Start-up – York SUNLINE PLUS D2EG 048 User Manual

Page 14

SAFETY CONTROLS (Heating)

The control circuit includes the following safety controls:

1. Limit Control (LS). This control is located inside the heat

exchanger compartment and is set to open at the

temperature indicated in Table 12. It resets automatically.

The limit switch, operates when a high temperature

condition, caused by inadequate supply air flow occurs,

thus shutting down the ignition control and closing the main

gas valve.

2. Centrifugal Switch (CS-36). If the draft motor should fail,

the centrifugal switch attached to the shaft of the motor

prevents the ignition control and gas valve from being

energized.

3. Redundant Gas Valve. This valve is an integral part of the

main gas valve and is located up stream of the main gas

valve. Should the main gas valve fail in the open position

the redundant valve serves as a back up and shuts off the

flow of gas.

4. Flame Sensor Rod. This sensor rod is located on the far

side of the carryover tube. If the ignition control does not

receive a signal from the flame sensor indicating that the

pilot flame has ignited properly, the main gas valve will not

open. If the flame sensor fails to detect the pilot flame

during operation of the main burners, a signal is sent to the

ignition control to close the main gas valve.

5. Rollout Switch. This switch is located in the burner

vestibule. In the event of a sustained main burner flame

rollout, it shuts off the ignition control and closes the main

gas valve.

6. Auxiliary Limit Switch. This control is located inside the

heat exchanger compartment and is set to open at 180°F. It

is a manual reset switch. If the auxiliary limit switch trips,

then the primary limit switch has not functioned properly.

Replace the primary limit switch.

HEAT ANTICIPATOR SETPOINTS

The anticipator must be set at 0.1 amps. Too high of a setting

will result in longer heat cycles and a greater temperature

swing in the conditioned space.

Reducing the value below the correct setpoint will give shorter

“ON” cycles and may result in the lowering of the temperature

within the conditioned space.

PRE-START CHECK LIST

Complete the following checks before starting the unit.

1. Check the type of gas being supplied. Be sure that it is the

same as listed on the unit nameplate.

2. Make sure that the vent and combustion air hoods have

been properly installed.

14

Unitary Products Group

035-14832-003-A-0204

Units

(Tons)

Capacity, MBH

Limit Control

Opens, °F

Input

Output

3

4

3

4

5

5

50

75

100

125

100

125

40

60

79

99

79

99

165

165

165

165

165

165

TABLE 12 - LIMIT CONTROL SETTING

OPERATING INSTRUCTIONS

CAUTION: This furnace is equipped with an intermittent pilot

and automatic re-ignition system. DO NOT attempt

to manually light the pilot.

TO LIGHT PILOT AND MAIN BURNERS:

1. Turn “off” electric power to unit.

2. Turn room thermostat to lowest setting.

3. Turn gas valve knob to “on” position.

4. Turn “on” electric power to unit.

5. Set room thermostat to desired temperature.

(If thermostat “set” temperature is above room temperature,

pilot burner ignition will occur and, after an interval to prove

pilot flame, main burners will ignite).

TO SHUT DOWN:

1. Turn “off” electric power to unit.

2. Depress knob of gas valve while turning to “off” position.

POST-START CHECK LIST (GAS)

After the entire control circuit has been energized and the

heating section is operating, make the following checks:

1. Check for gas leaks in the unit piping as well as the supply

piping.

2. Check for correct manifold gas pressures. See “Checking

Gas Input”.

3. Check the supply gas pressure. It must be within the limits

shown on rating nameplate. Supply pressure should be

checked with all gas appliances in the building at full fire. At

no time should the standby gas line pressure exceed 13",

nor the operating pressure drop below 4.5" for natural gas

units. If gas pressure is outside these limits, contact the local

gas utility for corrective action.

