Pinion assembly – Spicer Drive Axles Service Manual User Manual

Page 13

11

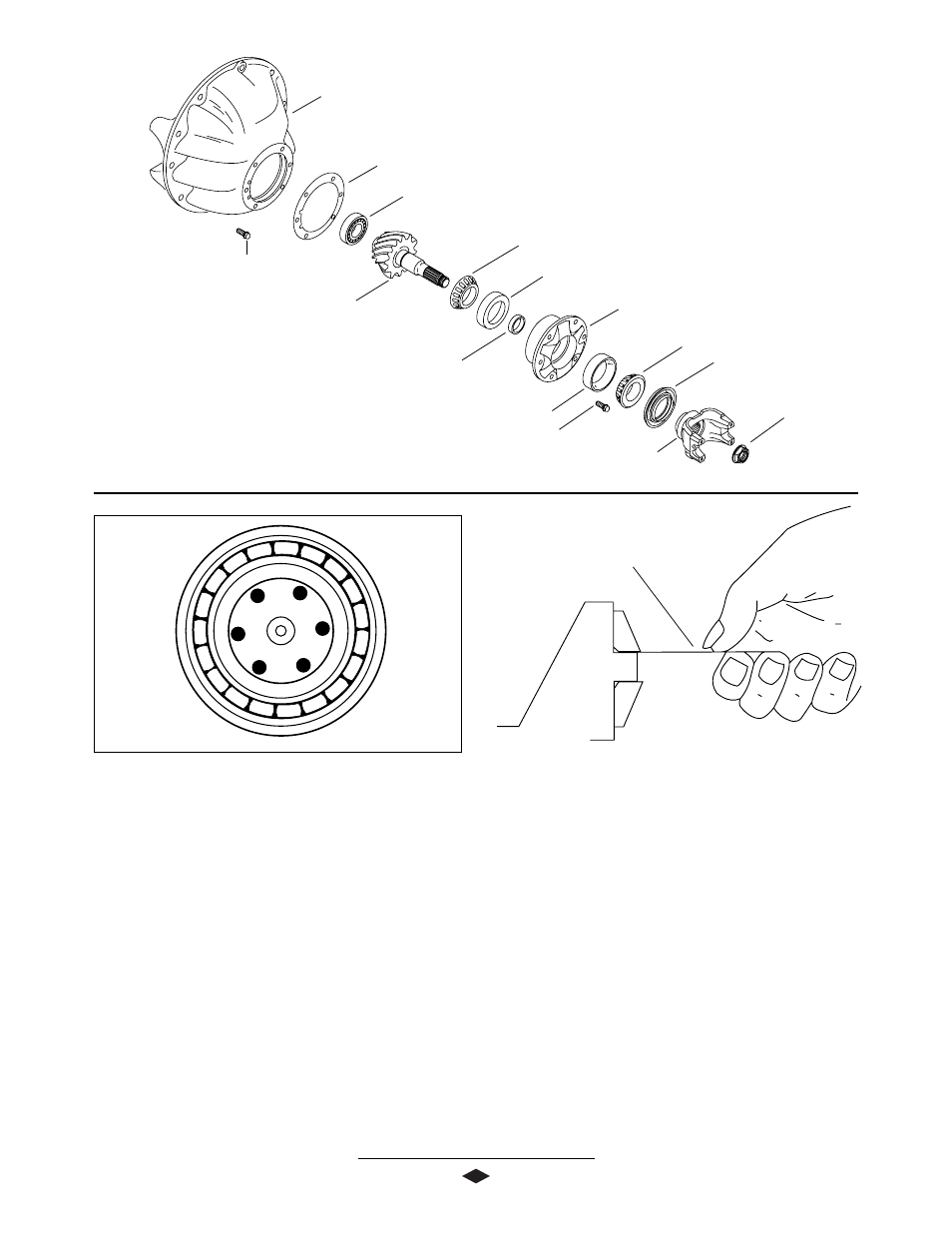

PINION ASSEMBLY

FFFFFigur

igur

igur

igur

igure 7

e 7

e 7

e 7

e 7

1. Press inner pinion bearing cone onto pinion.

2. Press pinion pilot bearing onto nose of pinion.

3. Stake nose of pinion in 6 places, using a center

punch or equivalent tool.

See Figure 7.

4. Install inner pinion bearing cup into pinion bearing

cage.

5. Install outer pinion bearing cup into pinion bearing

cage.

6. Use a feeler gauge or shim stock (.0015 Approx.) to

ensure bearing cups are completely seated in

bearing bores. This is necessary for proper pinion

position.

7. Place pinion bearing spacer, that was removed during

disassembly, onto pinion.

8. Place pinion bearing cage onto inner pinion bearing

cone.

9. Install outer pinion bearing cone and washer on to

pinion.

10. Inspect end yoke or flange for grooves in seal

surface caused by contaminants. If grooves can

be detected with fingernail, then end yoke must be

repaired with a CR approved repair sleeve replaced.

11. Install end yoke onto pinion without seal, to allow

proper setting of bearing preload. Torque pinion nut

to 700-900 Lb-Ft (950-1,220 N-m)

See Figure 8.

Feeler Gauge

Carrier Housing

Carrier Mounting Bolt

(100-120 Lb-Ft)

(136-162 N-m)

Inner Pinion Bearing Cup

Pinion Position Shim(s)

Outer Pinion Bearing Cone

Pinion Bearing Cage

Pinion Oil Seal

Flanged Hex Nut

(700-900 Lb-Ft)

(950-1,220 N-m)

End Yoke Assembly

Outer Pinion Bearing Cup

Inner Pinion

Bearing Cone

Pinion

Pinion Pilot Bearing

Pinion Bearing Cage Bolts

(160-180 Lb-Ft)

(217-244 N-m)

Bearing Preload Spacer