Zebra Technologies S400 User Manual

Page 51

Zebra S400 & S600 User’s Guide

43

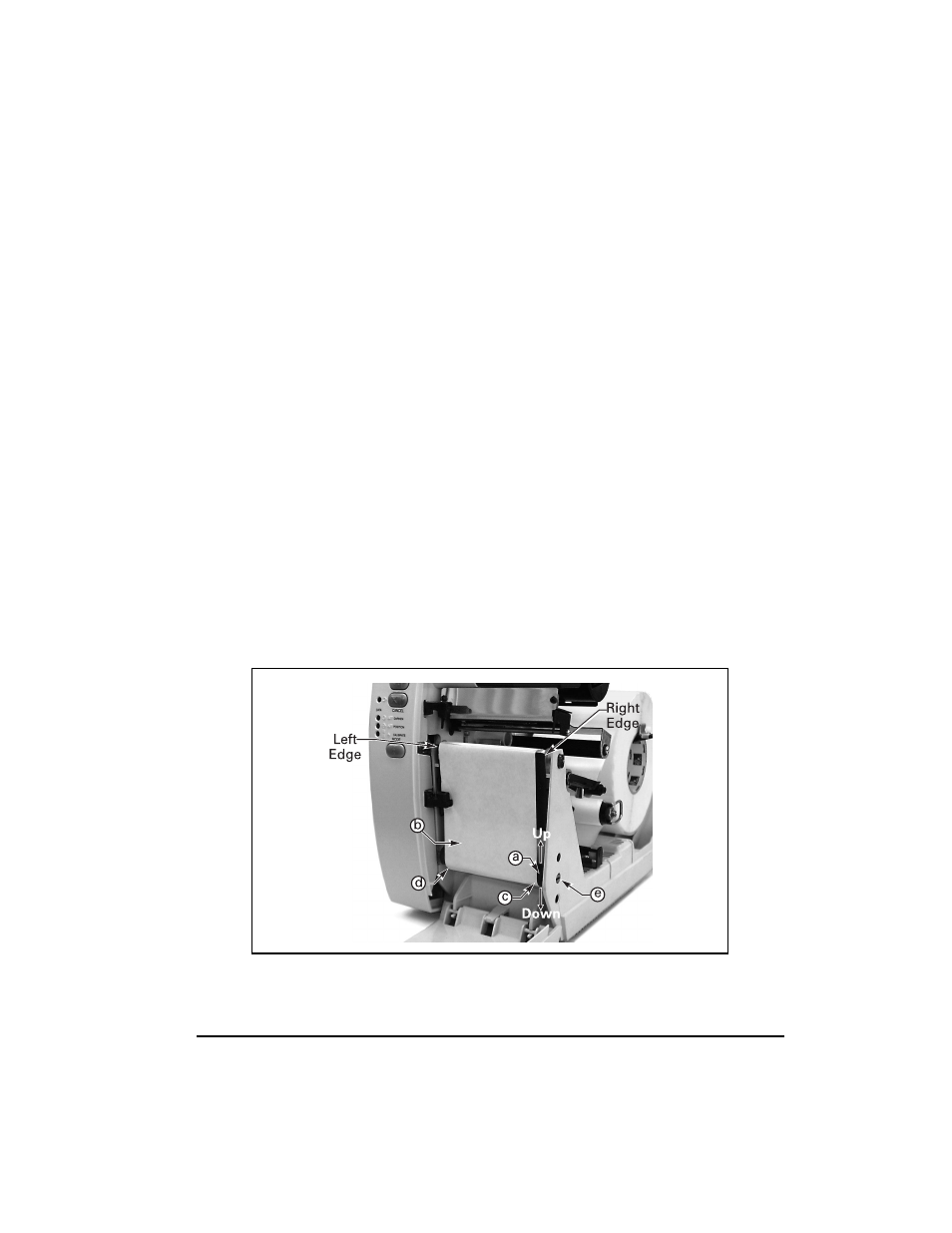

Figure 24 illustrates an improperly adjusted backing rewind power roller

(a). On the left side, the backing material (b) is not contacting the power

roller. The backing has more tension on the right edge (c) than on the left

edge (d).

Use a coin or screwdriver to turn the power roller adjustment (e). The

adjustment mechanism changes the position of the right end of the roller,

while the left end is stationary. The right end moves up and down for

tension balance.

Turning this adjustment in a counterclockwise direction causes the right

end of the power roller to move down and increases the tension on the

right side of the backing material. (Turning the adjustment in a clockwise

direction moves the right end of the power roller up and decreases the

tension on the right side.)

Balancing the tension increases the reliability of the printer to provide

properly printed labels by preventing the label backing from walking.

Use the FEED Key Self Test (see page 59) or your own label format to

print several labels to ensure tracking is maintained and tension on both

edges of the backing material remains consistent. Remember to remove

each label as it is automatically peeled away from the backing.

Figure 24. Improper Backing Rewind Power Roller Adjustment