York SUNLINE PLUS D2EG 048 User Manual

Page 4

The supply and return air duct systems should be designed for the

CFM and static requirements of the job. They should NOT be

sized to match the dimensions of the duct connections on the unit.

CAUTION: When fastening ductwork to the side duct flanges on

the unit, insert the screws through the duct flanges

only. DO NOT insert the screws through the casing.

Outdoor ductwork must be insulated and waterproofed.

Refer to Figure 9 for information concerning side and bottom

supply and return air duct openings.

FILTERS

1" filters are supplied with each unit. 2" replacement filters may

be used with no modification to the filter racks. Filters must

always be installed ahead of the evaporator coil and must be

kept clean or replaced with same size and type. Dirty filters will

reduce the capacity of the unit and will result in frosted coils or

safety shutdown. Minimum filter area and required sizes are

shown in Table 4.

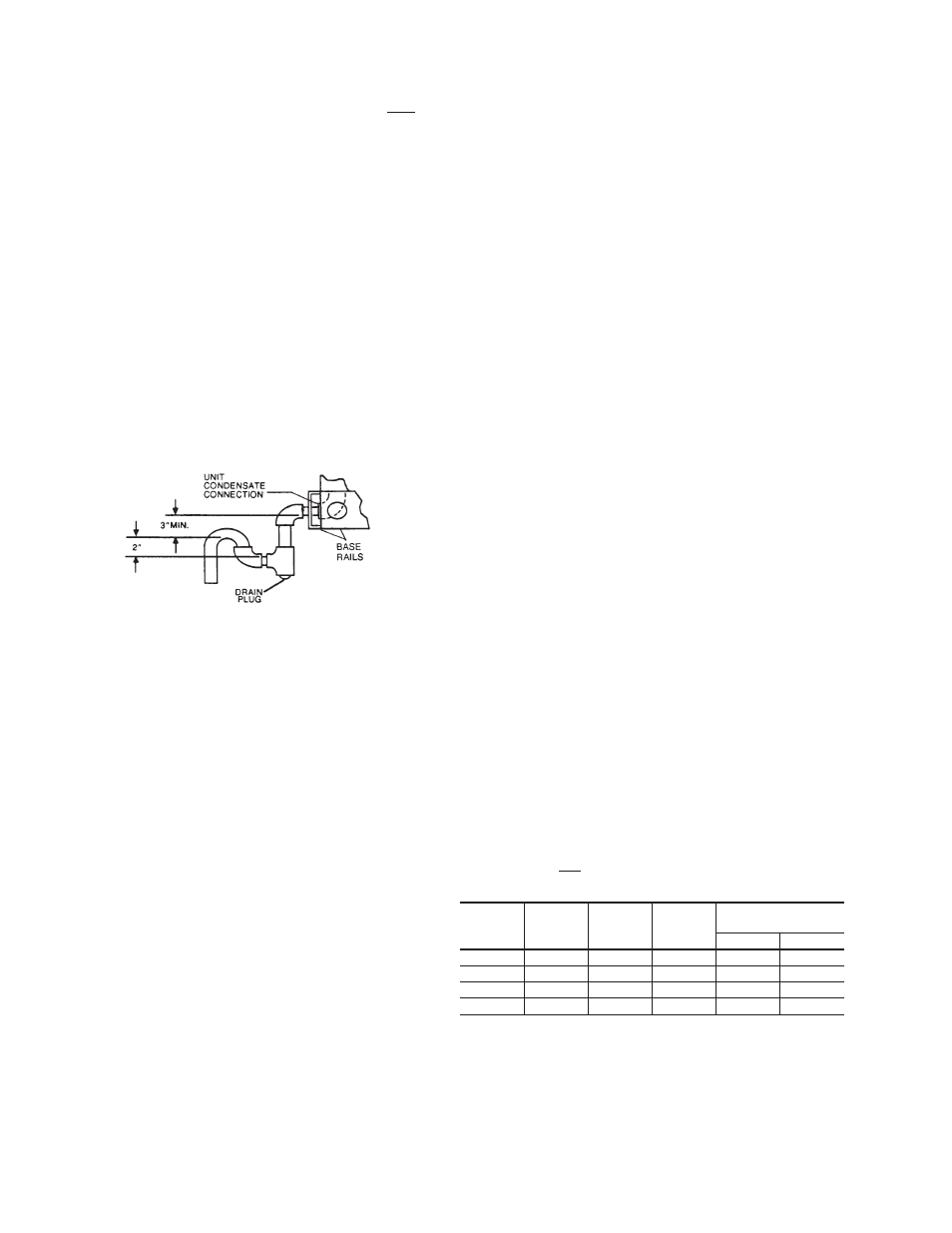

CONDENSATE DRAIN

Plumbing must conform to local codes. Use a sealing compound

on male pipe threads. Install a condensate drain line from the 3/4"

PVC female connection on the unit to spill into an open drain.

