Gas piping, Fig. 3 - typical field wiring, Table 3 - pipe sizing – York SUNLINE PLUS D2EG 048 User Manual

Page 5

DISCONNECT SWITCH BRACKET FOR UNITS

WITH OPTIONAL BELT-DRIVE BRACKET

A special bracket for mounting a field-supplied disconnect

switch is provided in each unit ordered with an optional belt-

drive supply air blower. The bracket is shipped inside the

blower compartment taped to the top of the blower housing.

Install the bracket on the left hand side of the unit as shown in

Figure 9. Several existing screws at the top of the unit and one

approximately midway down from the top will be used for

mounting the bracket. Screws should be loosened only - NOT

REMOVED. Mounting holes in the bracket have elongated

keyways allowing easy installation. Re-tighten screws after

bracket is in place to ensure panels will remain leak tight.

GAS PIPING

Proper sizing of gas piping depends on the cubic feet per hour

of gas flow required, specific gravity of the gas and the length of

run. “National Fuel Gas Code” Z223.1 should be followed in all

cases unless superseded by local codes or gas company

requirements. Refer to Table 3.

The heating value of the gas may differ with locality. The value

should be checked with the local gas utility.

NOTE: There may be a local gas utility requirement specifying

a minimum diameter for gas piping. All units require a

1/2 inch pipe connection at the entrance fitting.

035-14832-003-A-0204

Unitary Products Group

5

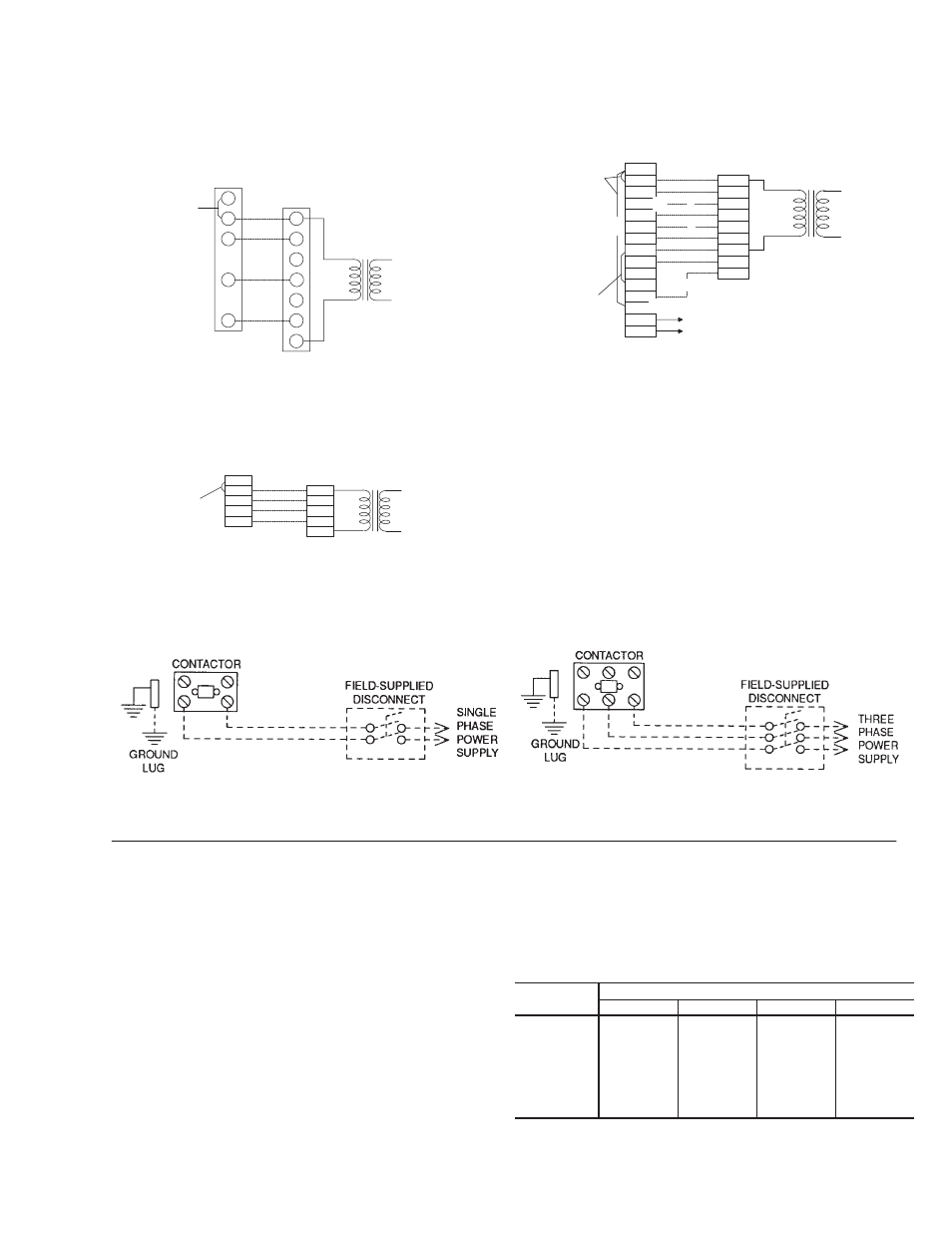

FIG. 3 - TYPICAL FIELD WIRING

REFER TO THE ELECTRICAL

DATA TO SIZE THE DISCONNECT

SWITCH, THE WIRING AND THE

OVERCURRENT PROTECTION

REFER TO THE ELECTRICAL

DATA TO SIZE THE DISCONNECT

SWITCH, THE WIRING AND THE

OVERCURRENT PROTECTION

POWER WIRING

Length in Feet

Nominal Iron Pipe Size

1/2 in.

