MSD 6214 Midget DIS-2 Programmable Race Ignition Installation User Manual

Page 5

INSTALLATION INSTRUCTIONS

5

M S D

• W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

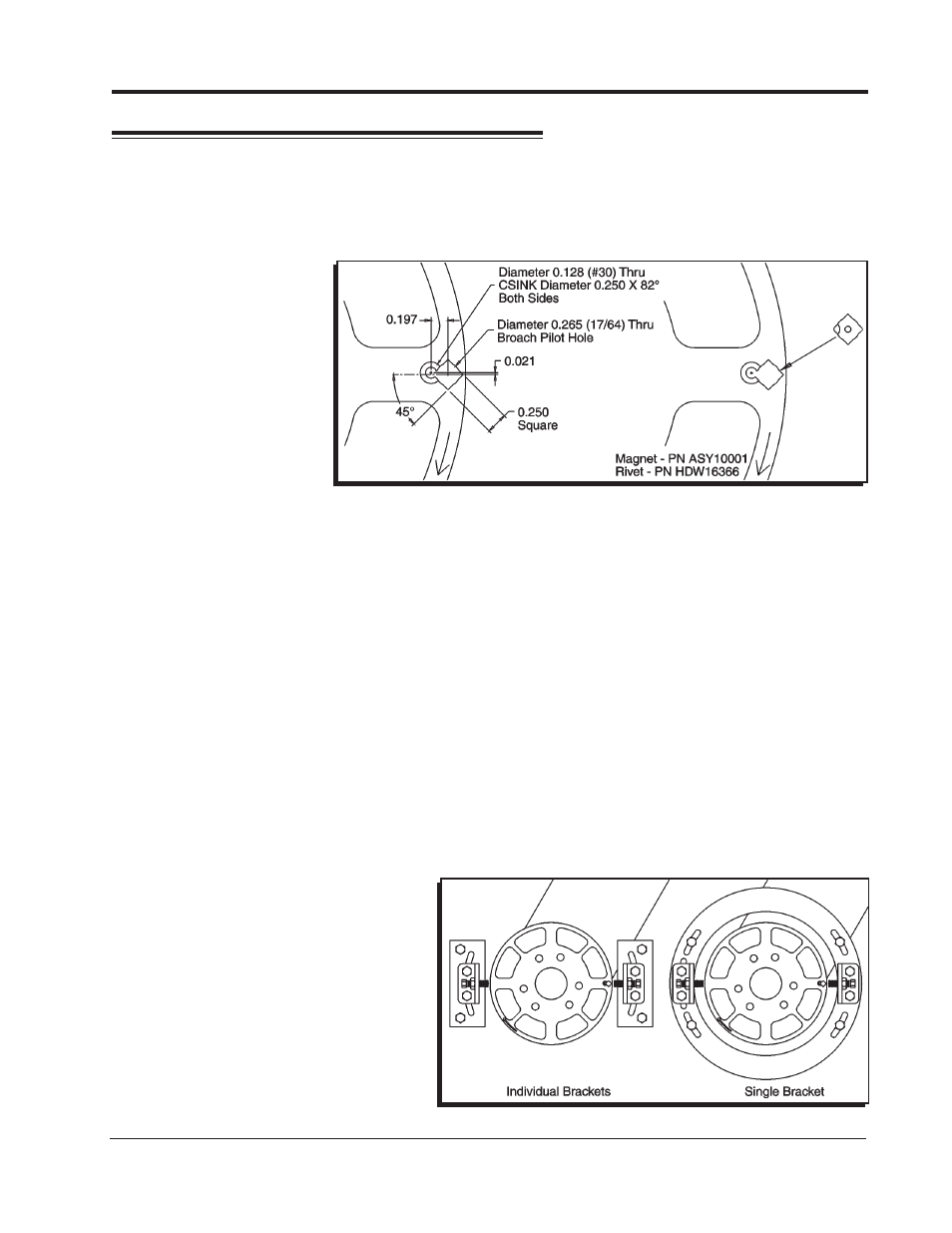

TRIGGER WHEEL FABRICATION

Due to the variety of engines and applications, a crank trigger wheel is not offered and must

be fabricated. The brackets for the two pickups must also be made.

The trigger wheel must be 3/8" thick for the MSD magnet to properly fit. The wheel can by

any type of non-magnetic material (aluminum, non-magnetic stainless, etc...) and can be any

diameter over 4”. MSD offers several trigger wheels for V8 applications that may be modified

for certain applica-

tions.

A magnet is sup-

plied that must

be installed in the

trigger wheel. This

magnet must be

oriented in one po-

sition to produce

the correct trigger

signal for the non

magnetic pickups.

This is detailed in

Figure 2.

1. Place the magnet in the wheel with the hole in the plastic overmolding facing the front of

the motor. The chamfer in the magnet must be positioned next to the hole for the aluminum

rivet.

2. Insert the aluminum rivet. The rivet must be set using a press or a vice with a set of smooth,

parallel jaws (such as the vice on a milling machine).

MOUNTING THE TRIGGER PICKUPS

Since the MSD Programmable Midget Ignition is a two channel, waste spark ignition system

there must be two trigger pickups. Brackets must be fabricated so the pickups are positioned

180° apart. Figure 3 shows two different mounting brackets.

Individual Brackets: Each pickup can be mounted on it’s own individual bracket 180° from

each other. In this configuration both pickups will need to be moved to make timing adjust-

ments. Care will have to be taken to ensure that the pickups remain 180 degrees apart.

One Bracket: By using one bracket to position both pickups, timing adjustments will be easier

to set. The bracket will have to be slotted to make timing adjustments and one pickup will be

fixed and the other one will require adjustment slots to index it 180° from the other. Once the two

pickups are indexed correctly the

entire bracket will be able to be

rotated to make timing changes.

This configuration may be harder

to produce but has the advantage

of easier timing adjustments once

the pickups are indexed.

Figure 2 Mounting the Magnet in the Trigger Wheel.

Figure 3 Trigger Pickup Mounting Examples.