Routine care and adjustments, Cleaning, Øïlí aãlíací cøæïlïæ – Zebra Technologies S400 User Manual

Page 35: Ohdqlqj

Zebra S400 & S600 User’s Guide

27

/ØÏlÍ AÃlÍAcÍ cØÆÏlÏÆ

&OHDQLQJ

CAUTION: Use only the cleaning agents indicated below.

Zebra Technologies Corporation will not be responsible for

any other products being used on this printer. No lubricants

are needed.

Table 1 provides a brief cleaning schedule. Specific cleaning procedures

are provided on the following pages. Cleaning swabs saturated with 70%

isopropyl alcohol are available from your distributor as a preventive

maintenance kit.

Refer to Figure 15 for cleaning locations.

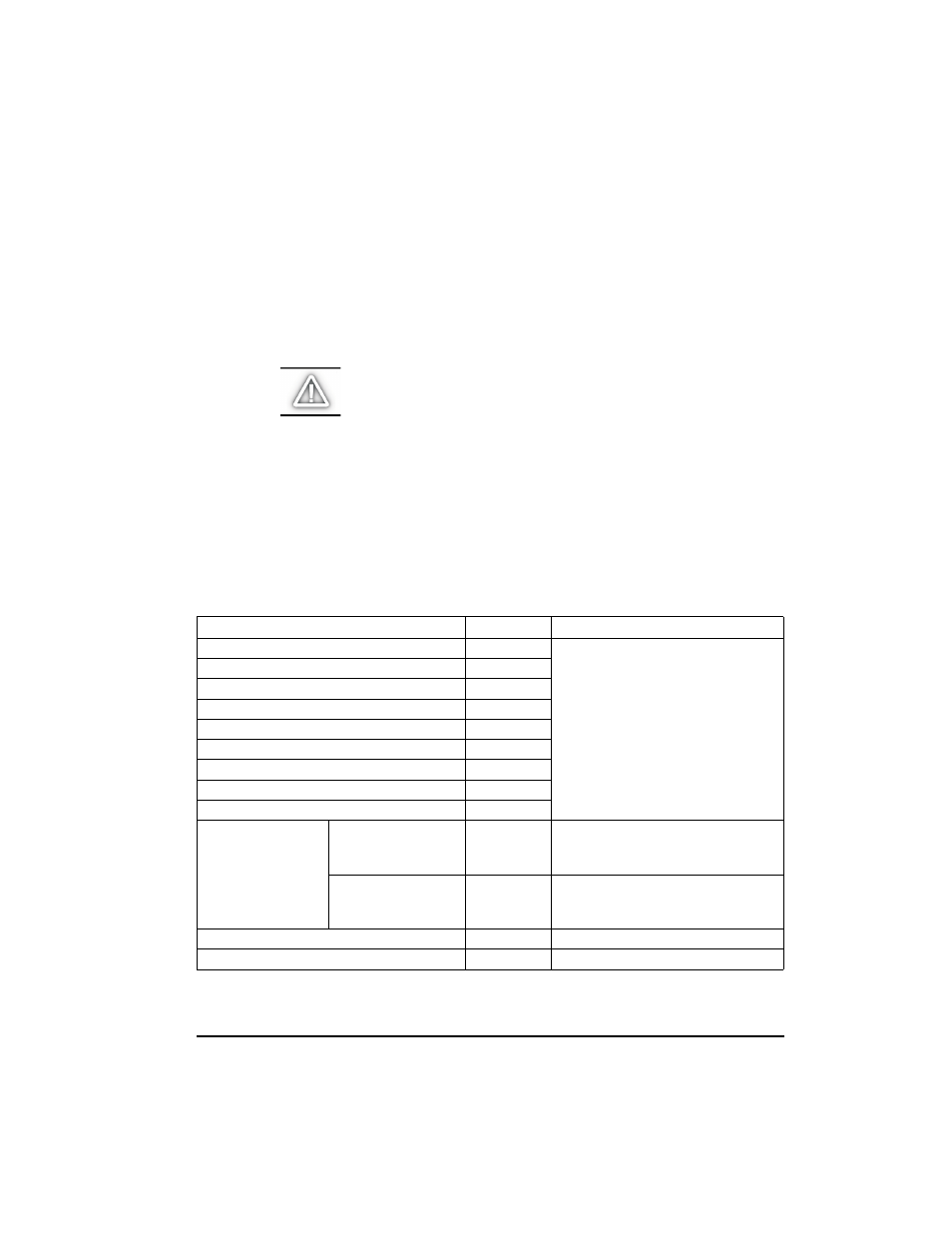

Table 1. Cleaning Schedule

Area

Method

Interval

Printhead (a)

Alcohol

After every roll of media (or 500 feet

of fanfold media) when printing in

the direct thermal mode.

After every roll of ribbon when

printing in the thermal transfer

mode.

Platen roller (b)

Alcohol

Media sensor (c)

Air blow

Media path (d)

Alcohol

Ribbon path (e)

Air blow

Upper guide rod (f) (Peel-Off)

Alcohol

Platen guide rod (g) (Peel-Off)

Alcohol

Rewind power roller (h) (Peel-Off)

Alcohol

Lower guide rod (i) (Peel-Off)

Alcohol

Cutter Assembly (j)

(if used)

Cutting continuous,

pressure-sensitive

media

Citrus based

adhesive

remover

After every roll of media or more

often, depending upon your

application and the media.

Cutting tagstock or

label backing

material only

Alcohol and

air blow

After every 2 or 3 rolls of media.

Tear-Off/Peel-Off plate (k)

Alcohol

Once a month.

Label available sensor (l)

Air blow

Once every six months.