York SUNLINE PLUS D2EG 048 User Manual

Page 15

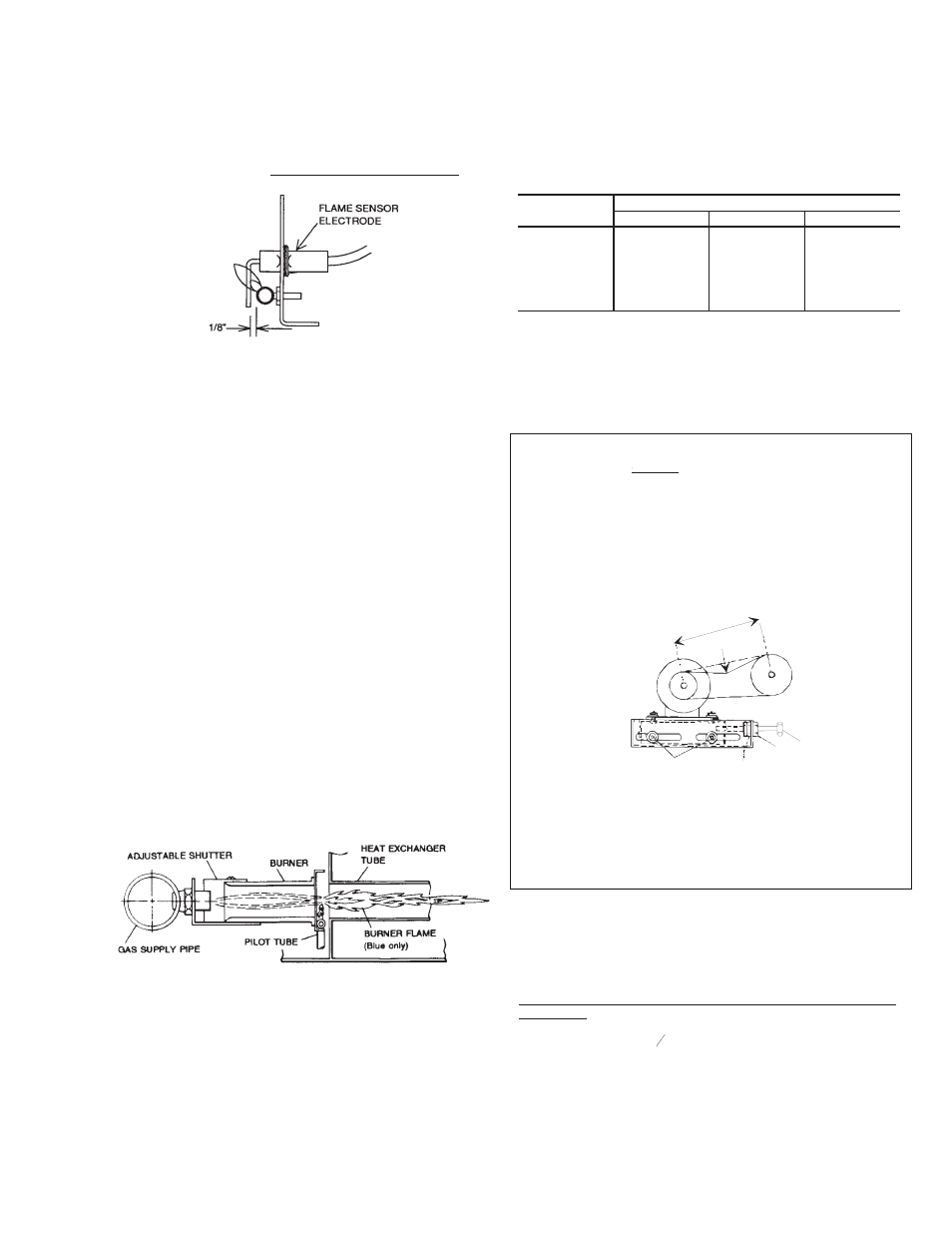

PILOT CHECKOUT

The pilot flame should envelope 3/8 inches of the end of the

flame sensor. Refer to Figure 12. To adjust pilot flame, (1)

remove pilot adjustment cover screw, (2) adjust the screw for

the proper pilot flame, (3) be sure to replace cover screw after

adjustment to prevent possible gas leakage.