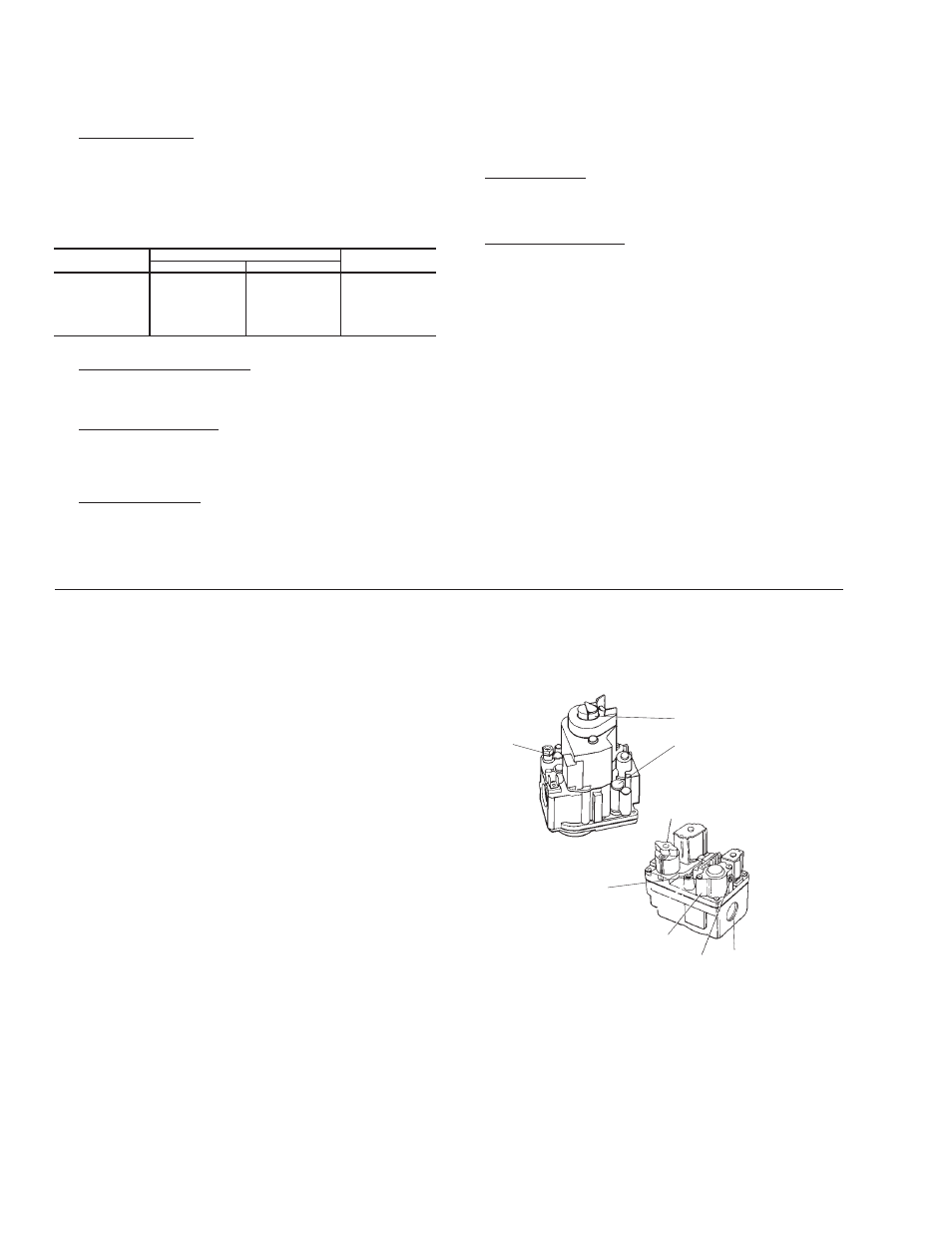

MANIFOLD GAS PRESSURE ADJUSTMENT

Small adjustments to the high-fire gas flow may be made by

turning the pressure regulator adjusting screw on the automatic

gas valve. Refer to Figure 11.

Adjust as follows:

1. Remove the cap on the regulator. (High Fire adjusting screw

on valve).

2. To decrease the gas pressure, turn the adjusting screw

counterclockwise.

3. To increase the gas pressure, turn the adjusting screw

clockwise.

NOTE: Check the unit dataplate for the proper manifold pres-

sure and orifice size of the furnace.

START-UP

PILOT ADJ.

(UNDER

SCREW)

“ON”-"OFF"

CONTROL

HIGH FIRE ADJ.

(UNDER SCREW)

Honeywell

VR8204M

“ON”-"OFF" CONTROL

PRESSURE REGULATOR

MANIFOLD ADJUST. SCREW

1/2-14 NPT (OUTLET)

White-Rodgers

36E36

PILOT ADJ.

(UNDER

SCREW)

FIG. 11 - GAS VALVES