Chapter 2: installation guidelines – Grain Systems PNEG-1891 User Manual

Page 13

Chapter 2: Installation Guidelines

To prevent the dryer from overturning or moving laterally, the dryer must be secured to the foundation

using anchor bolts or cables. Anchor bolts can be cast into the concrete slab and secured to the dryer

legs. The dryer can also be secured using cables and turnbuckles that are fastened to the anchors that are

installed at the edge of the concrete slab.

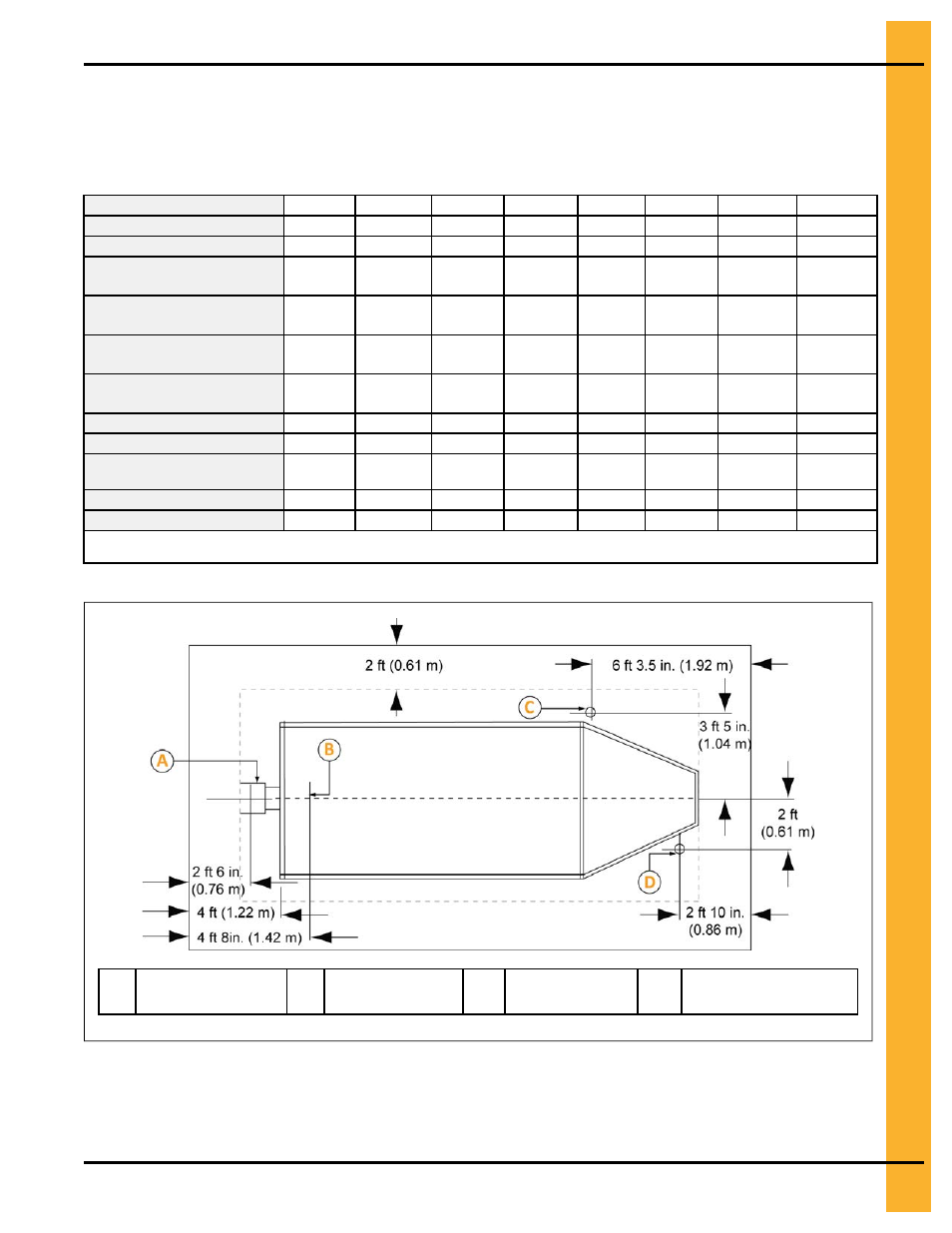

Table 2-1 General reference for concrete materials needed for each size dryer foundation.

Dryer basket length

8

12

14

16

18

20

22

26

Concrete pad size (ft x ft)

12 x 18

12 x 22

12 x 24

12 x 26

12 x 28

12 x 30

12 x 32

12 x 36

Concrete pad size (m x m)

3.7 x 5.5

3.7 x 6.7

3.7 x 7.3

3.7 x 7.9 3.7 x 8.5 3.7 x 9.1

3.7 x 9.8

3.7 x 11

Concrete yards (meters)

5.9 (5.4)

7.1 (6.5)

7.7 (7.0)

8.3 (7.6) 8.9 (8.1) 9.2 (8.4) 10.1 (9.2)

11.3

(10.3)

Quantity of reinforcing rods

20 in. (50.8 cm) each

6

7

7

8

8

8

9

10

Wire mesh sq—ft (sq m )

20.0

(216)

24.5

(264)

26.7

(288)

29.0

(312)

31.2

(336)

33.4

(360)

35.7

(384)

40.1

(432)

Steel legs (minimum

quantity)

8

10

12

12

14

14

16

18

Anchors

4

6

6

6

8

8

8

10

Blocks

14

18

18

18

22

22

26

30

Feet (Meters) of 2 x 6

boards

14 (4.3)

18 (5.5)

18 (5.5)

18 (5.5)

22 (6.7)

22 (6.7)

26 (7.9)

30 (9.1)

Quantity of turnbuckles

4

6

6

6

8

8

8

10

Estimated man-hours

10

14

18

18

20

22

24

28

Quantities are approximate and requirements might vary due to site elevations.

Setup times do not include site preparations and the pouring of the concrete pad.

Figure 2-3 Recommended locations for external equipment

A

Grain discharge

area

B

Fill-hopper

C

Gas pipe

location

D

Electrical service

location

Pneg-1891 Portable Dryers

13