NOTE: The condensate drain line MUST be trapped to pro-

vide proper drainage. See Figure 2.

SERVICE ACCESS

Access to all serviceable components is provided by the

following removable panels:

•

Compressor compartment

•

Burner compartment

•

Blower compartment

•

Main control box

•

Filter compartment

•

Motor access (on units with belt-drive option)

Refer to Figure 9 for location of these access panels.

CAUTION: Make sure that all screws are replaced on the unit

to maintain an air-tight seal.

THERMOSTAT

The room thermostat should be located on an inside wall

approximately 56" above the floor where it will not be subject to

drafts, sun exposure, or heat from electrical fixtures or

appliances. Follow manufacturer's instructions enclosed with

thermostat for general installation procedure. Color coded

insulated wires (#18 AWG) should be used to connect

thermostat to unit. See Figure 3 for wiring details.

NOTE: If the unit has an economizer, remove jumper J1 from

terminals 8 and 10 on the relay board to prevent si-

multaneous operation of the compressor and the

economizer. If you want to energize the compressor

for supplemental cooling during the economizer op-

eration, use a thermostat with two stages of cooling.

POWER AND CONTROL WIRING

Field wiring to the unit must conform to provisions of the National

Electrical Code (NEC) ANSI/NFPA No. 70 and/or local

ordinances. The unit must be electrically grounded in

accordance with the NEC (as specified above) and/or local

codes.

Voltage tolerances which must be maintained at the

compressor terminals during start-up and running conditions

are indicated on the unit Rating Plate and Table 1.

The internal wiring harness furnished with this unit is an

integral part of a UL design certified unit. Field alteration to

comply with electrical codes should not be required.

A disconnect switch should be field provided for the unit. The

switch must be separate from all other circuits. Refer to Figure

9 for installation location. If any of the wire supplied with the unit

must be replaced, replacement wire must be of the type shown

on the wiring diagram.

Electrical lines must be sized properly to carry the load. USE

COPPER CONDUCTORS ONLY. Each unit must be wired

with a separate branch circuit fed directly from the meter panel

and properly protected.

CAUTION: When connecting electrical power and control wir-

ing to the unit, waterproof type connectors MUST

BE USED so that water or moisture cannot be

drawn into the unit during normal operation. The

above waterproofing conditions will also apply

when installing a field-supplied disconnect switch.

Refer to Figure 3 for typical field wiring and to the appropriate unit

wiring diagram for control circuit and power wiring information.

BLOWER SPEED SELECTION

Three blower motor speeds are available on the direct-drive

units. The speed selection for the direct-drive units is

determined by the CFM and ESP requirements of the

applications. All units with belt-drive option have an adjustable

motor pulley to achieve the above conditions.

All direct-drive units with 208/230 voltage are shipped with the

wire labeled #116 connected to the “HIGH” speed tap on the

blower motor. If a lower blower motor speed is desired, this wire

should be moved to the “MED” or “LOW” speed tap on the

motor for the speed desired.

All direct-drive units with 460 and 575 voltage are shipped with

the wire labeled #116 connected to the “HIGH” speed tap on

the blower motor. If the medium speed is required, connect

wire #116 to the “MED” speed tap and the blue motor lead to

the “HIGH” speed tap. If the low speed is required, connect wire

#116 to the “LOW” speed tap, the blue motor lead to the “HIGH”

speed tap and the orange motor lead to the “MED” speed tap.

COMPRESSORS

On some units the compressor is mounted on springs which

have been tightened down for shipment only.

After this unit is installed, back out the compressor bolts until

the sleeve clears the top grommet.

CAUTION: Do Not loosen compressor mounting bolts.

COMBUSTION DISCHARGE

The products of combustion are discharged horizontally

through a screened opening on the gas heat access panel.

035-14832-003-A-0204

4

Unitary Products Group

FIG. 2 - RECOMMENDED DRAIN PIPING

Input

Capacity,

(Mbh)

Output

Capacity,

(Mbh)

Available

on

Models

Gas Rate

1

(Ft.

3

/Hr.)

Temp. Rise °F

At Full Input

2

Min.

Max.

50

40

3 Ton

47

15

45

75

60

4 Ton

70

25

55

100

79

3/5 Ton

93

40/25

70/55

125

99

4/5 Ton

116

45/35

75/65

NOTE: Gas Heaters are shipped available for natural gas, but can be converted to L.P. with

Kit Model No. 1NP0434. All furnaces meet the latest California seasonal efficiency

requirements.

1Based on 1075 Btu/Ft

3

.

2The air flow must be adjusted to obtain a temperature rise within the range shown.

TABLE 2 - GAS HEAT APPLICATION DATA