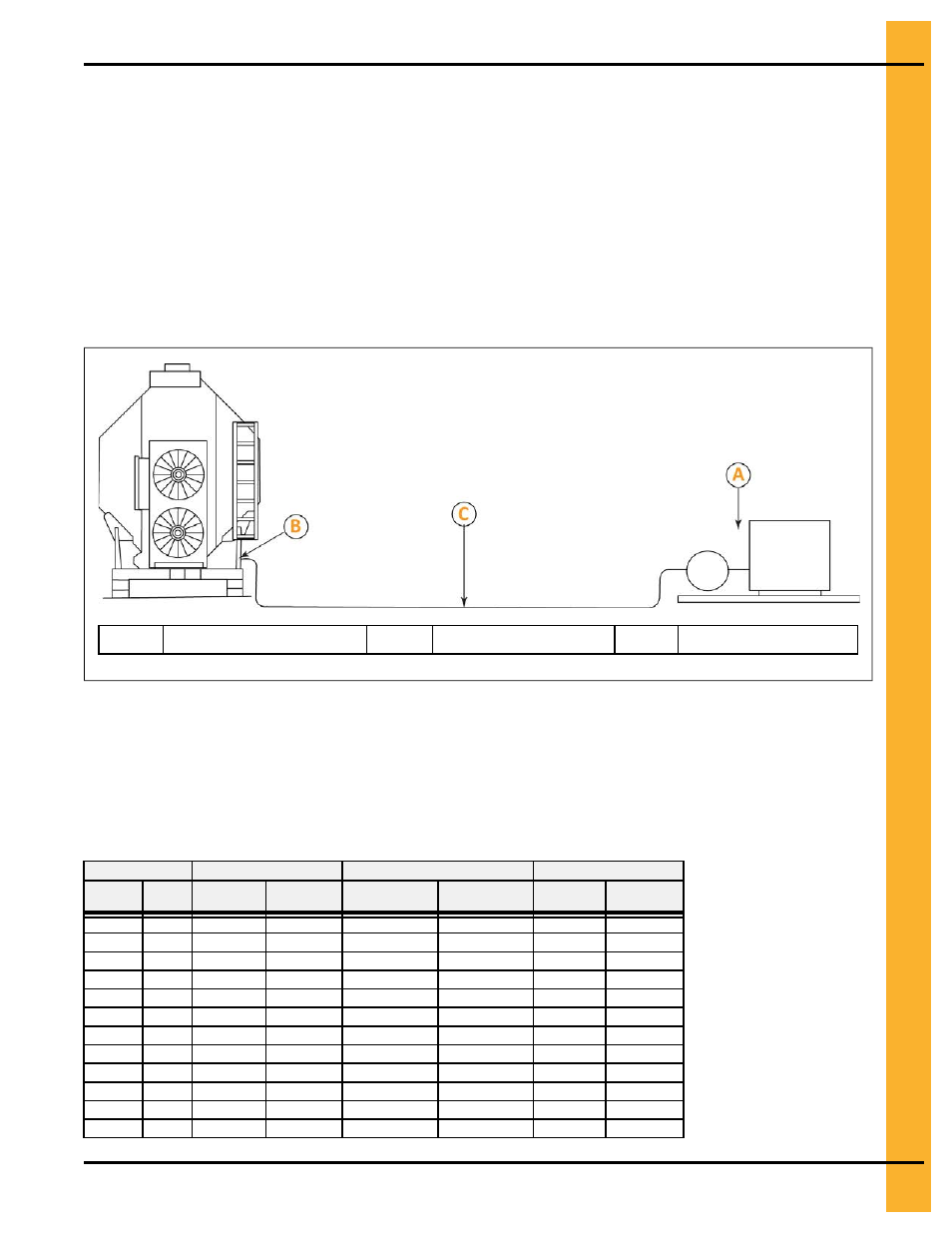

Figure 8-2 Grain dryer connected to a natural gas supply tank

A

Gas meter and regulator

B

Natural gas manifold

C

Fuel supply pipe

Specifications and Recommendations for Natural Gas

The fuel line size and heater orifice size are determined by the dryer model heat capacity and fuel flow

rate. Use the specifications chart that follows to select the appropriate equipment for your dryer.

Table 8-2 Specifications for natural gas (NG)

Dryer Model #

Maximum Heat Capacity

Maximum Fuel Flow

Fuel Line Size*

GSI

FFI

BTU Per

Hour

Kilowatt

Hours

Gallons Per

Hour (gph)

Liters Per

Hour (l/hour)

Inches

Millimeters

1108

190

3,000,000

879

33

124.9

0.50

25.4

1112

270

4,500,000

1319

49

185.5

0.50

25.4

1114

320

5,750,000

1685

63

238.5

0.50

25.4

1116

370

5,750,000

1685

63

238.5

0.50

25.4

1118

400

6,750,000

1978

74

280.1

0.50

25.4

1120

460

7,500,000

2198

82

310.4

0.50

25.4

1122

511

8,750,000

2564

96

363.4

0.75

76.2

1126

601

10,250,000

3004

112

424

0.75

76.2

1214

2120

6,200,000

1817

68

257.4

0.75

76.2

1216

2122

7,200,000

2110

79

299

0.75

76.2

1218

2125

7,200,000

2110

79

299

0.75

76.2

1220

2130

8,500,000

2491

93

352

0.75

76.2

Pneg-1891 Portable Dryers

53