Cleaning and inspection – Spicer Drive Axles Service Manual User Manual

Page 12

10

CLEANING AND INSPECTION

DRYING

INSPECTION

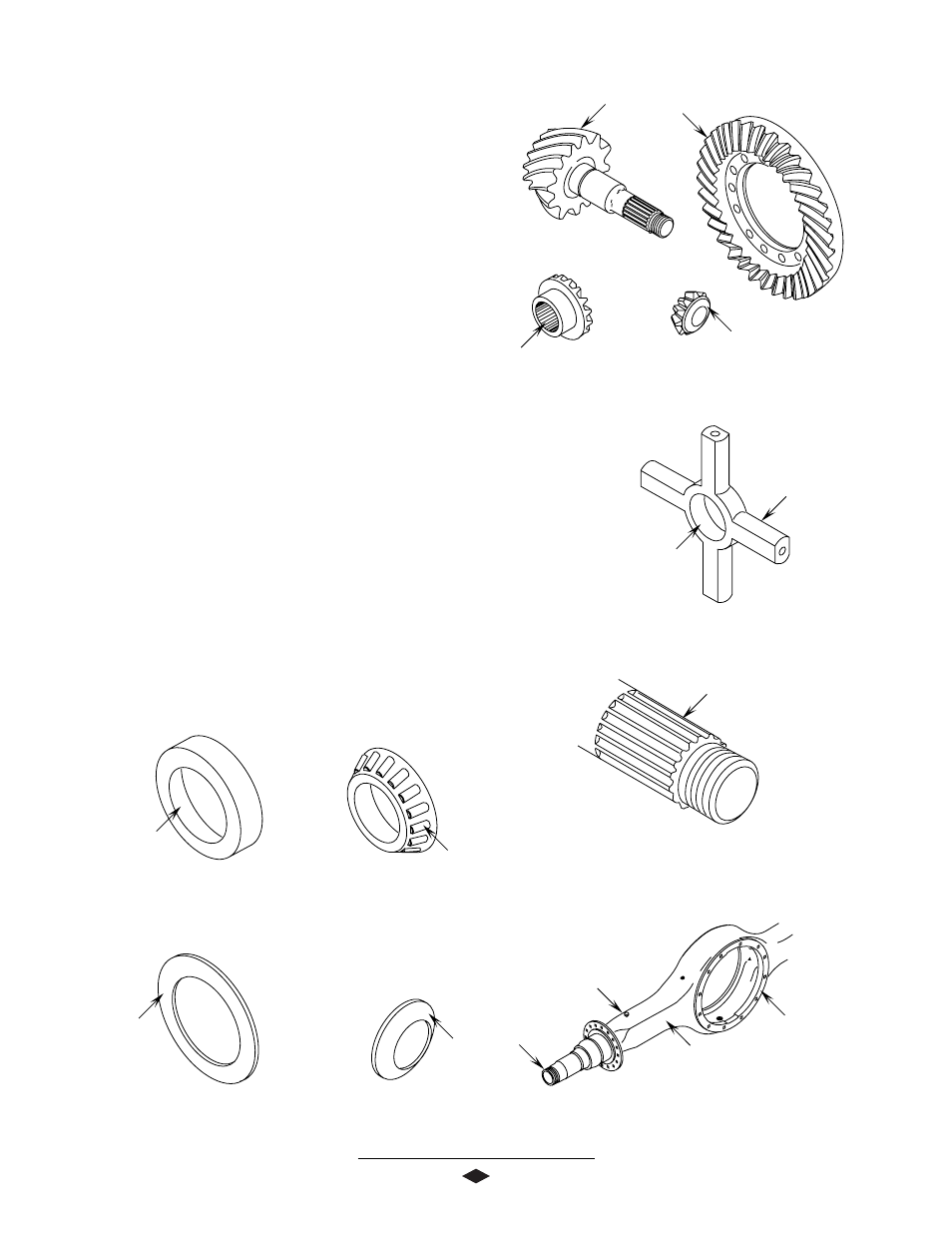

GEARS

SPLINES

1 . Parts should be cleaned with emulsion cleaners or pe-

troleum base cleaning solvent.

Use soft, clean, lintless towels or rags to dry components

after cleaning. Bearings should

not

be dried by spinning

with compressed air. This can damage mating surfaces

due to the lack of lubrication.

After drying, parts should be coated with a light coat of

lubricant or rust inhibitor to prevent damage from

corrosion. If parts are to be stored for a prolonged

period, they should be wrapped in wax paper.

Inspect gears for excessive wear or damage. Replace

gears that are pitted, scored, broken, or worn.

SHAFTS

Inspect shafts for nicks or scoring.

HOUSINGS

Inspect thrust washers for scoring and cracking.

Inspect housing for stripped threads and bending fatigue.

Inspect all splines for excessive wear, distortion from

twisting, and cracking.

BEARINGS

Prior to reassembly, inspect parts for signs of excessive

wear or damage. Replacement of these parts can prevent

premature failure and costly downtime.

Bearing surfaces should be inspected for pitting, excessive

wear, or overheating.

THRUST WASHERS

CLEANING

NOTE: Alkaline type solutions may cause

damage to machined surfaces and should be

avoided.

2 . Make sure interior of axle housing is clean prior to reas-

sembly.

3 . Clean all gasket surfaces of old material.