Put the system into operation and observe through complete

cycle to be sure all controls function properly.

BURNER INSTRUCTIONS

To check or change burners, pilot or orifices, CLOSE MAIN

MANUAL SHUT-OFF VALVE AND SHUT OFF ALL POWER

TO THE UNIT.

1. Remove the two screws holding either end of the manifold

to the burner supports.

2. Open the union fitting in the gas supply line just upstream of

the unit gas valve and downstream from the main manual

shut-off valve.

3. Remove the gas piping patch plate.

4. Disconnect wiring to the gas valve and spark ignitor.

Remove the manifold-burner gas valve assembly by lifting

up and pulling back.

Burners are now accessible for service.

Reverse the above procedure to replace the assembly. Make

sure that burners are level and seat at the rear of the heat

exchanger.

BURNER AIR SHUTTER ADJUSTMENT

Adjust burner shutters so that a distinct, sharp, blue flame is

obtained. Refer to Figure 13.

SUPPLY AIR AIR BLOWER AND TEMPERATURE

RISE ADJUSTMENTS

The speed of the supply air blower will depend on the required

CFM, the unit accessories and the static resistances of both the

supply and the return air duct systems. With this information,

the speed for the supply air blower can be determined from the

blower performance and accessory static resistance data in

Table 5 through 8.

Knowing the required blower RPM and the blower motor HP,

the speed setting for the supply air motor can be determined.

The setting (turns open) for the optional belt-drive supply air

motor pulley can be determined from Table 13.

OPTIONAL BELT-DRIVE BLOWER

All units with belt-drive blowers have single speed motors. The

variable pitch pulley on the blower motor can be adjusted to

obtain the desired supply air CFM. Refer to Table 9 for blower

motor and drive data. The tension on the belts should be

adjusted as shown in Figure 14.

Start the supply air blower motor. Adjust the resistances in both

the supply and the return air duct systems to balance the air

distribution throughout the conditioned space. The job

specifications may require that this balancing be done by

someone other than the equipment installer.

To check the supply air CFM after the initial balancing has been

completed:

1. Remove the (two)

#

$

" dot plugs from the holes located on

the filter access panel side of the unit.

2. Insert at least 8" of 1/4 inch tubing into each of these holes

for sufficient penetration into the air flow on both sides of

the evaporator coil.

Unitary Products Group

15

035-14832-003-A-0204

FIG. 12 - PROPER FLAME ADJUSTMENT

FIG. 13 - TYPICAL FLAME APPEARANCE

TURNS

OPEN*

BLOWER DRIVE RANGE (RPM)

3 TON

4 TON

5 TON

5

4

3

2

1

0

780

842

904

966

1028

1090

790

856

922

988

1054

1120

850

924

998

1072

1246

1220

*

Pulley can be adjusted in half-turn increments.

TABLE 13 - BELT-DRIVE SUPPLY AIR

MOTOR PULLEY ADJUSTMENT

SPAN LENGTH

DEFL FORCE

* NEVER LOOSEN

(A)

(C)*

(D)

CAUTION

Procedure for adjusting belt tension:

1. Loosen nut (D) from the motor mount.

2. Never loosen nuts (C) from each other while loosening nut (D).

3. Adjust the tension by turning bolt (B).

4. Do not loosen the four nuts (top and bottom) (A); unless additional tensioning

distance is required; immediately re-tighten these bolts if loosened.

5. Use a belt tension checker to apply a perpendicular force to one belt at the

midpoint of the span as shown. The deflection force should be applied

until a specific deflection distance of 4mm (5/32")is obtained. To determine

the deflection distance from normal position, use a straight edge from

sheave to sheave as a reference line. The recommended deflection force

is as follows:

Tension new belts at the max. deflection force recommended for the belt

section. Check the belt tension at least two times during the first 24 hours of

operation. Any re-tensioning should fall between the min. and max.

deflection force values.

6. After adjusting, re-tighten nut (D) against the motor mount taking care not

to loosen nuts (C).

(B)

FIG. 14 - BELT ADJUSTMENT