Wheel bearing adjustment – Spicer Drive Axles Service Manual G & M User Manual

Page 25

23

WHEEL BEARING ADJUSTMENT

,,,

,,

,

,,

,

,

,

LUBRICANT LEVEL

LUBRICANT LEVEL

LUBRICANT LEVEL

LUBRICANT LEVEL

LUBRICANT LEVEL

NOTE: Wheel bearings should be adjusted following

vehicle manufacturers recommended maintenance

schedule.

1. Block wheels not being adjusted to insure that

vehicle will not roll. Release emergency brake.

2. Raise wheel to be adjusted off of the ground. Make

certain wheel rotates freely.

3. Remove axle shaft.

4. Remove outer adjusting nut and lock if tabs are

broken.

5. Torque inner wheel nut to 50 Lb-Ft (68 N-m) while

rotating wheel one direction, then the other direc-

tion. Back off inner nut 1/4 turn.

NOTE: When replacing wheel bearings, new bearings

must be re-seated to insure maximum service reliability.

After the hub and bearings are assembled in place on

the spindile, install the inner adjusting nut. Tighten the

inner adjusting nut to 120 - 140 Lb-Ft (163-190 N-m),

while rotating the hub to seat the bearings. Back off the

adjusting nut 1/2 turn and follow the proedure outlined

in step #5.

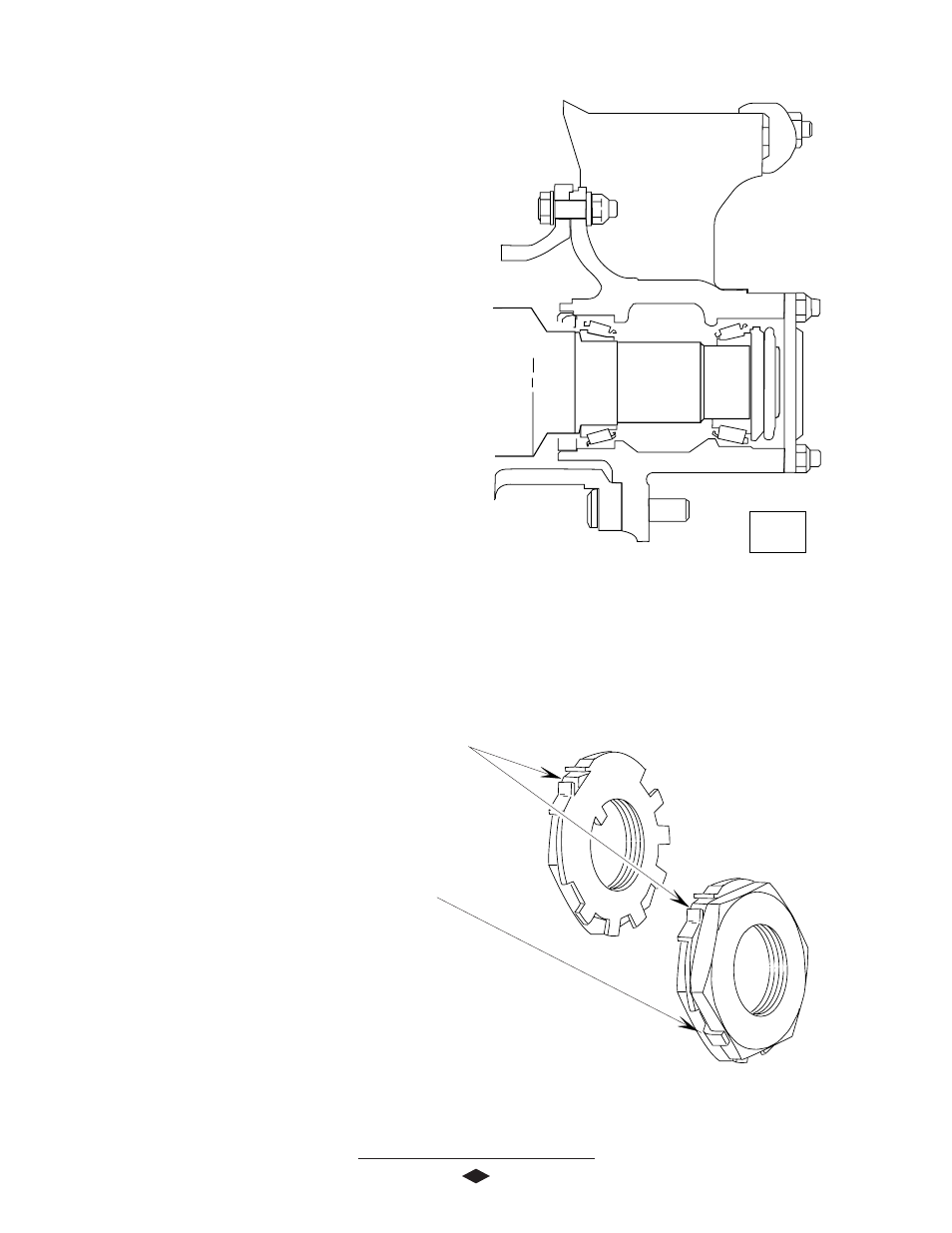

6. Install lock against inner wheel nut, with locking

portion positioned on either the flat side of inner

nut or peak of inner nut, as shown.

7. Install outer wheel nut and torque to 250-275 Lb-Ft

(340-373 N-m). Rotate wheel in both directions.

Wheel must rotate freely, with out binding.

8. Bend one tang of lock over flat portion of outer

wheel to secure.

9. Remove old axle flange gasket and clean mating sur-

faces of hub and axle flange.

10. Install new axle flange gasket.

11. Install axle shaft. Torque axle nuts to vehicle

manufacturers specifications.

Wheel Bearing Adjustment Complete