3/4 in.

1 in.

1-1/4 in.

10

20

30

40

50

60

70

80

90

100

132

92

73

63

56

50

46

43

40

38

278

190

152

130

115

105

96

90

84

79

520

350

285

245

215

195

180

170

160

150

1,050

730

590

500

440

400

370

350

320

305

Maximum capacity of pipe in cubic feet of gas per hour. (Based upon a pressure drop of 0.3 inch

water column and 0.6 specific gravity gas).

TABLE 3 - PIPE SIZING

CONTROL WIRING

R C

Y

R

Y 1

Y 2

W 1

W

W 2

G

B

G

R H

T H E R M O S T A T

1

T E R M I N A L S

U N I T T E R M I N A L

S T R I P T B 1

2 4 V O L T

T R A N S F O R M E R

C O O L I N G / H E A T I N G ( 2 4 V O L T T H E R M O S T A T )

1

2 4 V O L T T H E R M O S T A T 2 T H 0 7 7 0 1 0 2 4 . I F T H E U N I T H A S A N E C O N O M I Z E R ,

R E M O V E J U M P E R J 1 F R O M T E R M I N A L S 8 A N D 1 0 O N T H E R E L A Y B O A R D

T O P R E V E N T S I M U L T A N E O U S O P E R A T I O N O F T H E C O M P R E S S O R A N D

T H E E C O N O M I Z E R . I F Y O U W A N T T O C O N T R O L T H E R E C O N O M I Z E R O N A

S E C O N D S T A G E O F C O O L I N G O R H A V E A N D E L E C T R I C H E A T A C C E S S O R Y

W I T H T W O S T A G E S O F H E A T , U S E T H E R M O S T A T 2 T H 0 4 7 1 0 2 4

A D D

J U M P E R

COOLING / HEATING (24 VOLT THERMOSTAT)

R C

R H

Y 1

Y 2

W 1

W 2

G

L E D 1

L E D 2

C O M

A 1

A 2

T

T

B

R

Y 1

Y 2

G

B

X

N

W 2

W 1

T H E R M O S T A T

1

T E R M I N A L S

U N I T T E R M I N A L

S T R I P T B 1

2 4 V O L T

T R A N S F O R M E R

T O R E M O T E S E N S O R

2 T H 0 4 0 7 0 2 2 2 4 I F U S E D

N O T

U S E D

A D D

J U M P E R

A D D

J U M P E R

4

4

3

2

1

E L E C T R O N I C P R O G R A M M A B L E T H E R M O S T A T 2 E T 0 4 7 0 0 2 2 4 ( I N C L U D E S S U B B A S E )

2

S E C O N D S T A G E C O O L I N G I S N O T R E Q U I R E D O N U N I T S L E S S E C O N O M I Z E R .

3

S E C O N D S T A G E H E A T I N G I S O N L Y R E Q U I R E D O N U N I T S W I T H A T W O S T A G E

E L E C T R I C H E A T E R .

4

R E M O V E J U M B E R J 2 F R O M T E R M I N A L S 4 A N D 9 O N J U M P E R P L U G C O N N E C T O R

P 6 O N U N I T S W I T H E C O N M I Z E R . T E R M I N A L S A 1 A N D A 2 P R O V I D E A R E L A Y

O U T - P U T T O C L O S E T H E O U T D O O R E C O N O M I Z E R D A M P E R S W H E N T H E

T H E R M O S T A T S W I T C H E S T O T H E S E T - B A C K P O S I T I O N .

COOLING / HEATING (ELECTRONIC THERMOSTAT)

2

3

R H

R C

Y

W

G

R

Y 1

W 1

B

G

A D D

J U M P E R

T H E R M O S T A T

1

T E R M I N A L S

U N I T T E R M I N A L

S T R I P T B 1

2 4 V O L T

T R A N S F O R M E R

1

E L E C T R O N I C P R O G R A M M A B L E T H E R M O S T A T 2 E T 0 7 7 0 1 0 2 4 ( I N C L U D E S S U B B A S E ) .

I F T H I S U N I T H A S A N D E C O N O M I Z E R , R E M O V E J U M P E R J 1 F R O M T E R M I N A L S 8 A N D

1 0 O N T H E R E L A Y B O A R D T O P R E V E N T S I M U L T A N E O U S O P E R A T I O N O F T H E

C O M P R E S S O R A N D T H E E C O N O M I Z E R . I F Y O U W A N T T O C O N T R O L T H E

E C O N O M I Z E R O N A S E C O N D S T A G E O F C O O L I N G , U S E T H E R M O S T A T 2 E T 0 4 7 0 0 2 2 4 .

C O O L I N G / H E A T I N G ( E L E C T R O N I C T H E R M O S T A T )

S I N G L E S T A G E