Pinion assembly – Spicer Drive Axles Service Manual G & M User Manual

Page 16

8. Rotate carrier to a vertical position. Place pinion

bearing spacer (selective) on pinion. Install outer

bearing cone onto pinion.

NOTE: The reason for not assembling a new pinion oil

seal at this time is due to the possibility of having to

adjust pinion preload or pinion position. It would be

necessary to again remove the seal and, as mentioned,

whenever seals are removed, they are to be discarded

because of possible damage.

9. Inspect end yoke seal surface for grooves caused by

seal lip. If grooves can be detected with a fingernail,

yoke should be replaced or have repair sleeve

installed.

10. Assemble end yoke, washer and old flanged hex nut

onto pinion. Torque nut to 700-900 Lb-Ft (949-

1,220 N-m). The old nut can be used during this

adjustment phase of the assembly, saving the new

one for final assembly.

11. Remove pinion retainer strap. Using an in-lb torque

wrench rotate pinion noting rolling torque. Rolling

torque of pinion should read between 20-50 in-lb

(2.3-5.7 N-m).

To increase preload, decrease thickness of preload

spacer: to decrease preload, increase thickness of

preload spacer. Every .001" (.025 mm) change in

thickness of preload spacer changes torque to

rotate by approximately 30 in-lb.

NOTE: A pinion bearing spacer (selective) is used to

develop pinion bearing preload. See list in next column

for available thicknesses. Measure the spacer with a

micrometer before assembly to insure correct thickness.

12. Remove flanged hex nut, washer and end yoke.

Apply a light coat of lubricant to the lip of the seal

and assemble into housing.

13. Assemble end yoke, washer, and new flanged hex

nut. Torque to 700-900 Lb-Ft (949-1,220 N-m).

Recheck torque to rotate.

PINION ASSEMBLY

14

Pinion bearing spacers (selective) are available in the

following thicknesses.

Inches

MM

Inches

MM

.700

17.780

.714

18.136

.701

17.805

.715

18.161

.702

17.831

.716

18.186

.703

17.856

.717

18.212

.704

17.882

.718

18.237

.705

18.907

.719

18.263

.706

18.932

.720

18.288

.707

18.958

.721

18.313

.708

18.983

.722

18.339

.709

18.009

.723

18.364

.710

18.034

.724

18.390

.711

18.059

.725

18.415

.712

18.085

.726

18.440

.713

18.110

.727

18.466

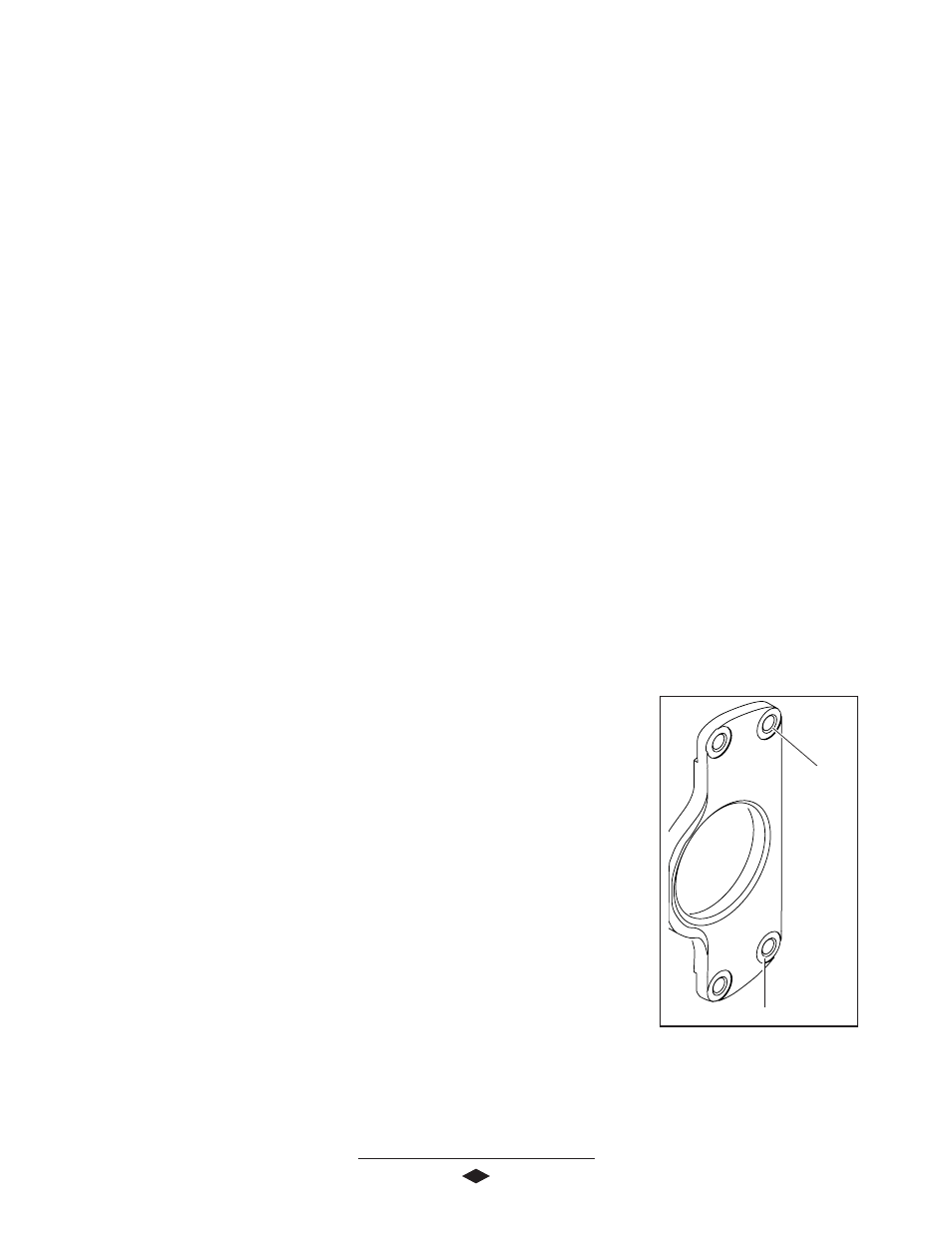

NOTE: Inspect pinion pilot bearing cap for proper

spotface and chamfer at the four bolt holes as shown in

Figure 10. If spotface and chamfer are not present,

machine as required .030 chamfer X 45º for holes and

1.25" spotface X .030

deep at four places.

14. Rotate carrier to

vertical position

with yoke down.

Install pinion pilot

bearing cap using

soft hammer if

necessary.

15. Install four retainer

bolts. Torque to:

G Model 70-80 Lb-

Ft (95-108 N-m)

M Model 110-125

Lb-Ft (149-169 N-m)

Chamfer

.030 x 45º

FFFFFigur

igur

igur

igur

igure 1

e 1

e 1

e 1

e 10

0

0

0

0

.030 Deep x 1.25 Spotface

Pinion Assembly Complete