Image quality, Billing meters and accounting, Automatic tray switching (load-while-run) – Xerox 4112 User Manual

Page 15

15

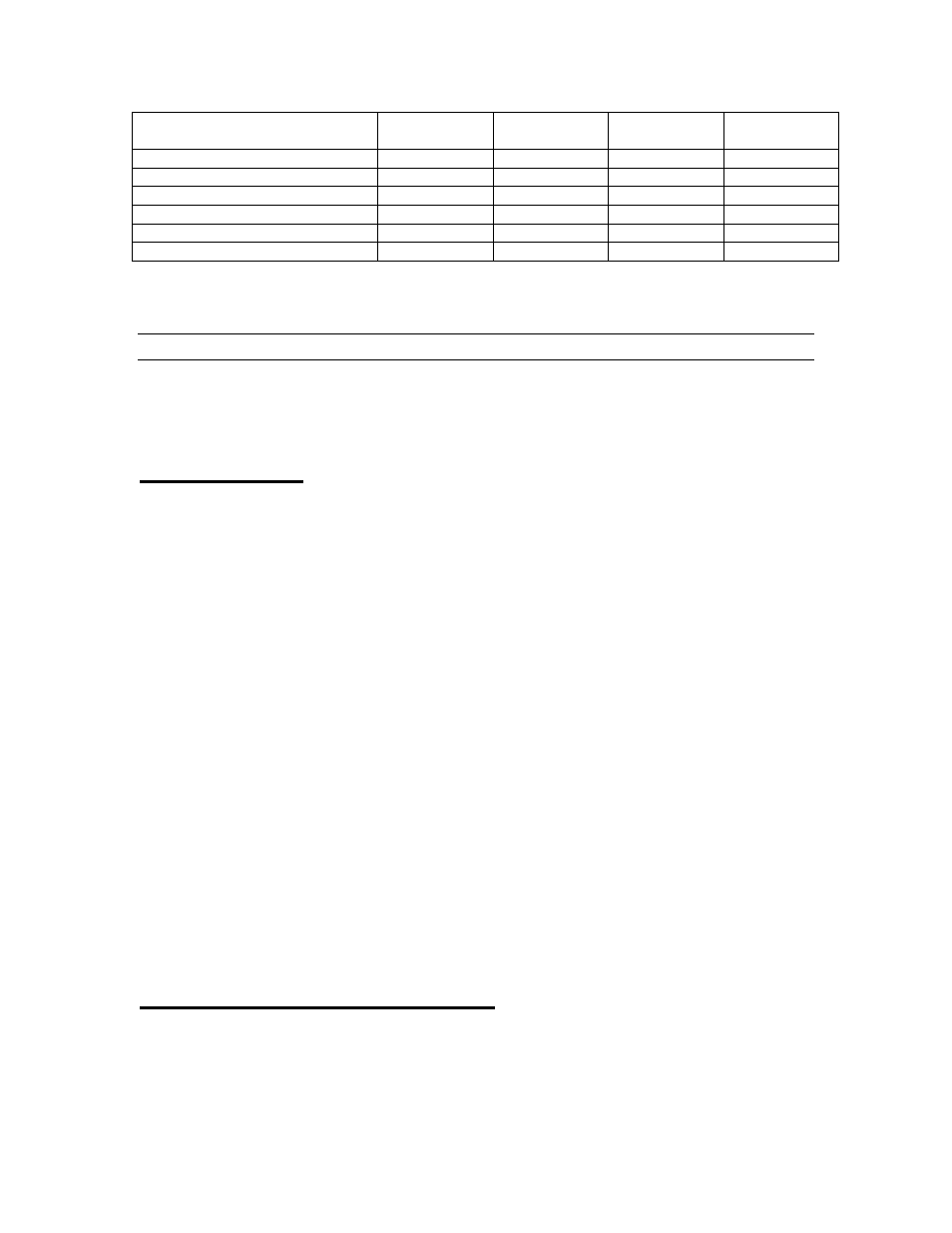

Paper Size

125 ppm

Simplex

125 ppm

Duplex

*3

110 ppm

Simplex

110 ppm

Duplex

*3

B5

LEF

125 125 116 105

A4 LEF / 8.5x11 LEF

125

125

110

100

*2

B5 SEF / A4 SEF / 8.5x11 SEF

*1

88

80

*2

78 70

*2

B4 SEF / 8.5x14 / 8.5x13 SEF

*1

78

70

*2

69 69

A3 SEF / 11x17 SEF

*1

62 62 55 55

12 x 18 SEF / 12 x 19.2 SEF

*1

34 34 34 34

*1: Only Tray 3 and Tray 4 can be used.

*2: For second output sheet onward, IPM is equal to the CPM in simplex printing.

*3: IPM: Impression Per Minutes

Automatic Tray Switching (Load-While-Run)

The paper trays support Load-While-Run operation. If a tray in operation runs out of stock, and

another tray with the same programmed stock is available and loaded, the system will

automatically switch to the new tray when the first runs out. The operator may then open the

empty tray and reload it without the system stopping.

Image Quality

• Image quality perception is subjective and will be affected by ambient lighting conditions.

• Like other reproduction processes, there will be some variation of output quality over

time. For example: long runs, with high area coverage. Factors contributing to this can

include frequency of service and xerographic components.

• Image quality is strongly influenced by paper surface structure, texture, and color. To

ensure that your customers are optimally satisfied, key applications should be printed

using representative paper and reviewed by the customer.

• The surface texture of some uncoated papers may cause increased graininess in

halftone areas printed with toner. This effect may be minimized by using smooth or

coated papers (refer to the Recommended Materials List).

• Sheets of a job may exhibit slight gloss differential and oil streaks from page to page.

Operational mode will have an impact on the level of gloss differential.

• Prints may exhibit random white spots caused by paper dust, stray developer beads, or

other miscellaneous particles. You can reduce the occurrence of white spots by using

Xerox approved paper. If customers are cutting their own paper, ensure that cut edges

are dust free, and keep the machine in a clean and dust/dirt reduced environment.

Failure to do this will result in increased frequency of white spots.

• As with any printing process, artifacts will occur. These include streaks, mottle, banding,

spots, etc. For most jobs and clients, the expected level of artifacts is within the normal

operational and component quality ranges of the system and will not affect the

acceptability of the job. Maintenance procedures are available to mitigate these artifacts.

Random artifacts will occur. Artifact-sensitive jobs should be monitored. Using products

on the recommended by your Xerox Supplies Specialist and maintaining your

environment will also help to minimize the occurrence of these artifacts.

• Environmental factors such as very high or very low humidity effects image quality. See

the Environmental Requirements section of this document for guidelines.

Billing meters and accounting

The product provides accurate billing of all prints through the electronic billing meter within the

printer system. There is no mechanical meter on the printer system. Meters can be accessed and

read from the user interface on the printer.

- 4112-4127 Enterprise Printing System-190 4112-4127 Enterprise Printing System-4619 4112-4127 Enterprise Printing System-6663 4112-4127 Enterprise Printing System-3366 4112-4127 Enterprise Printing System-209 4112-4127 Enterprise Printing System-6682 4112-4127 Enterprise Printing System-3385 4112-4127 Enterprise Printing System-4638