Pinion assembly – Spicer Drive Axles Service Manual G & M User Manual

Page 15

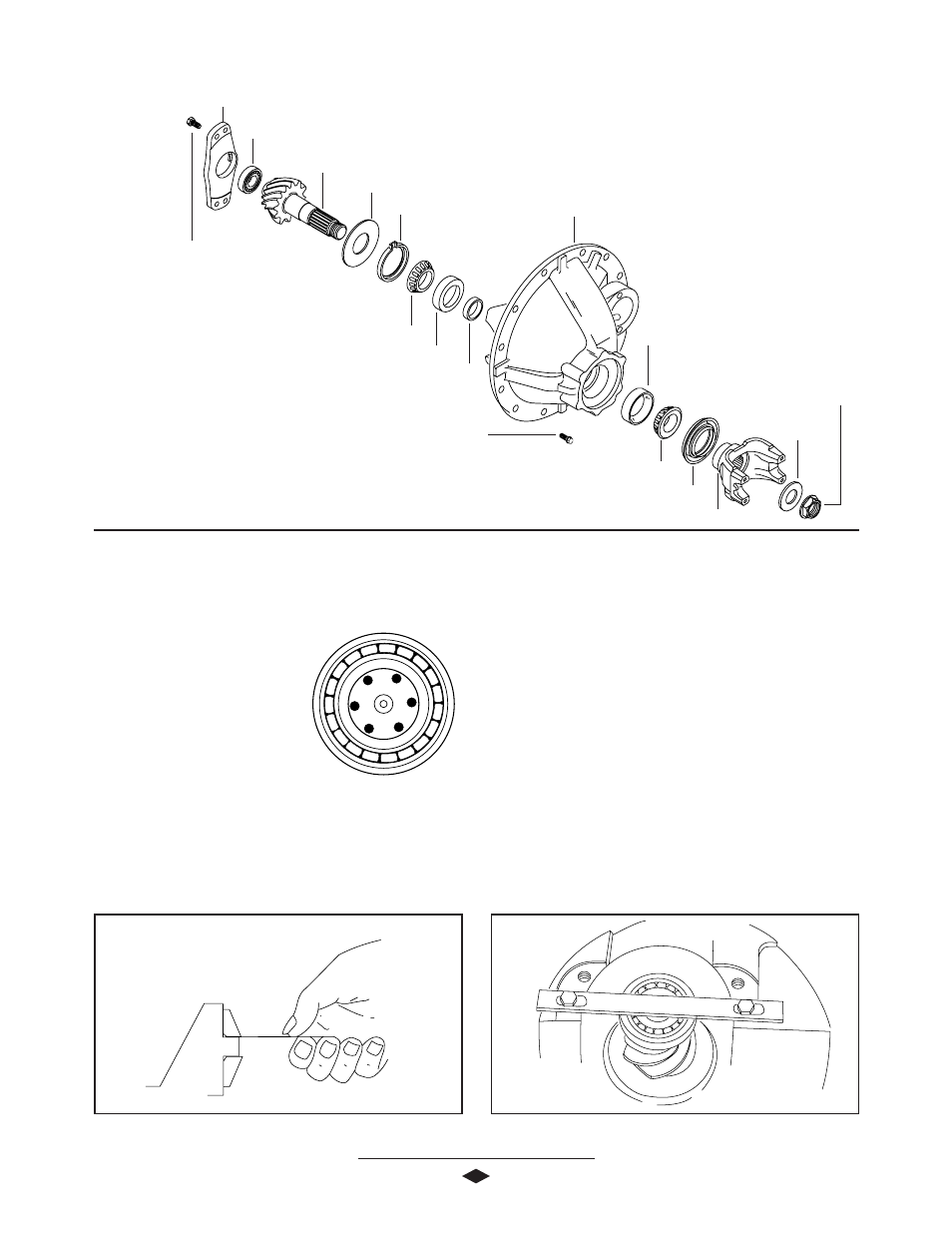

PINION ASSEMBLY

Pinion Bearing Spacer (Selective)

Pinion

Pinion Pilot Bearing Cap

Pinion Pilot Bearing

Retainer Plate Bolt

(See Torque Specifications)

Carrier Housing

Inner Pinion Bearing Cup

Inner Pinion Bearing Cone

Oil Slinger Seal

Pinion Oil Slinger (Selective)

End Yoke Assembly

Pinion Oil Seal

Outer Pinion Bearing Cone

Carrier Mounting Bolt

(See Torque Specifications)

Washer

Flanged Hex Nut

(700-900 Lb-Ft)

(949-1,220 N-m)

Outer Pinion Bearing Cup

13

5. Use a feeler gauge or shim stock to ensure bearing

cups are completly seated in bearing bores (.0015"

approx.). This is necessary for proper pinion

position.

See Figure 8.

6. Install inner pinion oil slinger seal into the carrier

with the tabs locking into the oil channel. Make

sure the flat side of the seal is seated against the

bottom of the bearing cup bore so that the lip side

will be against the pinion oil slinger.

7. Install pinion into carrier using slow steady move-

ment when sliding through inner bearing cup and

seal. The pinion should be restrained from end

movement by using a retaining strap.

See Figure 9.

1. Assemble the proper pinion position spacer, oil

slinger seal and inner bearing cone onto the pinion.

2. Press pinion pilot bearing

on the pinion.

3. Stake pinion pilot bearing

onto pinion in six places,

using a center punch or

equivalent tool.

See

illustration on right.

NOTE: Make sure all carrier bores are free from all nicks,

dirt, or any other contamination.

4. Install the inner and outer bearing cups into the

carrier.

FFFFFigur

igur

igur

igur

igure 8

e 8

e 8

e 8

e 8

FFFFFigur

igur

igur

igur

igure 9

e 9

e 9

e 9

e 9