Pinion above center applications, Differential disassembly, Pinoin above center applications – Spicer Drive Axles Service Manual User Manual

Page 10

IMPORTANT: If any gears are to be replaced, they

must be replaced in sets. Inspect thrust washers for

scoring and excessive wear. Replace all worn or

damaged parts.

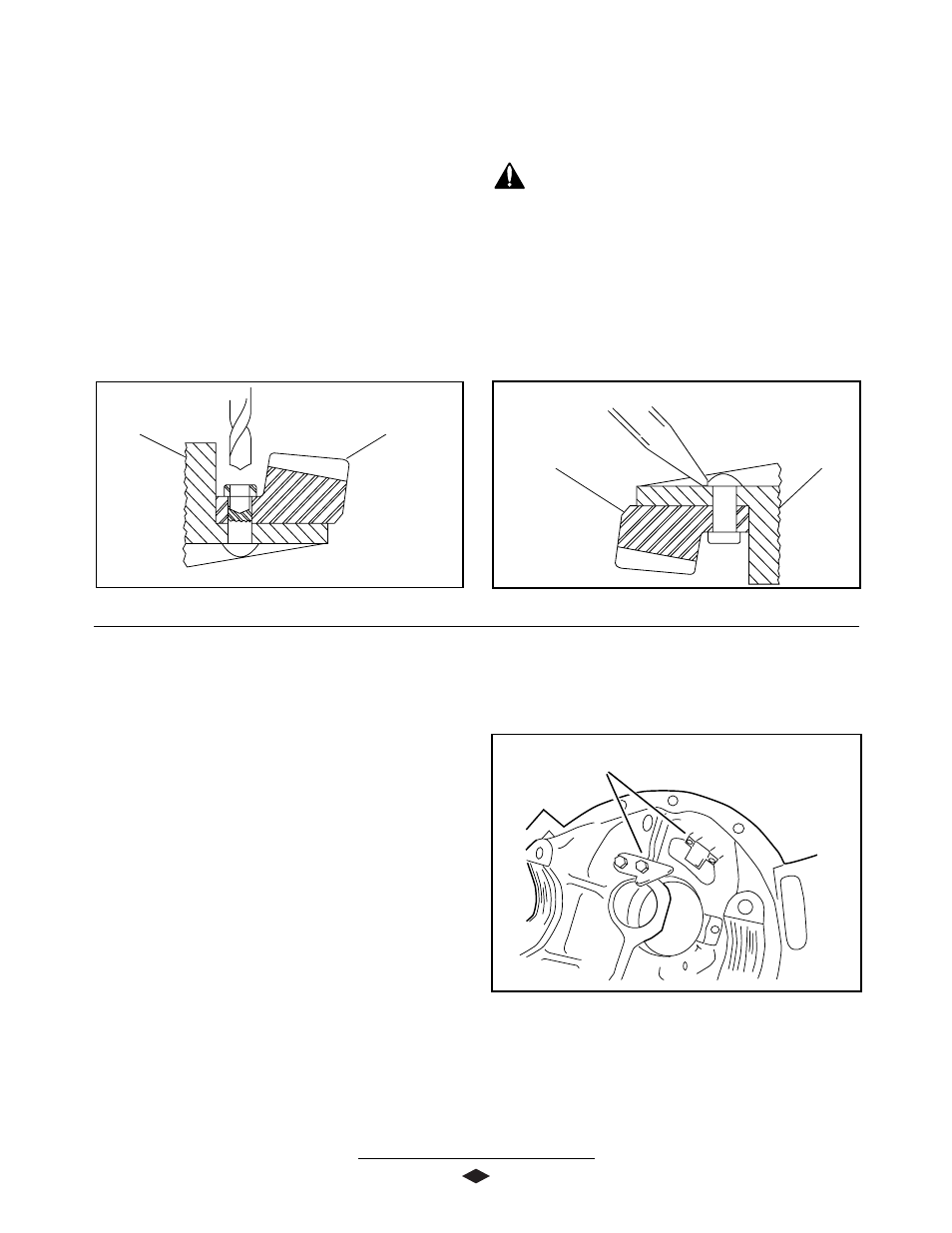

7. When it is necessary to remove ring gear from

differential case, carefully center punch each rivet

head. Use a 9/16" drill bit and drill through rivet

heads.

See Figure 4.

8

CORRECT PROCEDURE

INCORRECT PROCEDURE

DIFFERENTIAL DISASSEMBLY

FFFFFigur

igur

igur

igur

igure 4

e 4

e 4

e 4

e 4

FFFFFigur

igur

igur

igur

igure 5

e 5

e 5

e 5

e 5

8. Next, use a round type punch to drive out the

remaining portion of the rivet.

CAUTION: Always use a soft hammer or H.D.

plastic head hammer to strike punch.

NOTE: Do not use a chisel to remove rivet heads,

damage to differential case may result. See Figure 5.

Differential Disassembly Complete

PINOIN ABOVE CENTER APPLICATIONS

The F155-S and F170-S axle assemblies may be

specified for pinion above center applications, such

as motor homes, buses, or other rear engine chassis

vehicles.

The following modifications to the carrier assemblies

have been made to insure proper lubrication when

axle assembly is mounted with pinion above center.

The F155-S and the F170-S need to have two oil

scoops and an additional oil passage in the pinion

bearing cage, as shown in the illustration to the

right. Mounting screws for the oil scoop must be

cleaned and coated with #271Loctite, or its

equivalent. The 3/8 inch oil scoop mounting bolts

must be tightened to 34-38 Lb-Ft (46-51 N-m)

torque.

See Figure 6.

Case

FFFFFigur

igur

igur

igur

igure 6

e 6

e 6

e 6

e 6

Case

Ring Gear

Ring Gear

Oil Scoops